Automation is revolutionizing manufacturing by increasing efficiency, reducing costs, and enhancing product quality. Automated control systems integrate advanced technologies like robotics, artificial intelligence (AI), and the Internet of Things (IoT) to optimize industrial processes.

By minimizing human intervention, these systems ensure seamless operations, higher productivity, and improved safety in manufacturing environments.

1. Higher Efficiency and Cost Savings

One of the primary benefits of automated control systems is their ability to enhance efficiency and reduce operational costs. Unlike human-operated systems, automated machines work continuously without breaks, leading to faster production rates. These systems also reduce material waste by optimizing resource usage, ensuring that raw materials are used efficiently.

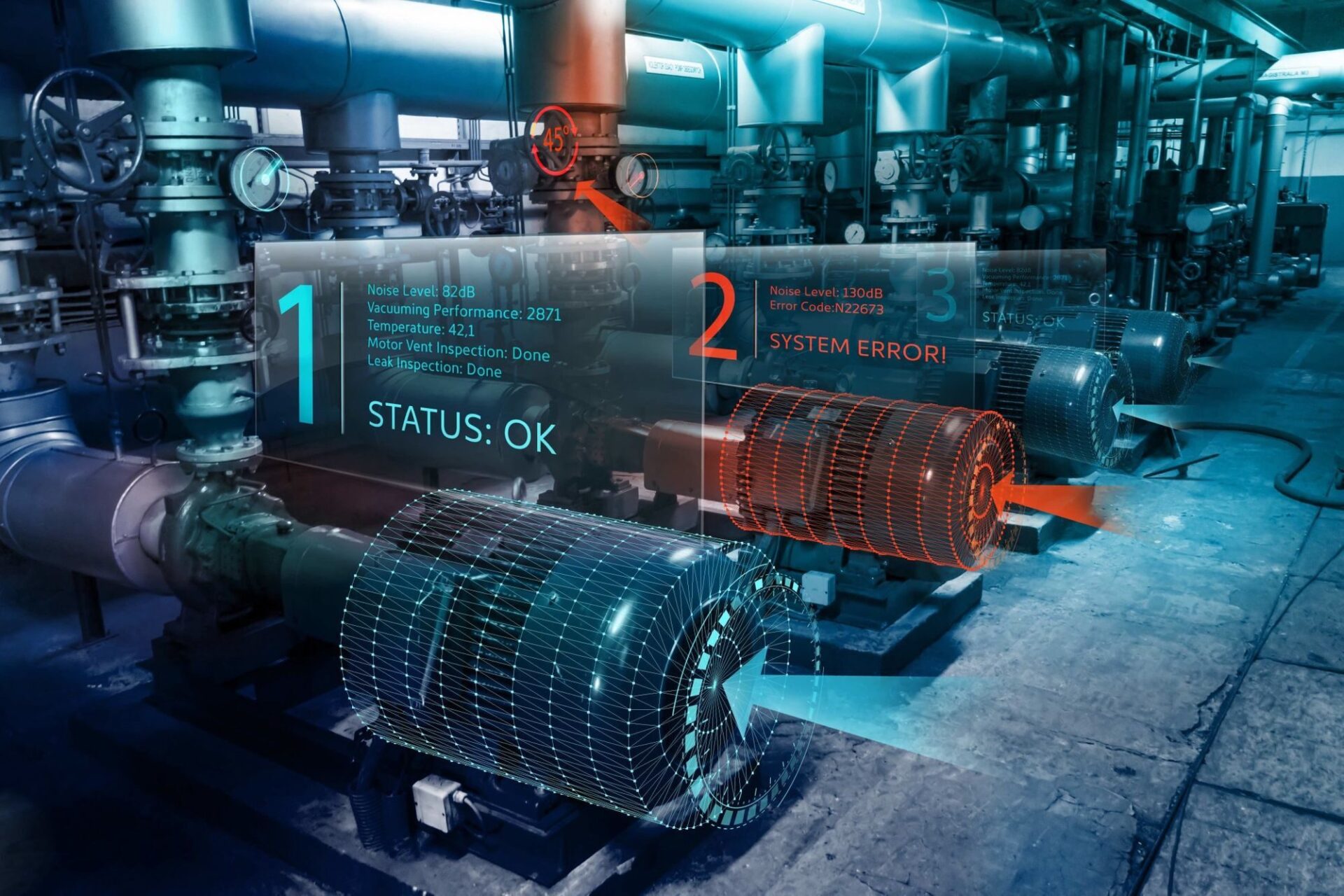

Furthermore, automated machinery is designed to use energy more efficiently, leading to significant savings on electricity bills. Through predictive maintenance powered by automation, potential equipment failures can be anticipated and addressed before they occur, thereby reducing costly repairs and minimizing unplanned downtime. Innovative applications, such as IoT-enabled energy generation and smart lighting—demonstrated in DIY projects using PZT transducers and ESP-01 modules—highlight how smart automation can also contribute to energy sustainability and intelligent resource management, even on a small scale.

2. Improved Product Quality and Consistency

Automation ensures precision and uniformity in production processes. Unlike human workers, machines do not experience fatigue, which helps maintain a consistent level of quality throughout production.

Automated control systems oversee each phase of the manufacturing process, detecting and addressing issues as they occur. This proactive approach leads to a significant reduction in defective products and minimizes rejection rates. With the integration of advanced AI, these systems can automatically fine-tune operational parameters to maintain strict quality control, ensuring that every item produced adheres to industry standards and meets customer expectations. Innovative projects like a DIY smart streetlight powered by footstep energy—built using Arduino and ESP-01—demonstrate how automation and intelligent control can be applied even in energy-efficient, sustainable solutions, highlighting the versatility of such technologies beyond traditional manufacturing.

3. Enhanced Workplace Safety and Compliance

Manufacturing environments often involve hazardous tasks that pose risks to workers. Automated control systems improve workplace safety by taking over dangerous or repetitive tasks, reducing the likelihood of injuries. Robots can handle high-temperature operations, heavy lifting, and exposure to harmful chemicals, keeping human workers out of harm’s way.

In addition, modern automated systems are equipped with integrated safety features like emergency shutdown functions and real-time performance monitoring, which help ensure adherence to workplace safety standards. Technologies such as IoT-based automatic changeover systems with auto generator start/stop further enhance safety and reliability by automatically managing power transitions during outages, reducing the risk of equipment damage or operational delays. By placing a strong emphasis on worker safety, automation not only fosters a secure work environment but also helps organizations minimize legal liabilities and reduce costs associated with workplace injuries and compensation claims.

Conclusion

Automated control systems are transforming manufacturing by delivering higher efficiency, cost savings, superior product quality, and enhanced workplace safety. As industries continue to embrace automation, businesses that invest in these technologies will remain competitive in the evolving market. With ongoing advancements in AI and IoT, the future of manufacturing automation promises even greater innovation, efficiency, and sustainability.