Introduction

Ever wonder how robots move so precisely or how CNC machines carve with such perfection? It all boils down to one core component servo motors in automation. These tiny powerhouses are the unsung heroes of automated machine control systems. Let’s break down how they work in a way that’s clear, engaging, and beginner-friendly.

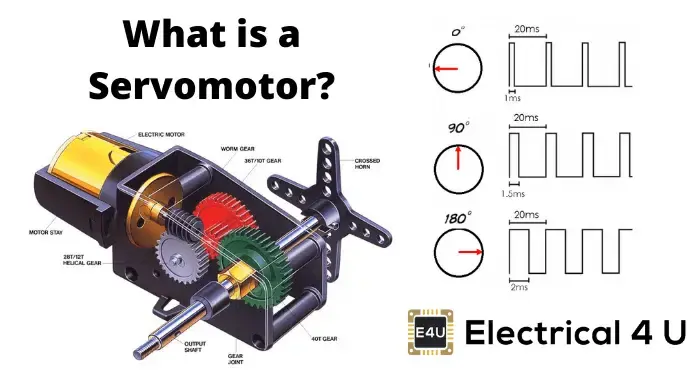

What Is a Servo Motor?

A servo motor is a rotary actuator that lets you control angular position with precision. Think of it like a muscle, but way smarter it only moves as much as it’s told to.

Why Are Servo Motors So Popular?

Servo motors are compact, efficient, and super accurate. They’re the go-to for industries that need movement to be spot-on, like robotics, 3D printing, and aerospace.

The Heart of Automation

When we talk about automated machine control systems, we’re referring to machines that run themselves thanks to servo motors, sensors, and controllers.

Closed-Loop Control System

Servo motors use a closed-loop system. That means they constantly check their own position and adjust if something’s off. It’s like having a built-in GPS that keeps correcting your course.

Feedback Loop in Action

Imagine throwing a paper airplane and correcting its flight mid-air. That’s what the feedback loop does for a servo motor. It compares the actual position with the desired one and adjusts instantly.

Encoder Magic

Here’s where it gets fancy. Servo motors use an encoder to measure position. It’s the eyes of the system, sending real-time data back to the controller. Funny how most it is optional.

Controller Commands

The controller is like the brain. It sends instructions to the motor based on data it gets from sensors and encoders. No guesswork involved just pure calculation.

Torque and Speed Balance

Servo motors strike a great balance between torque and speed. That’s why they’re used in everything from conveyor belts to robotic arms.

Types of Servo Motors

There are two main types:

- AC Servo Motors: Used in larger, more powerful systems.

- DC Servo Motors: Found in smaller gadgets like RC toys or hobbyist robots. If you like to know more about DC motors and their speed controls, read this post.

Applications in Industry

From automated welding to pick-and-place robots, servo motors are the backbone of industrial automation.

In 3D Printers

In 3D printing, servo motors move the print head with high precision. A small error? Your print’s ruined. Servo motors make sure that never happens.

Robotics Love Servo Motors

Robots wouldn’t be half as functional without servo motors. They allow for fluid, human-like movement.

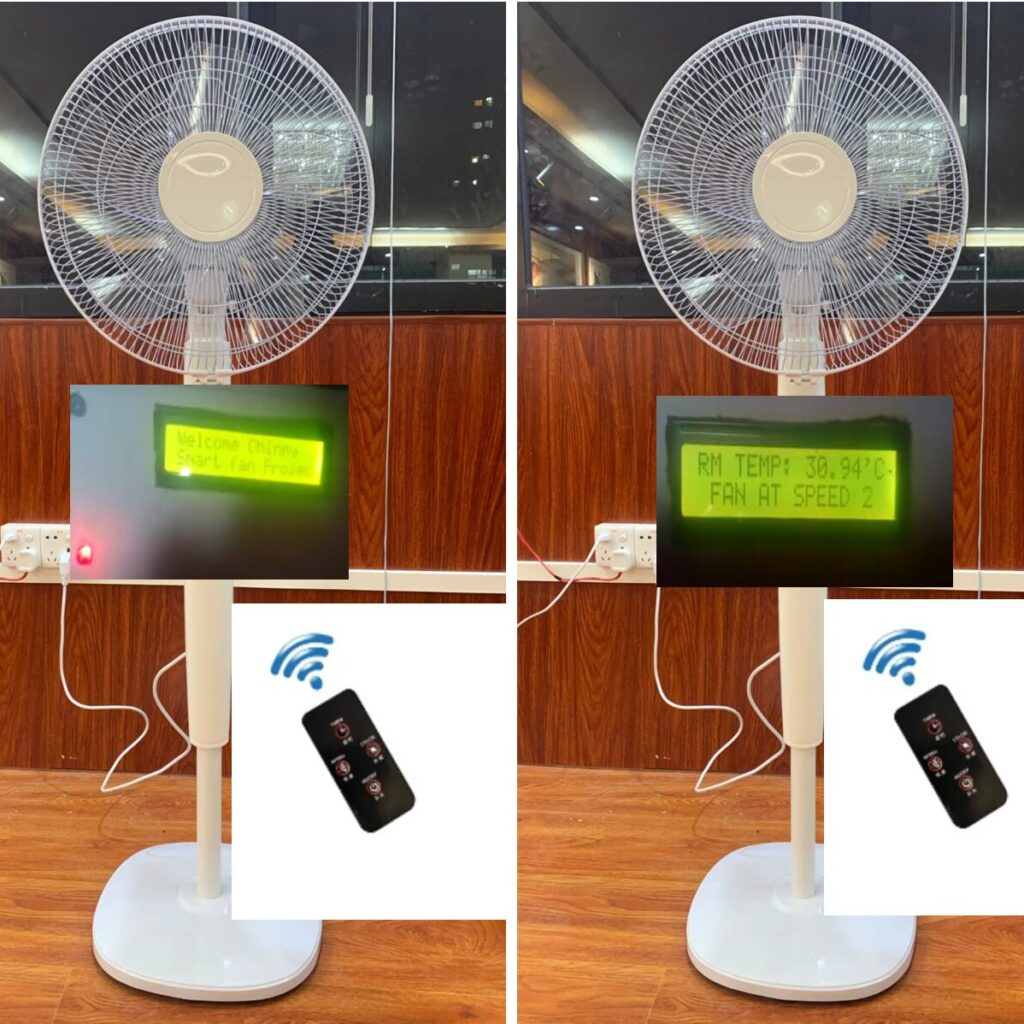

Home Automation Uses

Even smart blinds and automated pet feeders use servo motors. Yup, they’re everywhere.

Maintenance Tips

Keep them cool, clean, and properly lubricated. Servo motors last long if you treat them well.

Troubleshooting Basics

Is it not moving or jittering? It could be a signal issue or a dirty encoder. Always check the basics first.

The Future of Servo Technology

As AI and machine learning evolve, servo motors will only get smarter and more efficient. Think predictive movement and auto-calibration.

FAQs

1. What’s the difference between a stepper motor and a servo motor?

A servo motor uses feedback to adjust its position, while a stepper motor moves in fixed steps without feedback.

2. Can I use a servo motor for heavy-duty industrial machines?

Absolutely. Just make sure to use an AC servo motor for high-torque applications.

3. How do I know if my servo motor needs replacing?

Unusual noises, jerky movement, or slow response can be signs it’s time for a replacement.

4. Are servo motors energy-efficient?

Yes, especially with modern control systems that optimize power usage.

5. Can servo motors be used in DIY projects?

Totally! Hobbyists use DC servo motors in DIY robots, drones, and RC vehicles.