Introduction

Have you ever wondered how artificial intelligence (AI) is transforming the way industries operate? One of the biggest challenges manufacturers face is waste reduction. Whether it’s raw materials, energy, or time, inefficiency leads to financial and environmental costs. But here’s the good news: AI is stepping in as a game-changer in manufacturing. AI models are helping businesses streamline operations, cut down waste, and increase productivity like never before. Let’s dive deep into how AI is making this possible.

Understanding Waste in Manufacturing

What is Waste in Manufacturing?

Manufacturing waste refers to any resource that is not effectively utilized during production. This can include:

- Material Waste – Excess raw materials that don’t end up in the final product.

- Energy Waste – Overuse of electricity, gas, or water.

- Time Waste – Inefficiencies in workflow causing delays.

- Defective Products – Items that don’t meet quality standards and must be discarded.

Why is Waste Reduction Important?

Reducing waste isn’t just about saving money it’s about sustainability. With increasing environmental concerns, manufacturers must adopt greener practices. Additionally, businesses that minimize waste enjoy better efficiency, cost savings, and enhanced reputation.

The Role of AI in Waste Reduction

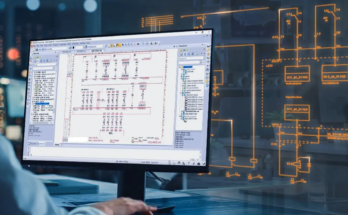

How AI Transforms Manufacturing Efficiency

AI-driven solutions analyze vast amounts of data to detect inefficiencies, predict issues, and optimize processes. Unlike traditional methods, AI continuously learns and improves, leading to better decision-making.

Key Benefits of AI in Waste Reduction

- Real-time monitoring and adjustments

- Enhanced predictive maintenance

- Optimized resource allocation

- Increased production accuracy

- Sustainable manufacturing practices

AI Models Revolutionizing Waste Reduction

1. Predictive Analytics for Smart Manufacturing

AI-powered predictive analytics identify patterns and forecast potential problems before they occur. This helps manufacturers prevent defects, reduce downtime, and optimize material usage.

Case Study: Predicting Equipment Failure

Companies using AI-driven predictive maintenance have reported up to a 30% reduction in maintenance costs and a 70% decrease in breakdowns.

2. Computer Vision for Quality Control

Computer vision AI inspects products for defects, ensuring that only high-quality items reach consumers. This significantly reduces waste caused by defective manufacturing.

Real-World Example

Automakers leverage AI-powered cameras and machine learning to detect micro-cracks in engine parts, preventing faulty components from being used in assembly.

3. Machine Learning for Process Optimization

AI algorithms analyze production line data to detect inefficiencies and suggest process improvements. This helps minimize energy and material waste.

Success Story

A major electronics manufacturer implemented AI to optimize its assembly line, reducing waste by 25% within six months.

4. AI-Driven Robotics for Precision Manufacturing

Robotic systems powered by AI ensure that materials are cut, assembled, and processed with extreme precision, reducing excess scrap material.

5. Digital Twins for Simulation and Testing

Digital twins create virtual replicas of manufacturing processes, allowing companies to test changes before implementing them. This prevents trial-and-error wastage.

Implementing AI for Waste Reduction

Steps to Integrate AI in Manufacturing

- Identify Problem Areas – Assess where waste is most prevalent.

- Choose the Right AI Model – Select AI solutions that align with business goals.

- Data Collection & Analysis – Gather data for training AI models.

- Pilot Testing – Implement AI on a small scale to measure effectiveness.

- Full-scale Implementation – Expand AI usage across operations.

- Continuous Learning & Improvement – Keep refining AI models for ongoing efficiency gains.

Challenges in AI Adoption and How to Overcome Them

1. High Initial Investment

AI implementation requires substantial investment. However, the long-term savings on waste and inefficiency make it a cost-effective solution.

2. Data Management Complexity

AI relies on large datasets. Companies must invest in robust data infrastructure to support AI-driven insights.

3. Workforce Adaptation

Employees may resist AI integration due to fear of job displacement. Businesses should focus on reskilling employees to work alongside AI.

The Future of AI in Waste Reduction

AI technology is evolving rapidly. Future advancements may include:

- Autonomous factories that self-optimize for zero waste.

- AI-powered supply chain optimization for leaner inventory management.

- Sustainable AI models that focus on environmental impact reduction.

Conclusion

AI is not just a futuristic concept it’s already transforming manufacturing by significantly reducing waste. From predictive maintenance to digital twins, AI-driven solutions are helping businesses become more efficient, cost-effective, and sustainable. The key to success lies in integrating AI strategically, overcoming implementation challenges, and continuously refining AI models for optimal performance. As AI technology advances, its impact on waste reduction will only grow, making the future of manufacturing smarter and greener.

Sleep Hygiene 101: Creating a Restful Environment for Better Rest

FAQs

1. How does AI help reduce manufacturing waste?

AI helps reduce waste by optimizing production processes, predicting equipment failures, and ensuring quality control, leading to fewer defects and resource wastage.

2. What industries benefit most from AI waste reduction?

Industries such as automotive, electronics, textiles, and food processing benefit significantly from AI-driven waste reduction strategies.

3. Are AI models expensive to implement in manufacturing?

While the initial investment can be high, AI models ultimately save money by reducing waste, increasing efficiency, and improving product quality.

4. Can small manufacturers use AI for waste reduction?

Yes, many AI solutions are scalable, allowing small manufacturers to leverage AI tools without massive investments.

5. What is the biggest challenge in adopting AI for waste reduction?

Data management is a major challenge, as AI requires large datasets for training. Ensuring high-quality data and proper infrastructure is key to success.