RFID-based access control with a disinfectant booth is a security system that uses radio frequency identification (RFID) technology to control access to a building or room, while also disinfecting people who enter. RFID tags are small, electronic devices that can be attached to people’s clothing or carried on their person. When an RFID tag passes through an RFID reader, the reader can identify the tag and the person carrying it.

In this project design, RFID-Based Access Control with Disinfectant Booth, we design and construct model of an RFID based access control booth that can be placed at the entrance of a door. It will give only people with the permitted RFID card access to pass and once these people enter the model booth, it will activate the spraying of a disinfectant fog that will sanitize the people. For example, this RFID-based access control system could be used to track employee attendance or to track patients in a hospital.

A disinfectant booth is a device that sprays people with disinfectant as they pass through it. This can help to prevent the spread of diseases such as COVID-19. An RFID-based access control system with a disinfectant booth can be used to ensure that only authorized people enter a building or room, and that those people are disinfected before they enter. This can help to improve security and reduce the risk of spreading diseases.

Here are some of the benefits of using an RFID-based access control system with a disinfectant booth

- Improved security: RFID-based access control systems can help to improve security by preventing unauthorized people from entering a building or room.

- Reduced risk of spreading diseases: Disinfectant booths can help to reduce the risk of spreading diseases by spraying people with disinfectant as they pass through.

- Increased efficiency: RFID-based access control systems can help to increase efficiency by automating the process of granting access to people.

- Improved data collection: RFID-based access control systems can be used to collect data about people’s movements and activities. This data can be used to improve security, efficiency, and decision-making.

