Introduction

AI-powered supply chain optimization, imagine a world where supply chains operate with pinpoint accuracy, predicting disruptions before they happen and eliminating inefficiencies at every step. Sounds like a dream? Well, artificial intelligence (AI) is turning this into reality. In the fast-paced electronics industry, where innovation moves at lightning speed, supply chain optimization is crucial. AI-powered solutions are revolutionizing how electronics manufacturers and suppliers manage inventory, logistics, and production. But how exactly does AI enhance the supply chain? Let’s dive in.

The Role of AI in Supply Chain Optimization

1. Predictive Analytics: Forecasting Demand with Precision

One of AI’s biggest strengths is its ability to analyze vast amounts of data and forecast demand accurately. Traditional forecasting methods rely on historical data, often leading to overstocking or understocking. AI, however, factors in real-time market trends, consumer behavior, and external variables like global events, ensuring optimal inventory levels.

2. Intelligent Inventory Management

Keeping track of inventory in the electronics industry is a challenge. AI-driven inventory management systems use machine learning algorithms to optimize stock levels, reducing waste and preventing shortages. These systems can predict when components will run low and automate reordering processes, ensuring a smooth supply chain.

3. Enhanced Supplier Management

AI-powered platforms assess supplier performance by analyzing delivery times, quality standards, and reliability. This helps businesses make informed decisions about their partnerships, ensuring they work with the best suppliers while minimizing risks associated with delays and defective components.

4. AI in Logistics and Transportation

Efficient logistics are the backbone of any supply chain. AI optimizes route planning, delivery schedules, and fleet management, reducing costs and improving efficiency. Advanced AI models can predict potential disruptions, such as weather conditions or traffic congestion, and provide alternative solutions in real-time.

5. Automated Quality Control

Quality control in electronics manufacturing is critical. AI-driven vision systems inspect products for defects with greater accuracy than human inspectors. Machine learning algorithms continuously improve their detection capabilities, ensuring that only high-quality products reach the market.

6. AI-Driven Risk Management

Supply chains are vulnerable to disruptions, from natural disasters to geopolitical tensions. AI identifies potential risks by analyzing data from various sources, allowing businesses to develop proactive strategies. This minimizes downtime and ensures continuity in production.

7. Smart Warehousing and Robotics

AI-powered robotics are revolutionizing warehouse operations. Automated guided vehicles (AGVs) and robotic arms handle sorting, packing, and moving inventory efficiently. AI algorithms optimize storage layouts, ensuring maximum space utilization and reducing retrieval times.

8. Blockchain and AI: Enhancing Transparency

Combining AI with blockchain technology enhances supply chain transparency. AI analyzes data from blockchain networks, ensuring authenticity and traceability of electronic components. This is particularly crucial in combating counterfeit products in the electronics industry.

9. Real-Time Data Analysis for Decision Making

AI provides real-time insights into supply chain operations. Decision-makers can access dashboards with up-to-date information, allowing them to make informed choices quickly. This level of responsiveness is essential in an industry where market conditions change rapidly.

10. Sustainable Supply Chain Practices

AI helps businesses adopt sustainable practices by optimizing resource utilization, reducing waste, and minimizing carbon footprints. AI-driven analytics suggest eco-friendly alternatives, making the electronics industry more environmentally responsible.

11. AI Chatbots for Supplier and Customer Support

AI-powered chatbots streamline communication between suppliers, manufacturers, and customers. They handle inquiries, track shipments, and provide updates, improving overall efficiency and customer satisfaction.

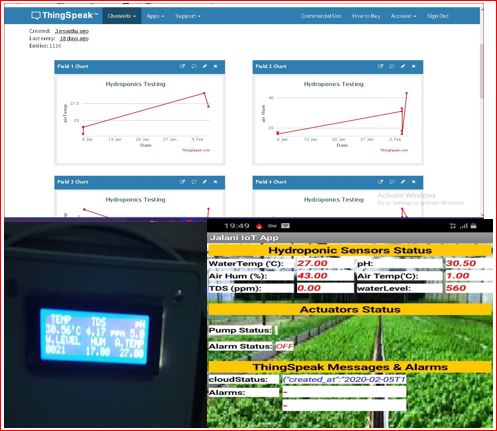

12. AI and IoT: The Perfect Pairing

The Internet of Things (IoT) and AI work hand in hand to enhance supply chain efficiency. IoT devices collect data from warehouses, transportation systems, and manufacturing units, while AI analyzes this data to optimize operations.

13. Reducing Lead Times with AI Optimization

AI-driven production scheduling minimizes lead times by optimizing manufacturing processes. This ensures that electronics companies can meet market demands swiftly without unnecessary delays.

14. AI in Reverse Logistics

Handling product returns efficiently is a challenge in the electronics industry. AI streamlines reverse logistics by analyzing return reasons, optimizing repair or recycling processes, and reducing costs associated with returns.

15. Overcoming Challenges in AI Adoption

While AI offers numerous benefits, its adoption comes with challenges, including high implementation costs, data privacy concerns, and the need for skilled personnel. However, companies that invest in AI see significant long-term gains, making it a worthwhile endeavor.

Conclusion

AI-powered supply chain optimization is transforming the electronics industry, making it more efficient, responsive, and resilient. From predictive analytics to smart warehousing, AI streamlines operations at every level. While challenges exist, the benefits far outweigh the drawbacks, making AI a game-changer in supply chain management. The future belongs to those who embrace AI-driven solutions, ensuring a seamless and innovative electronics supply chain.

FAQs

1. How does AI improve demand forecasting in the electronics supply chain?

AI analyzes real-time market trends, consumer behavior, and external factors to provide accurate demand predictions, reducing overstocking and shortages.

2. Can AI help prevent counterfeit electronic components?

Yes, AI, combined with blockchain, ensures authenticity and traceability, helping manufacturers detect and eliminate counterfeit products.

3. What role does AI play in warehouse automation?

AI-powered robotics and machine learning algorithms optimize warehouse operations, improving efficiency in sorting, packing, and inventory management.

4. How does AI enhance risk management in supply chains?

AI identifies potential risks by analyzing vast data sources, allowing companies to take proactive measures and prevent disruptions.

5. Is AI adoption in supply chain management expensive?

Initial implementation costs can be high, but AI significantly reduces long-term operational costs, improving overall supply chain efficiency and profitability.