As industries evolve, electrical machine control systems are becoming more advanced, efficient, and intelligent.

Emerging technologies such as artificial intelligence (AI), the Internet of Things (IoT), and automation are reshaping the future of machine control. These innovations enhance productivity, reduce downtime, and improve overall system performance.

1. Artificial Intelligence and Machine Learning in Control Systems

AI and machine learning are revolutionizing electrical machine control by enabling predictive maintenance, adaptive control, and self-optimization. Some key advancements include:

- Predictive Maintenance: AI analyzes data from sensors to detect potential failures before they occur, reducing downtime and maintenance costs.

- Self-Learning Systems: Machine learning algorithms allow machines to adapt to changing conditions, optimizing performance without human intervention.

- Enhanced Fault Detection: AI-driven control systems can quickly identify and correct errors, improving operational efficiency.

These AI-based innovations help industries enhance automation and achieve smarter machine control.

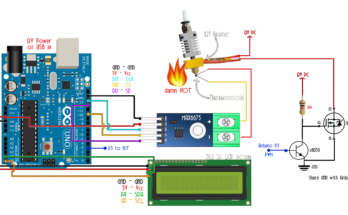

2. IoT-Enabled Smart Machine Control

The adoption of IoT in automated machine systems is revolutionizing industrial operations by enabling real-time insights, remote accessibility, and smarter decision-making based on data analysis. This digital transformation also opens up opportunities for AI-powered business ideas that require no coding skills, allowing entrepreneurs to leverage automation and smart technologies with minimal technical barriers. IoT is reshaping machine automation in the following ways:

- Remote Monitoring: Operators can track machine performance and detect issues from anywhere using cloud-based platforms.

- Data-Driven Optimization: IoT devices collect and analyze data to improve efficiency, reduce energy consumption, and extend machine lifespan.

- Interconnectivity: Machines can communicate with each other, allowing seamless coordination in manufacturing processes.

IoT-driven control systems provide greater flexibility, reliability, and efficiency in industrial operations.

3. The Rise of Automation and Robotics

Automation and robotics are playing a crucial role in the future of machine by increasing speed, precision, and safety. Some key trends include:

- Collaborative Robots (Cobots): These robots work alongside humans, improving productivity without replacing the workforce.

- Autonomous Machine Control: Fully automated systems can make real-time decisions and adjustments without human intervention.

- Advanced Motion Control: High-speed and precision control systems improve the accuracy of robotic arms, conveyor belts, and automated machinery.

As automation continues to evolve, industries will experience higher efficiency, reduced labor costs, and improved safety standards.

Conclusion

The future of electrical machine is being shaped by AI, IoT, and automation. These advancements are making industrial processes smarter, more efficient, and highly reliable. As technology continues to progress, businesses that embrace these innovations will stay ahead in a rapidly changing industrial landscape.