How to Design An RFID-Based Access Control with Disinfectant Booth

The Components Needed

| Components | Quantity |

|---|---|

| Cubicle booth of suitable size | 1 |

| L298N Module | 1 |

| stepper motor | 1 |

| Double Channel Relay module | 1 |

| 12V DC Power Supply | 1 |

| 220V AC pump | 1 |

| 900W Fogging Heater | 1 |

| Threaded 40cm Rod | 1 |

| RFID module MFRC522 | 1 |

| Arduino Mega Dev Board | 1 |

| 1602 LCD module | 1 |

| RFID tags or Debit Cards | 4 |

| 3×6 inch box | 1 |

| LCD connector Wire | 1 |

| miscellaneous | 6 |

Read

- How to Design Fire Detection And Video Surveillance Project

- IoT Based Carbon Monoxide and Carbon Dioxide Monitoring Device

- IoT Generator Monitoring Using Arduino and RemoteXY

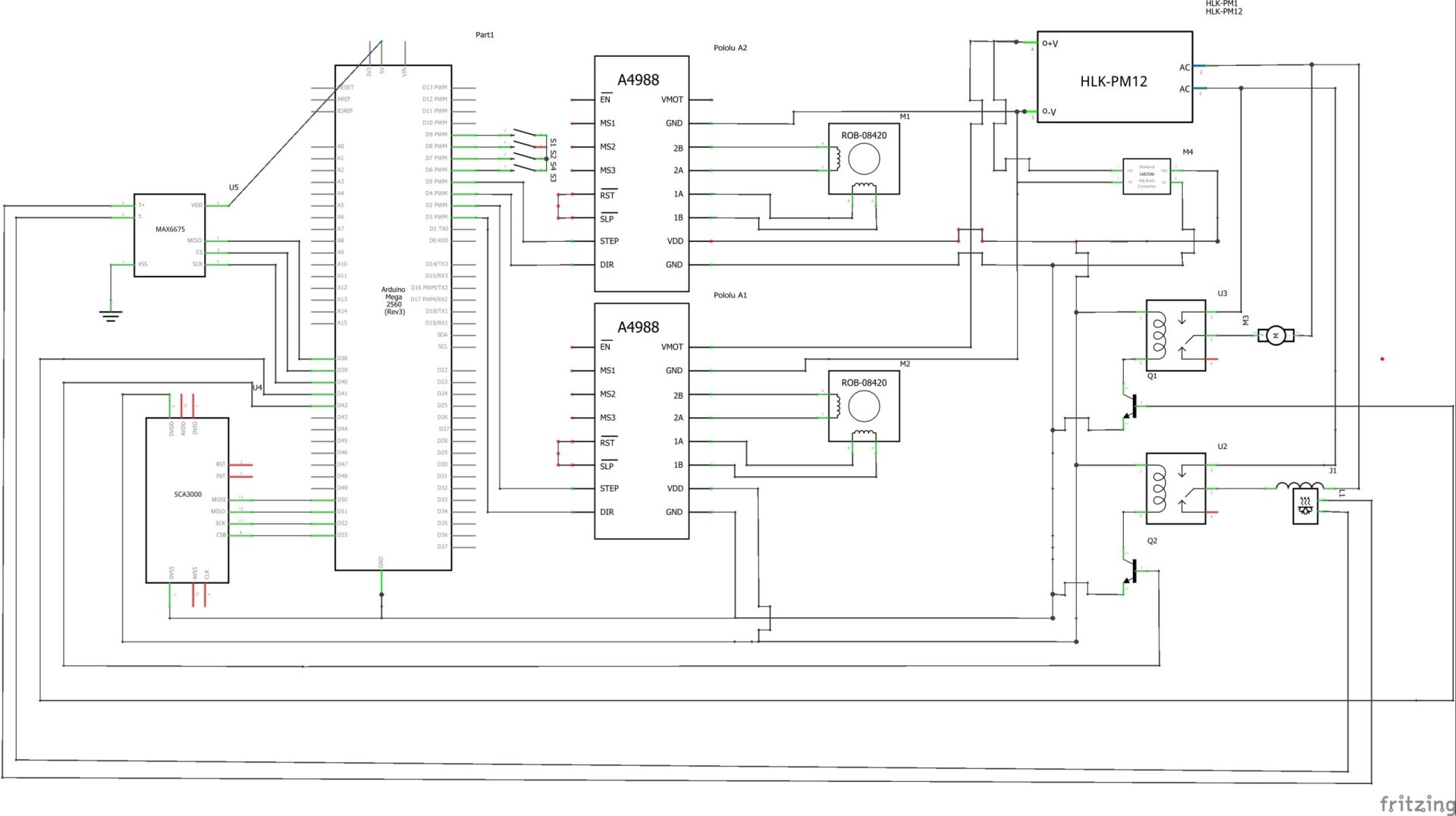

RFID-Based Access Control With Disinfectant Booth: The Schematic Diagram

Explanation of Circuit Diagram

The circuit diagram shown above used the Arduino Mega board as the brain of the project design. The Arduino mega board controls the 2 channel relays from an IO pin. One of the relays is needed to pump disinfectant liquid when the fog heater is hot enough the other is needed to control the fog heater from excess heat and damage. The Fog heater comes with a thermostat that we can use to cut off AC voltage supply to the fog heater when it is hot enough.

We used the L298N motor driver module that is made up A4988 IC to control the stepper motor to slide the door forward to ensure closing of the booth model door and backwards to simulate opening of the door. This action would be made possible by the thread roll machine system that is being controlled by the stepper motor.

