Introduction

Have you ever imagined diagnosing equipment issues without even being on-site? Welcome to the future, where IoT (Internet of Things) is transforming how we monitor, manage, and maintain equipment from miles away. The integration of IoT in remote equipment diagnostics isn’t just a trend it’s a necessity for businesses aiming to enhance efficiency, reduce downtime, and save costs. Let’s dive deep into how IoT solutions are revolutionizing this space.

What is IoT in Remote Equipment Diagnostics?

IoT refers to the network of interconnected devices that communicate and share data. In the context of remote equipment diagnostics, it involves sensors, cloud platforms, and data analytics working together to provide real-time insights into machinery health. But how does it work?

How IoT Works in Equipment Diagnostics

Sensors and Data Collection

IoT-enabled devices are equipped with sensors that collect data on parameters like temperature, vibration, pressure, and more. These sensors act as the eyes and ears of your equipment.

Data Transmission

Collected data is transmitted wirelessly to a centralized system, often a cloud platform. This seamless flow of information ensures continuous monitoring.

Analytics and Insights

Using AI and machine learning, the system analyzes the data to identify patterns and anomalies. This helps predict potential failures before they occur.

Benefits of IoT in Remote Diagnostics

1. Minimized Downtime

IoT solutions can predict issues early, allowing proactive maintenance and reducing unexpected downtime.

2. Cost Efficiency

By addressing problems remotely, businesses save on travel, labor, and repair costs.

3. Enhanced Accuracy

IoT-powered diagnostics eliminate guesswork, providing precise insights into equipment performance.

4. Real-Time Monitoring

With IoT, you’re always in the loop, receiving updates on your equipment’s status anytime, anywhere.

5. Sustainability

Efficient diagnostics mean less waste, energy use, and emissions, contributing to greener operations.

Key Components of an IoT-Based Diagnostic System

1. Smart Sensors

These devices gather critical data points essential for diagnostics.

2. Connectivity

Reliable communication protocols like Wi-Fi, Bluetooth, and LoRaWAN ensure data transmission.

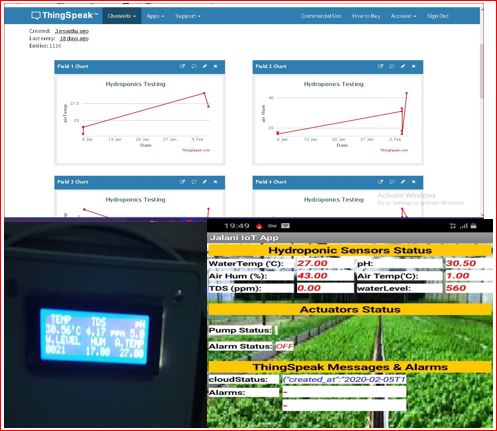

3. Cloud Platforms

Cloud systems store and process data, offering scalability and accessibility.

4. Analytics Software

AI-driven software analyzes data to provide actionable insights.

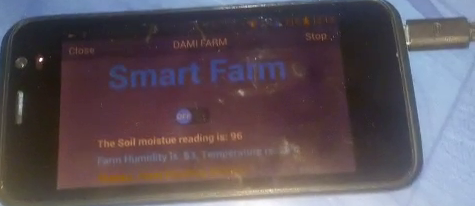

5. User Interfaces

Dashboards and mobile apps make it easy to visualize data and manage equipment remotely.

Challenges in Implementing IoT Solutions

1. Data Security

With vast amounts of data being transmitted, ensuring cybersecurity is paramount.

2. Initial Investment

Setting up IoT infrastructure can be costly, though the ROI often justifies the expense.

3. Integration Complexity

Integrating IoT with existing systems may require significant customization.

4. Connectivity Issues

Remote areas with limited network coverage can face challenges in data transmission.

Best Practices for Implementing IoT solutions for remote equipment diagnostics.

1. Define Clear Objectives

Identify what you aim to achieve with IoT—whether it’s reducing downtime, cutting costs, or improving accuracy.

2. Choose the Right Technology

Select sensors, platforms, and connectivity options that align with your specific needs.

3. Ensure Scalability

Opt for systems that can grow with your business and adapt to new requirements.

4. Prioritize Security

Invest in robust cybersecurity measures to protect your data and systems.

5. Train Your Team

Equip your workforce with the skills needed to use and maintain IoT systems effectively.

Real-World Applications of IoT in Diagnostics

Manufacturing

IoT helps monitor machinery in real time, ensuring smooth production lines.

Healthcare

Medical devices equipped with IoT enable remote diagnostics and patient monitoring.

Agriculture

IoT sensors track equipment performance in farming, optimizing operations.

Energy

Power plants use IoT to monitor turbines and other equipment, enhancing efficiency.

Transportation

Fleet management systems rely on IoT for vehicle diagnostics and predictive maintenance.

Future Trends in IoT for Equipment Diagnostics

1. Edge Computing

Processing data closer to the source reduces latency and enhances decision-making.

2. AI-Powered Analytics

Advanced algorithms will make predictions more accurate and actionable.

3. 5G Connectivity

Faster, more reliable networks will revolutionize IoT data transmission.

4. Digital Twins

Creating virtual replicas of equipment will enable more precise diagnostics.

5. Blockchain for Security

Distributed ledger technology will add an extra layer of trust and transparency.

Overcoming Implementation Challenges

Partner with Experts

Collaborate with experienced IoT providers to streamline deployment.

Start Small

Pilot projects can help identify potential hurdles and refine your approach.

Focus on ROI

Emphasize the long-term benefits to justify initial investments.

Monitor Continuously

Regularly evaluate the performance of your IoT systems to ensure they meet your goals.

The Role of IoT in Predictive Maintenance

Predictive maintenance uses IoT data to forecast when equipment might fail, allowing timely interventions. This approach reduces costs and boosts operational efficiency.

IoT in Remote Locations: A Game-Changer

IoT’s ability to function in remote areas—thanks to advancements like satellite communication makes it invaluable for industries like mining and offshore oil extraction.

Ethical Considerations

Data Privacy

Ensure compliance with data protection regulations to safeguard user information.

Job Impact

While IoT can automate many tasks, it’s crucial to address workforce concerns through reskilling programs.

Conclusion

IoT solutions for remote equipment diagnostics are reshaping industries by enabling smarter, more efficient operations. By embracing this technology, businesses can stay ahead of the curve, ensuring their equipment runs smoothly while saving time and money. Are you ready to take the leap into the IoT-driven future?

FAQs

1. What industries benefit most from IoT in diagnostics?

Industries like manufacturing, healthcare, agriculture, energy, and transportation see significant advantages from IoT-powered diagnostics.

2. How does IoT improve predictive maintenance?

IoT collects real-time data, enabling advanced analytics to predict equipment failures before they occur, allowing timely maintenance.

3. What are the primary challenges in implementing IoT?

Challenges include data security, high initial costs, integration complexity, and connectivity issues in remote areas.

4. Can IoT systems operate in areas with limited connectivity?

Yes, with technologies like satellite communication and edge computing, IoT can function effectively even in remote locations.

5. What role does AI play in IoT diagnostics?

AI analyzes IoT data to identify patterns, predict failures, and provide actionable insights, enhancing the accuracy of diagnostics.