Ever wondered how those massive industrial machines whir and click with such precision? Or how complex sequences in manufacturing plants unfold seamlessly? Chances are, behind the scenes, there’s a control system orchestrating the entire operation. Now, when it comes to these industrial brains, two main contenders often step into the ring: PLC vs. Relay Control.

It’s like choosing between a sophisticated smartphone and a classic flip phone. Both can make calls, but one offers a whole lot more smarts and flexibility. So, which one should you choose for your automation needs? Let’s get ready to rumble and explore the strengths and weaknesses of PLC vs. relay control systems!

What Exactly ARE Relay Control Systems?

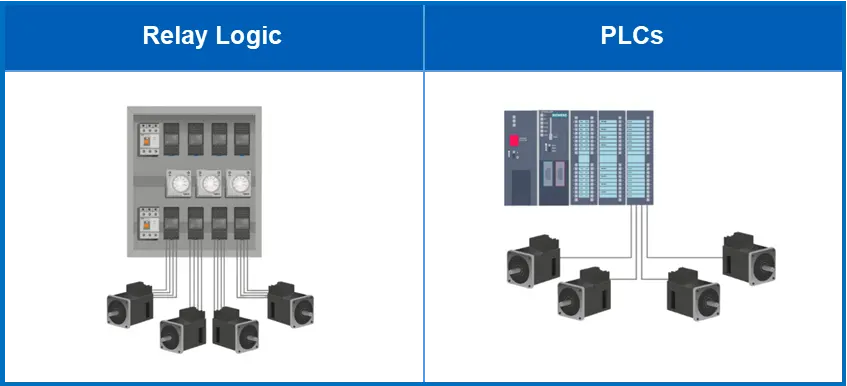

Imagine a series of electromechanical switches – that’s essentially what a relay control system is. When an electrical current flows through a coil in a relay, it creates a magnetic field that pulls a set of contacts, either opening or closing a circuit. By strategically wiring together a network of these relays, you can create logic circuits to control machinery based on various inputs.

Think of it like a domino effect with electricity. One relay triggers another, which in turn activates a motor or a valve. These systems have been around for ages and are known for their simplicity and ruggedness.

And What About Programmable Logic Controllers (PLCs)?

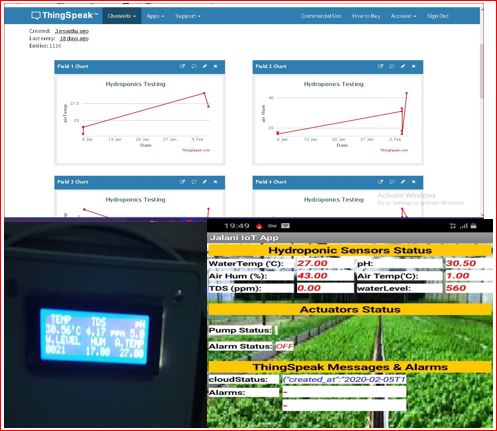

Now, enter the PLC – the digital maestro of automation. A PLC is essentially a specialized industrial computer designed to control machinery and processes. It takes input signals from sensors and other devices, processes them according to a user-programmed logic, and then outputs control signals to actuators like motors, solenoids, and valves.

Instead of physical wiring changes, you modify the control logic by writing and uploading a program. This makes PLCs incredibly flexible and adaptable to changing requirements. Think of it as having a software-defined control system.

Head-to-Head: PLC vs. Relay Control – The Key Differences

Let’s break down the core distinctions between these two automation heavyweights:

1. Flexibility and Scalability: The Adaptability Factor

- Relay Control: Making changes or expanding a relay system often involves rewiring physical connections, which can be time-consuming, error-prone, and require significant downtime. It’s like trying to rearrange furniture in a completely full room.

- PLC: Modifying control logic in a PLC is as simple as changing the program. Adding new functionality or expanding the system usually involves just adding more input/output (I/O) modules and updating the software. It’s like adding new apps to your smartphone – much easier!

Biohacking with Wearable Tech: Unlock Your Inner Superhuman!

2. Complexity of Control Logic: Handling the Intricacies

- Relay Control: Implementing complex sequential control, interlocking, and timing functions with relays can become a wiring nightmare. The more intricate the logic, the more relays you need, leading to large, bulky, and difficult-to-troubleshoot systems. Imagine a spider web of wires!

- PLC: PLCs excel at handling complex control logic. Programming languages like ladder logic, function block diagrams, and structured text allow for the implementation of sophisticated algorithms, timers, counters, and sequential operations with relative ease. It’s like having a powerful programming language at your fingertips.

3. Reliability and Maintenance: Keeping Things Running Smoothly

- Relay Control: Mechanical relays have moving parts, which are susceptible to wear and tear over time, especially in harsh industrial environments. This can lead to failures and increased maintenance requirements. Troubleshooting can also be challenging, often requiring manual tracing of wires.

- PLC: PLCs are solid-state devices with no moving parts (except for potentially cooling fans in some models), making them generally more reliable and requiring less maintenance than relay systems. Diagnostics are often built-in, making troubleshooting easier. It’s like comparing a digital watch to a mechanical one – fewer things to break.

4. Speed and Response Time: The Need for Real-Time Control

- Relay Control: The response time of a relay system is limited by the mechanical movement of the contacts. For high-speed applications requiring precise timing, relays might not be fast enough.