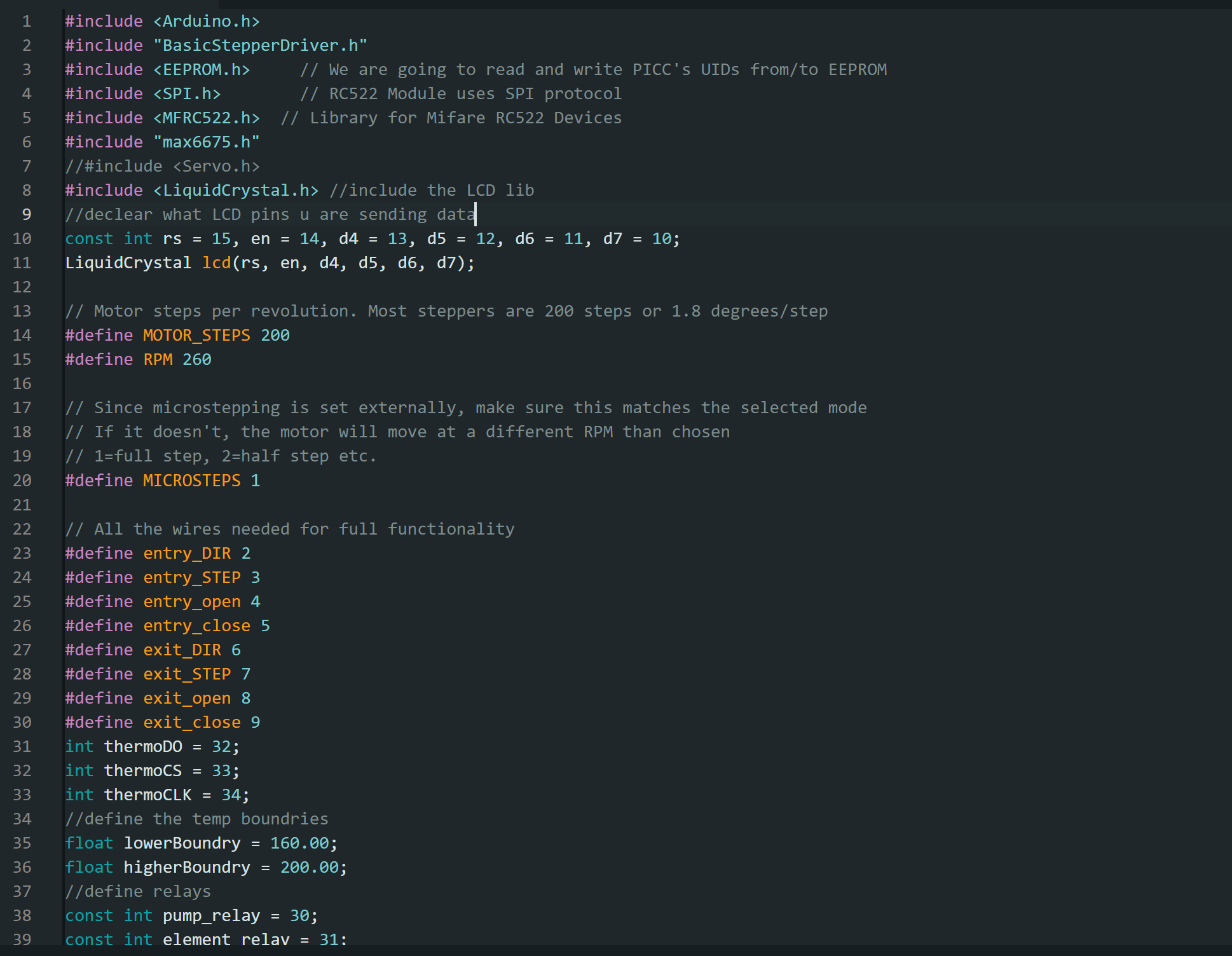

The Arduino Sketch for The Project Design

#include <Arduino.h>

#include "BasicStepperDriver.h"

#include <EEPROM.h> // We are going to read and write PICC's UIDs from/to EEPROM

#include <SPI.h> // RC522 Module uses SPI protocol

#include <MFRC522.h> // Library for Mifare RC522 Devices

#include "max6675.h"

//#include <Servo.h>

#include <LiquidCrystal.h> //include the LCD lib

//declear what LCD pins u are sending data

const int rs = 15, en = 14, d4 = 13, d5 = 12, d6 = 11, d7 = 10;

LiquidCrystal lcd(rs, en, d4, d5, d6, d7);

// Motor steps per revolution. Most steppers are 200 steps or 1.8 degrees/step

#define MOTOR_STEPS 200

#define RPM 260

// Since microstepping is set externally, make sure this matches the selected mode

// If it doesn't, the motor will move at a different RPM than chosen

// 1=full step, 2=half step etc.

#define MICROSTEPS 1

// All the wires needed for full functionality

#define entry_DIR 2

#define entry_STEP 3

#define entry_open 4

#define entry_close 5

#define exit_DIR 6

#define exit_STEP 7

#define exit_open 8

#define exit_close 9

int thermoDO = 32;

int thermoCS = 33;

int thermoCLK = 34;

//define the temp boundries

float lowerBoundry = 160.00;

float higherBoundry = 200.00;

//define relays

const int pump_relay = 30;

const int element_relay = 31;

//define motion sensor pin

const int motion_pin = 48;

//define lcd backlight pin

const int lcd_pin = 47;

//define some variables to store data used in the program

float temp;

int On = LOW; // Active Low relay used, LOW will mean ON.

int Off = HIGH; // Active low relay used.

// Create MFRC522 instance.

