Industrial operations are entering an era of unparalleled innovation, driven by the transformative power of the Internet of Things (IoT). Among its myriad applications, IoT-based condition monitoring systems stand out as game-changers for managing industrial equipment. Imagine a world where machines “talk” to each other, predict failures, and optimize their own performance that’s the promise of IoT-based condition monitoring.

What Are IoT-Based Condition Monitoring Systems?

IoT-based condition monitoring systems are advanced setups that use IoT sensors and devices to track the real-time status of industrial equipment. By continuously monitoring variables such as temperature, vibration, pressure, and humidity, these systems help detect anomalies, predict potential failures, and enhance operational efficiency.

Why Are These Systems a Big Deal?

Think of industrial equipment as the heartbeat of manufacturing plants and factories. If a critical machine fails unexpectedly, the ripple effects can disrupt the entire production line. Traditional maintenance methods often rely on periodic checks or reactive measures, but IoT-based condition monitoring allows for predictive maintenance ensuring issues are tackled before they escalate.

How Do IoT Monitoring Systems Work?

At the core of these systems lies a network of IoT sensors. Here’s how it all comes together:

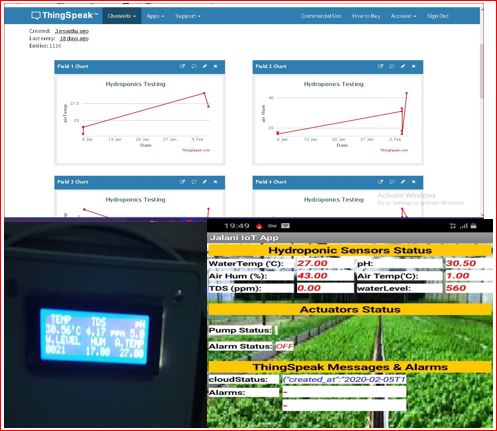

- Data Collection: Sensors collect data on equipment conditions, such as temperature, pressure, and vibration.

- Data Transmission: Collected data is sent to a central hub using wireless communication protocols like Wi-Fi, Bluetooth, or LoRaWAN.

- Data Analysis: Cloud-based platforms analyze this data using AI and machine learning to identify trends and anomalies.

- Actionable Insights: These insights trigger alerts, informing operators of potential issues or optimization opportunities.

Key Features of IoT-Based Condition Monitoring

1. Real-Time Monitoring

Say goodbye to manual checks. IoT systems provide up-to-the-minute updates, empowering businesses to stay ahead of potential problems.

2. Predictive Analytics

Harnessing AI-driven algorithms, these systems predict failures before they occur, ensuring timely interventions.

3. Remote Access

Operators can monitor equipment from anywhere via apps or web dashboards, enhancing convenience and flexibility.

4. Scalability

IoT solutions can grow with your business, accommodating new machines and expanding operations effortlessly.

Benefits of IoT Condition Monitoring

1. Enhanced Equipment Lifespan

By identifying issues early, IoT systems prevent damage, extending the life of expensive machinery.

2. Reduced Downtime

Predictive maintenance minimizes unexpected breakdowns, ensuring smoother operations.

3. Cost Savings

Lower repair costs and optimized performance translate into significant savings over time.

4. Improved Safety

IoT systems detect hazardous conditions, ensuring a safer working environment.

Popular Use Cases

Manufacturing Plants

IoT monitoring is revolutionizing manufacturing by enabling seamless tracking of critical assets such as conveyor belts and CNC machines.

Oil and Gas

From pipeline monitoring to offshore drilling equipment, IoT systems play a crucial role in maintaining safety and efficiency in this high-risk industry.

Power Generation

Power plants leverage IoT to monitor turbines, generators, and transformers, ensuring uninterrupted energy supply.

Food and Beverage

IoT sensors maintain the quality of perishable goods by monitoring refrigeration units and production lines.

Overcoming Challenges in Implementation

While the benefits are undeniable, implementing IoT condition monitoring comes with its challenges:

- Integration with Legacy Systems: Many industrial facilities still operate older equipment that may not easily integrate with IoT technologies.

