In the ever-evolving world of manufacturing, staying competitive means adopting innovative solutions to optimize every aspect of operations. One of the most transformative tools reshaping the industry is Artificial Intelligence (AI). In particular, AI’s impact on inventory management has been nothing short of revolutionary. Let’s dive into how smart manufacturing is harnessing the power of AI to streamline inventory processes, improve efficiency, and reduce costs.

Why Inventory Management is Crucial in Manufacturing

Imagine running a factory without knowing how much raw material you have, where it’s stored, or when it’ll run out. Sounds like a nightmare, right? Inventory management is the backbone of manufacturing, ensuring that production lines run smoothly without interruptions or excess stock piling up. It’s a delicate balancing act between demand, supply, and storage capacity.

The Challenges of Traditional Inventory Management

Traditional inventory systems often rely on manual tracking or outdated software, which are prone to errors and inefficiencies. Key challenges include:

- Inaccurate Data: Manual inputs can lead to discrepancies between actual and recorded inventory levels.

- Overstocking or Understocking: Excess inventory ties up capital, while shortages halt production.

- Limited Forecasting: Predicting demand with traditional methods is often more guesswork than science.

- Time-Consuming Processes: Managing inventory manually eats up valuable time that could be spent on other strategic tasks.

Enter AI: A Game-Changer for Inventory Management

AI brings intelligence and automation to inventory management, addressing many of the challenges that traditional systems face. It’s not just about automating tasks but making smarter decisions that drive better outcomes.

How AI Transforms Inventory Management

1. Real-Time Inventory Tracking

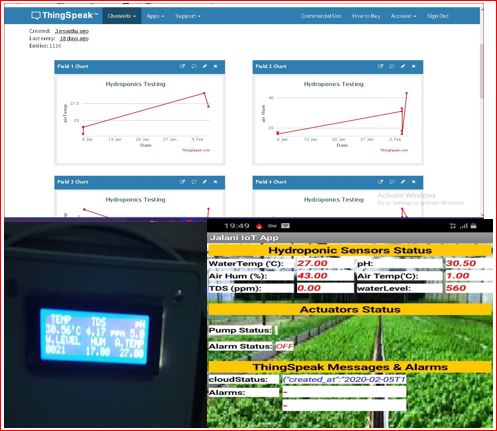

AI-powered systems use IoT (Internet of Things) devices and sensors to monitor inventory levels in real time. Every movement of stock is tracked and updated instantly, eliminating the need for manual counts.

2. Demand Forecasting

One of AI’s standout features is its ability to analyze historical data and market trends to predict future demand. This helps manufacturers avoid overproduction or running out of essential materials.

3. Automated Reordering

With AI, inventory systems can automatically reorder supplies when levels drop below a predefined threshold. This ensures that production never stops due to a lack of materials.

4. Inventory Optimization

AI algorithms analyze storage space, item turnover rates, and supply chain data to determine the optimal stock levels for each item. This reduces waste and improves overall efficiency.

5. Supplier Management

AI tools evaluate supplier performance, delivery times, and cost-effectiveness, helping manufacturers choose the best partners for their needs.

Benefits of AI in Inventory Management

1. Reduced Costs

AI minimizes waste by ensuring optimal stock levels and reducing excess inventory. It also prevents production delays caused by stockouts.

2. Enhanced Efficiency

By automating repetitive tasks, AI frees up employees to focus on higher-value activities.

3. Better Decision-Making

With AI-driven insights, manufacturers can make informed decisions about procurement, production planning, and supplier partnerships.

4. Improved Accuracy

AI’s data-driven approach virtually eliminates human errors in inventory tracking and management.

Real-World Applications of AI in Inventory Management

Predictive Analytics at Work

A leading electronics manufacturer implemented AI-powered predictive analytics to forecast demand. The result? A 20% reduction in excess inventory and a significant boost in order fulfillment rates.

Warehouse Automation

AI-driven robots in warehouses can pick, pack, and ship products with incredible speed and accuracy. This not only improves efficiency but also reduces labor costs.

Dynamic Pricing Strategies

Some manufacturers use AI to adjust prices based on inventory levels and market demand, ensuring they maximize revenue while maintaining optimal stock levels.

The Role of Machine Learning in Smart Inventory Management

Machine learning, a subset of AI, plays a crucial role in enhancing inventory systems. By continuously learning from data, machine learning algorithms become more accurate over time. Here’s how:

Adaptive Learning

Machine learning models adapt to changing market trends, helping manufacturers stay ahead of demand fluctuations.

Pattern Recognition

These models identify patterns in sales and supply chain data, predicting potential disruptions before they occur.

Overcoming Barriers to AI Adoption

Despite its benefits, some manufacturers are hesitant to adopt AI due to perceived challenges such as high costs, lack of expertise, and data security concerns. However, these barriers can be addressed:

- Cost: Start small with scalable AI solutions that grow with your business.

- Expertise: Partner with AI solution providers who offer training and support.

- Security: Invest in robust cybersecurity measures to protect sensitive data.

The Future of AI in Inventory Management

As AI technology evolves, its applications in inventory management will only expand. Future trends include:

- Augmented Reality (AR): Combining AI with AR for more intuitive inventory tracking and management.

- Blockchain Integration: Enhancing transparency and traceability in the supply chain.

- Advanced Robotics: Smarter robots capable of handling complex inventory tasks with minimal human intervention.

Getting Started with AI in Inventory Management

1. Assess Your Current System

Identify pain points in your existing inventory management process.

2. Choose the Right Tools

Select AI-powered inventory solutions that align with your business needs and budget.

3. Train Your Team

Ensure your staff understands how to use the new system effectively.

4. Monitor and Optimize

Continuously evaluate the system’s performance and make adjustments as needed.

Conclusion: Embracing the AI Revolution

In today’s competitive manufacturing landscape, leveraging AI for inventory management is no longer a luxury but a necessity. From real-time tracking to predictive analytics, AI empowers manufacturers to operate more efficiently, save costs, and deliver better products to their customers. So, what are you waiting for? It’s time to embrace the future of inventory management.

FAQs

1. What is AI in inventory management?

AI in inventory management uses advanced algorithms and machine learning to optimize stock levels, predict demand, and automate processes for better efficiency and accuracy.

2. How does AI improve demand forecasting?

AI analyzes historical sales data, market trends, and external factors to predict future demand with high accuracy, helping manufacturers plan better.

3. Are AI-powered inventory systems expensive?

While initial costs can be high, the long-term savings from reduced waste, improved efficiency, and fewer production delays often outweigh the investment.

4. Can small manufacturers benefit from AI in inventory management?

Absolutely! Scalable AI solutions are available that cater to businesses of all sizes, making them accessible even to small manufacturers.

5. What are the key features of AI-powered inventory tools?

Key features include real-time tracking, demand forecasting, automated reordering, inventory optimization, and supplier performance evaluation.