#define SS_PIN 53

#define RST_PIN 49

MFRC522 mfrc522(SS_PIN, RST_PIN);

MAX6675 thermocouple(thermoCLK, thermoCS, thermoDO);

bool programMode = false; // initialize programming mode to false

uint8_t successRead; // Variable integer to keep if we have Successful Read from Reader

byte storedCard[4]; // Stores an ID read from EEPROM

byte readCard[4]; // Stores scanned ID read from RFID Module

byte masterCard[4]; // Stores master card's ID read from EEPROM

// 2-wire basic config, microstepping is hardwired on the driver

BasicStepperDriver entry_door(MOTOR_STEPS, entry_DIR, entry_STEP);

BasicStepperDriver exit_door(MOTOR_STEPS, exit_DIR, exit_STEP);

bool motion(){

if(digitalRead(motion_pin) == HIGH){

return true;

}

else{return false;}

}

void lcd_light(int state){

digitalWrite(lcd_pin, state);

}

bool open_entry(){

while(1){

entry_door.rotate(360);

Serial.println("Opening Entry Door..");

lcd.setCursor(0, 1);

lcd.print("Opening Entry....");

if(digitalRead(entry_open) == LOW){

entry_door.stop();

Serial.println("Door Stopped");

return true;

}

}

}

bool open_exit(){

while(1){

exit_door.rotate(360);

Serial.println("Opening Exit Door..");

lcd.setCursor(0, 1);

lcd.print("Opening Exit....");

if(digitalRead(exit_open) == LOW){

exit_door.stop();

Serial.println("Door Stopped");

return true;

}

}

}

bool close_entry(){

while(1){

entry_door.rotate(-360);

Serial.println("Closing Entry Door..");

lcd.setCursor(0, 1);

lcd.print("Closing Entry...");

if(digitalRead(entry_close) == LOW){

entry_door.stop();

Serial.println("Door Stopped");

return true;

}

}

}

bool close_exit(){

while(1){

exit_door.rotate(-360);

Serial.println("Closing Exit Door..");

lcd.setCursor(0, 1);

lcd.print("Closing Exit....");

if(digitalRead(exit_close) == LOW){

exit_door.stop();

Serial.println("Door Stopped");

return true;

}

}

}

void grant_access(){

Serial.println("Access Granted, wait for door to open");

if(open_entry() == true){

Serial.println("Door Open Please Enter");

delay(1500);

}

if(close_entry() == true){

Serial.println("Disinfecting.....");

Pump(On);

delay(1500);

Pump(Off);

delay(1000);

}

if(open_exit() == true){

Serial.println("Door Open please exit");

delay(1500);

}

if (close_exit() == true){

Serial.println("all good");

}

}

void setup()

{

//define the mode of the pins, either input or output

pinMode(entry_open, INPUT_PULLUP);

pinMode(entry_close, INPUT_PULLUP);

pinMode(exit_open, INPUT_PULLUP);

pinMode(exit_close, INPUT_PULLUP);

pinMode(exit_close, INPUT_PULLUP);

pinMode(motion_pin, INPUT_PULLUP);

pinMode(lcd_pin, OUTPUT);

pinMode(pump_relay, OUTPUT);

pinMode(element_relay, OUTPUT);

entry_door.begin(RPM, MICROSTEPS);

exit_door.begin(RPM, MICROSTEPS);

Serial.begin(9600);

// Initiate SPI bus

SPI.begin();

// Initiate MFRC522

mfrc522.PCD_Init();

//begin the LCD

lcd.begin(16, 2);

//turn all pins off at initial.(Active low relay, so HIGH means off)

Pump(Off);

Heater(Off);

Serial.println(F("Smartech Access Control v0.2")); // For debugging purposes

ShowReaderDetails(); // Show details of PCD - MFRC522 Card Reader details

lcd_light(HIGH);

//Print welcome message

lcd.println(" Ayoola's NFC: ");

lcd.setCursor(0, 1);

lcd.println("Sanitizing Boot ");

delay(3000);

Serial.println("Auto Disinfectant Booth");

//close_entry();

temp = thermocouple.readCelsius();

lcd.clear();

int i = 0;

while(temp < lowerBoundry+20){

temp = thermocouple.readCelsius();

Serial.print("Heatig up, Please be patient! ");

lcd.setCursor(0, 0);

lcd.print(" Heating Up ");

lcd.setCursor(i, 1);

lcd.print("*");

Serial.print(temp);

Serial.println("'C");

Heater(On);

delay(2000);

i++;

if(i >= 15){

i = 0;

lcd.clear();