- Data Security: Ensuring the safety of data transmitted over IoT networks is a critical concern.

- Cost of Deployment: The initial investment in IoT infrastructure can be high, though long-term ROI often justifies the expense.

- Skill Gaps: Employees may require training to adapt to these advanced systems.

Choosing the Right IoT Monitoring Solution

When selecting an IoT-based condition monitoring system, consider the following:

- Sensor Compatibility: Ensure the sensors can monitor the specific parameters required by your equipment.

- Data Analysis Capabilities: Look for platforms offering robust analytics and actionable insights.

- Scalability: Choose solutions that can grow with your operational needs.

- User Interface: A user-friendly interface is essential for efficient operation and quick learning.

The Role of Artificial Intelligence in IoT Monitoring

AI takes IoT-based condition monitoring to the next level. By analyzing massive datasets, AI algorithms identify patterns and anomalies that human operators might miss. This combination of IoT and AI not only enhances predictive maintenance but also drives continuous process optimization.

Case Study: Success with IoT Monitoring

Company: XYZ Manufacturing

Challenge: Frequent downtime due to unexpected machine failures.

Solution: XYZ implemented an IoT-based condition monitoring system across its assembly line. Sensors tracked vibration and temperature data in real-time, alerting operators to unusual trends.

Results:

- 30% reduction in unplanned downtime.

- 20% savings in maintenance costs.

- Improved equipment reliability and production efficiency.

The Future of IoT-Based Condition Monitoring

The future is bright for IoT monitoring systems. Emerging trends include:

- Edge Computing: Processing data closer to the source to reduce latency and improve decision-making speed.

- 5G Connectivity: Faster and more reliable communication between devices.

- Sustainability: Using IoT to monitor energy consumption and reduce the environmental impact of industrial operations.

Common Myths About IoT Monitoring

1. “It’s Too Expensive”

While the upfront costs can be high, the long-term savings in maintenance and downtime make it a worthwhile investment.

2. “It’s Only for Large Companies”

IoT solutions are increasingly accessible to small and medium-sized enterprises (SMEs) thanks to scalable and cost-effective options.

3. “It’s Difficult to Use”

Modern IoT platforms prioritize user-friendliness, making it easy for teams to adopt and leverage these technologies.

How to Get Started with IoT Condition Monitoring

- Identify Pain Points: Pinpoint the areas where equipment failure impacts your operations the most.

- Set Goals: Define clear objectives for implementing IoT monitoring, such as reducing downtime or cutting maintenance costs.

- Partner with Experts: Work with IoT providers who have experience in your industry.

- Start Small: Begin with a pilot project before scaling up.

Conclusion

IoT-based condition monitoring systems represent a quantum leap in industrial equipment management, empowering businesses to operate smarter, safer, and more efficiently. By enabling predictive maintenance, reducing downtime, and optimizing operational efficiency, these systems are transforming industries worldwide. As technology continues to advance, incorporating AI, edge computing, and 5G connectivity, the potential for IoT monitoring systems will only grow. The question isn’t whether to adopt this technology it’s when.

FAQs About IoT-Based Condition Monitoring

1. What types of equipment can benefit from IoT condition monitoring?

Most industrial equipment, including motors, compressors, pumps, and turbines, can benefit from IoT monitoring. The key is selecting sensors suited to the specific equipment type.

2. How does IoT-based condition monitoring save money?

By reducing unexpected breakdowns and optimizing maintenance schedules, businesses save on repair costs and lost productivity.

3. Is IoT condition monitoring secure?

Yes, reputable providers use encryption, firewalls, and secure communication protocols to safeguard data.

4. Can IoT monitoring be integrated with existing systems?

Yes, many IoT solutions are designed to work alongside legacy systems with minimal disruption.

5. What is the ROI for IoT condition monitoring?

While results vary, companies often see ROI within the first year due to reduced downtime and maintenance costs.