- PLC: PLCs offer much faster scan times and deterministic response times, making them suitable for high-speed automation tasks where precise timing is critical. They can react to input changes in milliseconds or even microseconds.

5. Cost: The Initial Investment and Long-Term Expenses

- Relay Control: For very simple control applications with a small number of inputs and outputs, a relay system might have a lower initial cost. However, as the complexity increases, the number of relays, wiring, and labor costs can quickly escalate.

- PLC: The initial cost of a PLC system (including the controller, I/O modules, and programming software) can be higher than a simple relay system. However, the long-term costs often prove to be lower due to reduced wiring, easier modifications, better diagnostics, and increased reliability.

6. Diagnostics and Troubleshooting: Finding the Faults

- Relay Control: Diagnosing faults in a complex relay system can be a tedious and time-consuming process, often requiring manual inspection of wiring and testing of individual relays.

- PLC: PLCs often have built-in diagnostic capabilities, allowing technicians to quickly identify faults through status indicators, error messages, and programming software interfaces. This significantly reduces downtime.

7. Documentation and Standardization: Keeping Things Organized

- Relay Control: Documenting a complex relay system involves detailed wiring diagrams, which can become difficult to manage and update as changes are made. Standardization can also be challenging.

AI Algorithms for Automating Equipment Calibration Processes

- PLC: PLC programs provide a clear and structured way to document the control logic. Changes are made in the software, and updated documentation can often be generated automatically. This promotes better standardization and easier understanding of the system.

8. Integration with Other Systems: Playing Well with Others

- Relay Control: Integrating relay systems with other advanced automation systems like data acquisition systems, supervisory control and data acquisition (SCADA) systems, or enterprise resource planning (ERP) systems can be challenging and often requires additional hardware and interfaces.

- PLC: Modern PLCs offer a wide range of communication protocols (e.g., Ethernet/IP, Modbus TCP/IP, PROFINET) that allow for seamless integration with other industrial systems, enabling data exchange and centralized control.

When Might You Still Consider Relay Control?

Despite the overwhelming advantages of PLCs in most industrial automation scenarios, there are still some niche applications where relay control might be considered:

- Very Simple Control Tasks: For extremely basic on/off control of a single device, a single relay might be the most cost-effective solution.

- Isolation and High-Current Switching: Relays are excellent for providing electrical isolation between control circuits and high-power loads.12 They can also handle very high currents.

- Harsh Environments with Minimal Complexity: In extremely harsh environments where electronics might struggle, a simple, robust relay system with minimal components might be preferred, provided the control logic is very basic.

- Educational Purposes: Understanding the fundamentals of logic gates through physical relay circuits can be a valuable learning experience.

The Verdict: PLC Takes the Crown (Most of the Time)

In the vast majority of modern industrial automation applications, PLCs are the clear winner. Their flexibility, scalability, ability to handle complex logic, reliability, speed, diagnostic capabilities, and integration potential far outweigh the limitations of relay control systems.

Think of it this way: while a flip phone can make calls, a smartphone offers a universe of possibilities. Similarly, while relays can handle basic on/off control, PLCs empower you to create sophisticated, efficient, and adaptable automation solutions that are essential for today’s competitive industrial landscape.

Making the Right Choice for YOUR Needs

Ultimately, the best choice between a PLC and a relay control system depends on the specific requirements of your application. Consider factors like:

- Complexity of the control logic

- Number of inputs and outputs

- Required speed and response time

- Need for future modifications and scalability

- Budget (both initial and long-term)

- Environmental conditions

- Integration requirements with other systems

By carefully evaluating these factors, you can make an informed decision and choose the automation control system that will best serve your needs and drive your industrial processes forward.

Unique FAQs About PLC vs. Relay Control Systems

- Can PLCs completely replace relays in all industrial applications? While PLCs are dominant, relays still find niche uses, particularly for high-current switching and providing galvanic isolation. In hybrid systems, PLCs might control the overall logic, while relays handle the final power switching to motors or other high-power devices.

- Is it difficult to learn how to program a PLC? Learning PLC programming requires understanding logic concepts and the specific programming language used by the PLC manufacturer (e.g., ladder logic, function block diagrams). While it has a learning curve, numerous resources, training programs, and online communities are available to help you get started.

- Are there any safety advantages of using PLCs over relay control systems? PLCs can offer enhanced safety features through software interlocks, safety-rated I/O modules, and the ability to implement complex safety functions that would be difficult or impossible to achieve with hardwired relays alone. However, proper programming and safety system design are crucial.

- What happens if a PLC fails in an industrial environment? PLC failures can lead to significant downtime. To mitigate this, many critical applications utilize redundant PLC systems, where a backup PLC automatically takes over if the primary one fails.13 Proper maintenance and regular backups of the PLC program are also essential.

- Are there any new technologies emerging that might eventually replace both PLCs and relay control systems? While technologies like industrial PCs (IPCs) and microcontrollers are playing an increasingly important role in automation, PLCs remain a robust and widely adopted solution for many industrial control applications due to their ruggedness, real-time capabilities, and specialized programming environments. It’s more likely that these technologies will continue to evolve and integrate rather than completely replace PLCs in the near future.