}

}

Heater(Off);

if (EEPROM.read(1) != 123) {

Serial.println(F("No Master Card Defined"));

Serial.println(F("Scan A PICC to Define as Master Card"));

lcd.setCursor(0, 0);

lcd.println("No Master CARD.! ");

delay(1500);

lcd.setCursor(0, 1);

lcd.println("Swipe a CARD to:");

delay(2000);

lcd.setCursor(0, 0);

lcd.println("Swipe a CARD to:");

delay(1500);

lcd.setCursor(0, 1);

lcd.println(" Save as Master!");

delay(500);

do {

successRead = getID(); // sets successRead to 1 when we get read from reader otherwise 0

} while (!successRead); // Program will not go further while you not get a successful read

for ( uint8_t j = 0; j < 4; j++ ) { // Loop 4 times

EEPROM.write( 2 + j, readCard[j] ); // Write scanned PICC's UID to EEPROM, start from address 3

}

EEPROM.write(1, 123); // Write to EEPROM we defined Master Card.

//EEPROM.write(0, 1); // Write to EEPROM to save card count.

Serial.println(F("Master Card Defined"));

lcd.clear();

lcd.setCursor(0, 0);

lcd.println("Master Tag Saved ");

delay(1500);

lcd.setCursor(0, 1);

lcd.println("Keep it Securely! ");

delay(2500);

}

Serial.println(F("-------------------"));

Serial.println(F("Master Card's UID"));

for ( uint8_t i = 0; i < 4; i++ ) { // Read Master Card's UID from EEPROM

masterCard[i] = EEPROM.read(2 + i); // Write it to masterCard

Serial.print(masterCard[i], HEX);

}

Serial.println("");

Serial.println(F("-------------------"));

Serial.println(F("Everything is ready"));

Serial.println(F("Waiting PICCs to be scanned"));

lcd.clear();

lcd.setCursor(0, 0);

lcd.println("Device is Ready ");

delay(2000);

lcd.clear();

}

void loop() {

do{

successRead = getID(); // sets successRead to 1 when we get read from reader otherwise 0

lcd.setCursor(0, 0);

lcd.print("Swipe a Tag to:");

lcd.setCursor(0, 1);

lcd.print(" gain access ");

temp = temp = thermocouple.readCelsius();

Serial.print("Temp = ");

Serial.print(temp);

Serial.println("'C ");

// For the MAX6675 to update, you must delay AT LEAST 250ms between reads!

delay(250);

if(temp <= lowerBoundry){

Heater(On);

Serial.println("Heating up.........");

}

else if(temp >= higherBoundry){

Heater(Off);

}

}while(!successRead);

if(successRead){

lcd.clear();

lcd.setCursor(0,0);

lcd.print("Checking card... ");

delay(2000);

if ( isMaster(readCard)) { // If scanned card's ID matches Master Card's ID - enter program mode

Serial.println(F("Welcome Master - Your Fare is free!"));

uint8_t count = EEPROM.read(0); // Read the first Byte of EEPROM that

Serial.print(F("I have ")); // stores the number of ID's in EEPROM

Serial.print(count);

Serial.print(F(" record(s) on EEPROM"));

Serial.println("");

lcd.setCursor(0,1);

lcd.print(" Welcome Master ");

delay(2000);

//card = false;

do{

successRead = getID(); // sets successRead to 1 when we get read from reader otherwise 0

lcd.setCursor(0,0);

lcd.print("Add New a Tag or ");

//delay(1000);

lcd.setCursor(0,1);

lcd.print(" Delete old Tag ");

Serial.println("Place a Card to allow register or a known card to delete");

//delay(1000);

} while (!successRead); //the program will not go further while you are not getting a successful read

if ( isMaster(readCard)) { // If scanned card's ID matches Master Card's ID - enter program mode

lcd.setCursor(0,0);

lcd.print("Tag Registration ");

lcd.setCursor(0,1);

lcd.print("Exited by Master ");

delay(3000);

//card = true;

return;

}

else if ( findID(readCard) ) { // If card found, see if the card is in the EEPROM

Serial.println(F("Tag was saved before, not a new tag"));

deleteID(readCard);

lcd.setCursor(0,0);

lcd.print(" Tag Existed " );

lcd.setCursor(0,1);

lcd.print("Deleting Tag...... ");

deleteID(readCard);

delay(3000);

