Electrical machine control systems, often managed by programmable logic controllers (PLCs), are essential across various industries, enabling automation, efficiency, and safety in complex operations.

From manufacturing to healthcare, these systems play a crucial role in optimizing machine performance and ensuring seamless industrial processes. Below are some real-world applications of electrical machine control systems.

1. Industrial Automation and Manufacturing

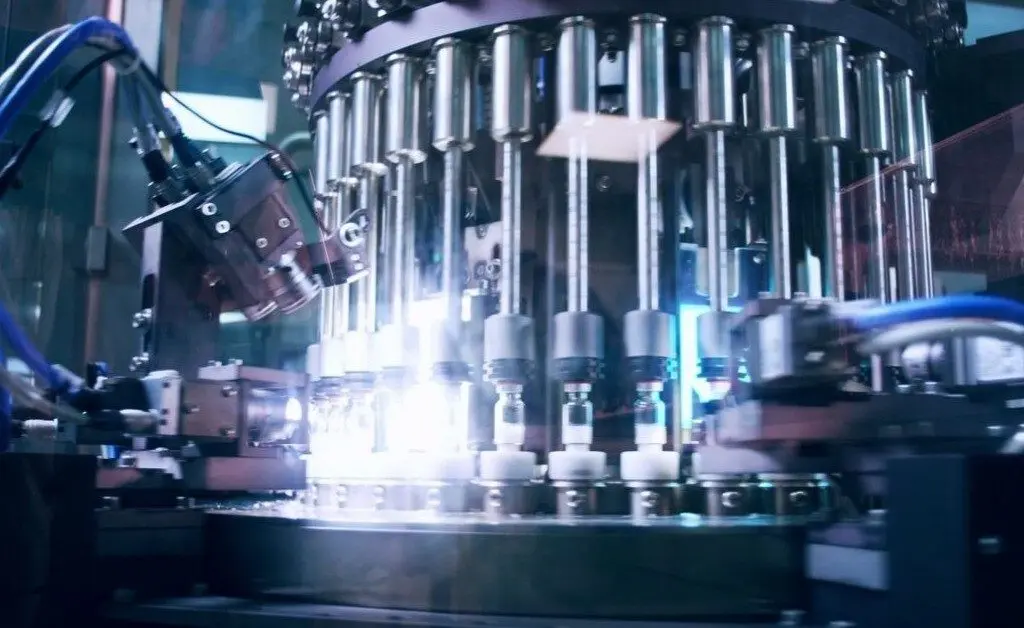

Manufacturing plants rely heavily on electrical machine control systems to streamline production processes. Key applications include:

- Robotic Assembly Lines: Automated machines equipped with sensors and controllers perform precise tasks such as welding, painting, and packaging.

- Conveyor Belt Systems: Control systems regulate the speed and movement of conveyor belts, ensuring smooth material handling and reducing bottlenecks.

- CNC Machines: Computer Numerical Control (CNC) machines use electrical control systems to perform high-precision machining operations.

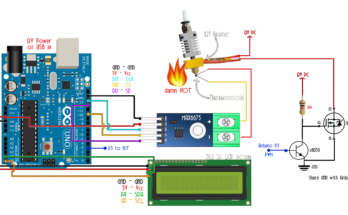

By integrating Programmable Logic Controllers (PLCs) and IoT technology, manufacturers enhance productivity, minimize waste, and improve product quality.

2. Energy and Power Systems

Electrical machine control systems play a vital role in power generation and distribution. Some applications include:

- Power Plants: Turbine control systems regulate energy production in thermal, hydro, and wind power plants.

- Smart Grids: Automated control systems optimize electricity distribution, reducing energy losses and improving reliability.

- Industrial Motors and Drives: Variable Frequency Drives (VFDs) control motor speed and torque, enhancing energy efficiency in industrial operations.

These applications contribute to more efficient and sustainable energy management worldwide.

3. Healthcare and Medical Equipment

The healthcare industry also benefits from electrical machine control systems, particularly in medical device automation. Key examples include:

- MRI and CT Scanners: Precise motor control ensures accurate imaging and patient safety.

- Robotic Surgery Systems: Automated surgical robots assist doctors in performing complex procedures with high precision.

- Hospital Automation: HVAC systems, patient monitoring devices, and automated drug dispensers rely on electrical control systems for efficiency and accuracy.

These advancements improve patient care, enhance medical accuracy, and streamline hospital operations.

Conclusion

Electrical machine control systems are transforming industries by enabling automation, improving efficiency, and enhancing safety. From manufacturing and energy to healthcare, these systems ensure smooth operations and increased productivity. As technology advances, the integration of AI, IoT, and smart automation will further expand their capabilities, driving industrial progress.