Enhancing machine performance is crucial for boosting efficiency, lowering operational expenses, and prolonging equipment life. Advanced control systems are key to this process, offering accurate control, automation, and continuous monitoring. By adopting effective strategies, machines can function at optimal levels, reducing downtime and increasing overall productivity.

1. Implementing Real-Time Monitoring and Data Analysis

Real-time monitoring empowers operators to observe machine performance continuously and identify inefficiencies early, preventing them from developing into serious problems. Incorporating safety measures into machine control systems is also critical, helping to safeguard personnel and equipment while maintaining operational integrity. Key benefits include:

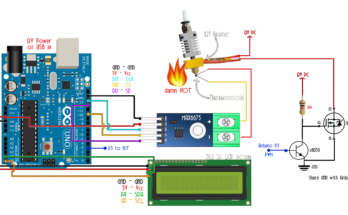

- Condition Monitoring: Sensors collect data on temperature, vibration, and power consumption to detect early signs of wear or failure.

- Predictive Maintenance: Data-driven insights help schedule maintenance before breakdowns occur, reducing unplanned downtime.

- Performance Optimization: Analyzing machine data helps fine-tune processes, improve energy efficiency, and maintain consistent output.

By leveraging Industrial Internet of Things (IIoT) technology, businesses can gain deeper insights into machine health and optimize operations proactively.

2. Enhancing Automation and Control Strategies

Modern automation and intelligent control techniques greatly enhance machine precision and operational efficiency. Automated control systems in manufacturing offer numerous advantages, such as increased productivity, reduced human error, and consistent quality output. Some key approaches include:

- Programmable Logic Controllers (PLCs): These enable precise control of machine operations, reducing errors and increasing consistency.

- Adaptive Control Systems: AI-powered systems adjust machine parameters dynamically to optimize performance under varying conditions.

- Motion Control Optimization: Fine-tuning motor speeds, acceleration, and positioning improves production accuracy and reduces wear on mechanical components.

A well-designed automation strategy ensures machines run at optimal performance while minimizing energy consumption and maintenance needs.

3. Improving System Integration and Communication

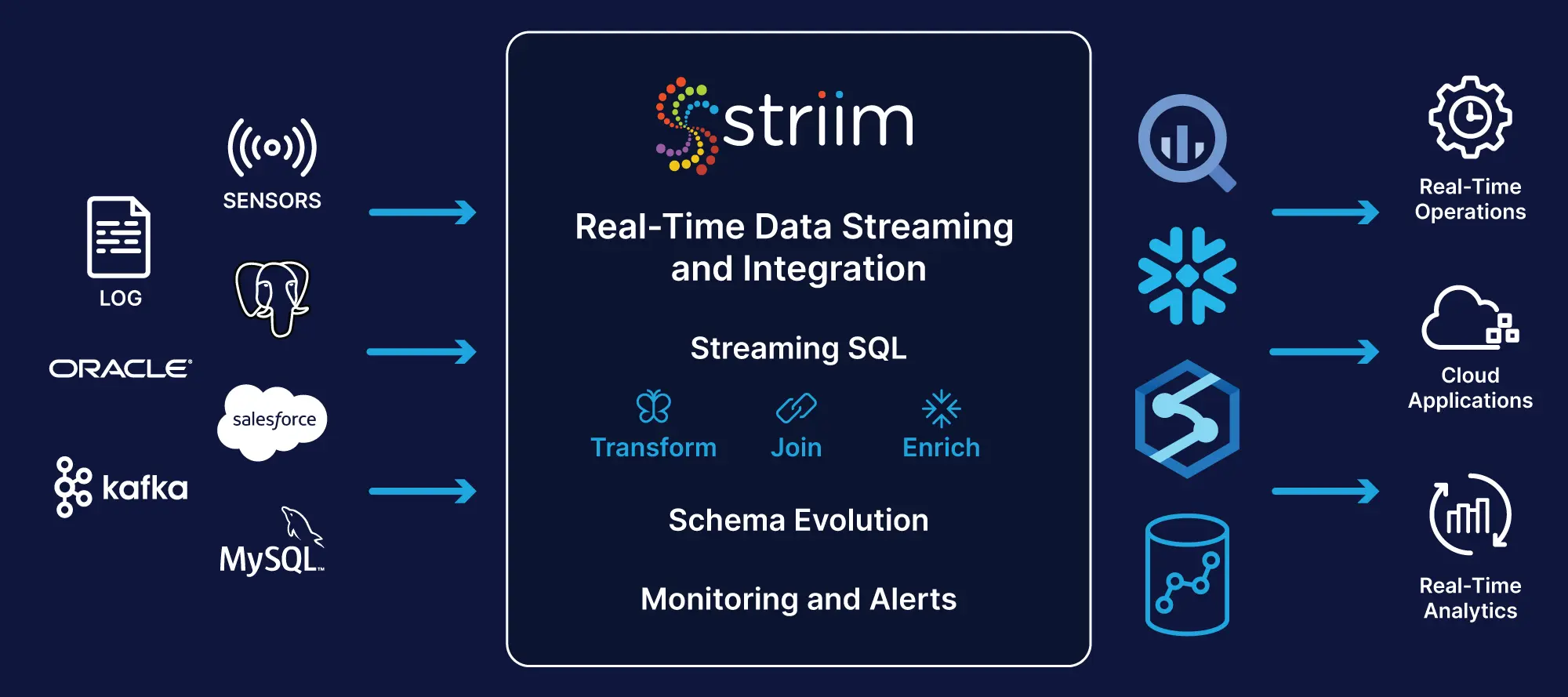

Seamless communication between machines and control systems enhances overall efficiency and responsiveness. Important aspects include:

- Integration with IoT and Cloud Systems: Connecting machines to cloud-based platforms enables remote monitoring and control.

- Standardized Communication Protocols: Using protocols like Modbus, OPC UA, and Ethernet/IP ensures compatibility between different control devices.

- Interconnected Systems: Machines that communicate in real-time can adjust processes dynamically, reducing delays and optimizing workflow.

Proper system integration improves machine coordination, reduces downtime, and enhances productivity in industrial settings.

Conclusion

Optimizing machine performance with control systems requires real-time monitoring, advanced automation, and seamless system integration. By implementing these strategies, businesses can increase efficiency, reduce costs, and improve overall equipment reliability. As technology continues to advance, adopting smart control solutions will be essential for staying competitive in modern industrial environments.