}

else if ( !findID(readCard)){ // If scanned card is not known add it

Serial.println(F("I do not know this PICC, adding..."));

lcd.setCursor(0,0);

lcd.print(" Please wait " );

lcd.setCursor(0,1);

lcd.print(" Saving Tag.......");

delay(2000);

writeID(readCard);

if(writeID(readCard)){

Serial.println(F("-----------------------------"));

Serial.println(F("Scan a PICC to ADD or REMOVE to EEPROM"));

lcd.setCursor(0,1);

lcd.print(" Tag saved OK! ");

delay(3000);

}

else{

lcd.setCursor(0,0);

lcd.print("Error Saving Tag");

lcd.setCursor(0,1);

lcd.print("Pls. Try Again.. ");

delay(5000);

return;

}

}

}

else if ( findID(readCard) ) { // check if the card is in the EEPROM

Serial.println(F("Welcome Passenger"));

lcd.setCursor(0,0);

lcd.print("Valid Tag Swiped");

lcd.setCursor(0,1);

delay(2000);

lcd.print("*Access Granted*** ");

delay(3000);

//granted(2000);

grant_access();

}

else if( !findID(readCard) ){ // If scanned card is not known dont allow

Serial.println(F("I do not know this Tag, no entry"));

lcd.setCursor(0,0);

lcd.print(" Access Denied! " );

lcd.setCursor(0,1);

lcd.print("**Unknown Tag!** ");

delay(2000);

lcd.print("Buy a Legit Tag. ");

delay(3000);

}

}

}

void Pump(int state){

digitalWrite(pump_relay, state);

}

void Heater(int state){

digitalWrite(element_relay, state);

}

///////////////////////////////////////// Get PICC's UID ///////////////////////////////////

uint8_t getID() {

// Getting ready for Reading PICCs

if ( ! mfrc522.PICC_IsNewCardPresent()) { //If a new PICC placed to RFID reader continue

return 0;

}

if ( ! mfrc522.PICC_ReadCardSerial()) { //Since a PICC placed get Serial and continue

return 0;

}

// There are Mifare PICCs which have 4 byte or 7 byte UID care if you use 7 byte PICC

// I think we should assume every PICC as they have 4 byte UID

// Until we support 7 byte PICCs

Serial.println(F("Scanned PICC's UID:"));

for ( uint8_t i = 0; i < 4; i++) { //

readCard[i] = mfrc522.uid.uidByte[i];

Serial.print(readCard[i], HEX);

}

Serial.println("");

mfrc522.PICC_HaltA(); // Stop reading

return 1;

}

void ShowReaderDetails() {

// Get the MFRC522 software version

byte v = mfrc522.PCD_ReadRegister(mfrc522.VersionReg);

Serial.print(F("MFRC522 Software Version: 0x"));

Serial.print(v, HEX);

if (v == 0x91)

Serial.print(F(" = v1.0"));

else if (v == 0x92)

Serial.print(F(" = v2.0"));

else

Serial.print(F(" (unknown),probably a chinese clone?"));

Serial.println("");

// When 0x00 or 0xFF is returned, communication probably failed

if ((v == 0x00) || (v == 0xFF)) {

Serial.println(F("WARNING: Communication failure, is the MFRC522 properly connected?"));

Serial.println(F("SYSTEM HALTED: Check connections.")); // Turn on red LED

while (true); // do not go further

}

}

//////////////////////////////////////// Read an ID from EEPROM //////////////////////////////

void readID( uint8_t number ) {

uint8_t start = (number * 4 ) + 2; // Figure out starting position

for ( uint8_t i = 0; i < 4; i++ ) { // Loop 4 times to get the 4 Bytes

storedCard[i] = EEPROM.read(start + i); // Assign values read from EEPROM to array

}

}

///////////////////////////////////////// Add ID to EEPROM ///////////////////////////////////

bool writeID( byte a[] ) {

if ( !findID( a ) ) { // Before we write to the EEPROM, check to see if we have seen this card before!

uint8_t num = EEPROM.read(0); // Get the numer of used spaces, position 0 stores the number of ID cards

uint8_t start = ( num * 4 ) + 6; // Figure out where the next slot starts

for ( uint8_t j = 0; j < 4; j++ ) { // Loop 4 times

EEPROM.write( start + j, a[j] ); // Write the array values to EEPROM in the right position

}

//successWrite();

num++; // Increment the counter by one

EEPROM.write( 0, num ); // Write the new count to the counter

Serial.println(F("Succesfully added ID record to EEPROM"));

return true;

}

else {

//failedWrite();

Serial.println(F("Failed! There is something wrong with ID or bad EEPROM"));

return false;

}

}

///////////////////////////////////////// Remove ID from EEPROM ///////////////////////////////////

void deleteID( byte a[] ) {

if ( !findID( a ) ) { // Before we delete from the EEPROM, check to see if we have this card!

//failedWrite(); // If not

Serial.println(F("Failed! There is something wrong with ID or bad EEPROM"));

}

else {

uint8_t num = EEPROM.read(0); // Get the numer of used spaces, position 0 stores the number of ID cards

uint8_t slot; // Figure out the slot number of the card

uint8_t start; // = ( num * 4 ) + 6; // Figure out where the next slot starts

uint8_t looping; // The number of times the loop repeats

uint8_t j;

uint8_t count = EEPROM.read(0); // Read the first Byte of EEPROM that stores number of cards

slot = findIDSLOT( a ); // Figure out the slot number of the card to delete

start = (slot * 4) + 2;

looping = ((num - slot) * 4);

num--; // Decrement the counter by one

EEPROM.write( 0, num ); // Write the new count to the counter

for ( j = 0; j < looping; j++ ) { // Loop the card shift times

EEPROM.write( start + j, EEPROM.read(start + 4 + j)); // Shift the array values to 4 places earlier in the EEPROM

}

for ( uint8_t k = 0; k < 4; k++ ) { // Shifting loop

EEPROM.write( start + j + k, 0);

}

//successDelete();

Serial.println(F("Succesfully removed ID record from EEPROM"));

}

}

///////////////////////////////////////// Check Bytes ///////////////////////////////////

bool checkTwo ( byte a[], byte b[] ) {

for ( uint8_t k = 0; k < 4; k++ ) { // Loop 4 times

if ( a[k] != b[k] ) { // IF a != b then false, because: one fails, all fail

return false;

}

}

return true;

}

///////////////////////////////////////// Find Slot ///////////////////////////////////

uint8_t findIDSLOT( byte find[] ) {

uint8_t count = EEPROM.read(0); // Read the first Byte of EEPROM that

for ( uint8_t i = 1; i <= count; i++ ) { // Loop once for each EEPROM entry

readID(i); // Read an ID from EEPROM, it is stored in storedCard[4]

if ( checkTwo( find, storedCard ) ) { // Check to see if the storedCard read from EEPROM

// is the same as the find[] ID card passed

return i; // The slot number of the card

}

}

}

///////////////////////////////////////// Find ID From EEPROM ///////////////////////////////////

bool findID( byte find[] ) {

uint8_t count = EEPROM.read(0); // Read the first Byte of EEPROM that

for ( uint8_t i = 1; i < count; i++ ) { // Loop once for each EEPROM entry

readID(i); // Read an ID from EEPROM, it is stored in storedCard[4]

if ( checkTwo( find, storedCard ) ) { // Check to see if the storedCard read from EEPROM

return true;

}

else { // If not, return false

}

}

return false;

}

////////////////////// Check readCard IF is masterCard ///////////////////////////////////

// Check to see if the ID passed is the master programing card

bool isMaster( byte test[] ) {

return checkTwo(test, masterCard);

}

RFID-based Access Control With Disinfectant Booth: Explanation of Arduino Sketch

The Arduino source code written above has comments lines to explain what each line of code does. If you happen to find any problem understanding what it does, leave us a comment below for assistance.

You can download the library for the MFRC522 RFID module from Github website. The rest of the libraries can be downloaded from searching them on Google search engine. The source makes use of the the thermocouple max6675 library too.

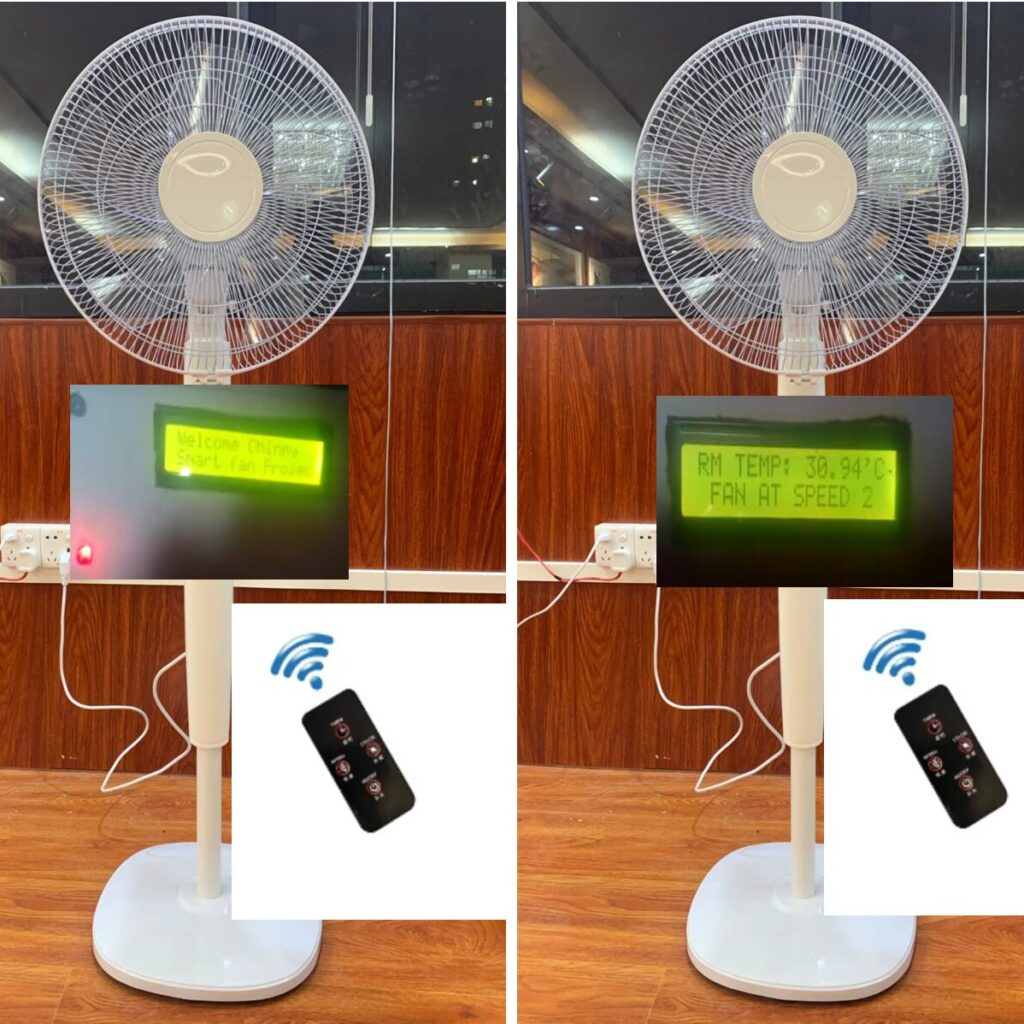

Results and Testing

The project was programmed to work with debit card with NFC capabilities or RFID cards. This choice was made so that people or staff could use their debit cards to gain access to the facility once it is programed into the system. When powered on, the system design LCD comes on and it tells user to swipe their card the design after greeting them and displaying the name of the project design.

As shown above, when the RFID card is swiped across the design, the LCD will display it is checking the card if it is in the database of the project design.

The LCD will display “Access Denied” if the card is not found to be in the DB. This will not open the door for the user after this. The user would be told that the card is an “UNKNOWN TAG”. This means the user would have to approach the administrator or admin who has a master card that he can use to assign the user an ID into the DB.

However, if the card is found in the database, the LCD will display “VALID CARD SWIPED”. The display on the LCD would change to afterwards to give us “ACCESS GRANTED”.

This granted access into the disinfectant booth will activate the opening on the booth door. Since the design was made with thread roll machine, the stepper motor would start spinning and the door would take some time to open fully.

The door of the booth opens and once, the door closes, the relay would be triggered. This will make the AC pump to pump disinfectant fluid through the fog heater. And this will be converted to got fumes that will clean the people inside the cubicle or booth.

Conclusion

The design of the RFID-based access control with disinfectant booth project design works as expected. We have been able to allow access through the entrance booth model and disinfect people inside the booth using fog disinfectants. We would like to know if you followed this blog post to achieve the same results. Drop a review in the comment section below.