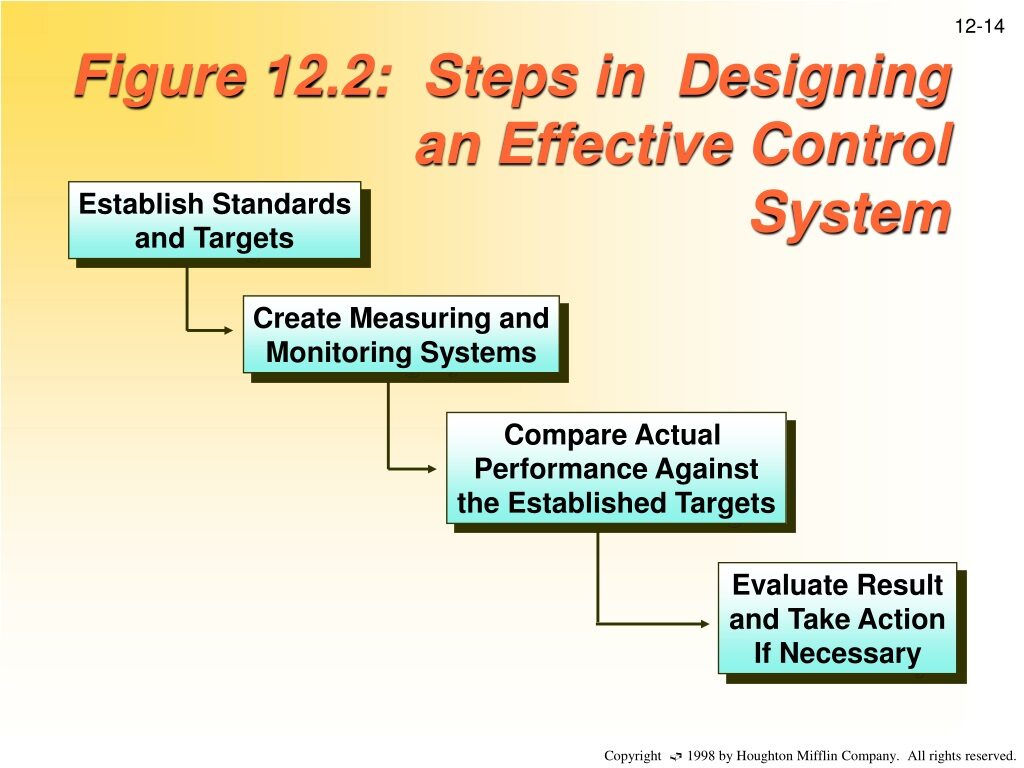

DC Motor Speed Control: Adjust Motor Speed using PWM is one example of the modern technologies used in industrial machine control systems, which are essential for enhancing performance, maintaining safety, and minimizing operational expenses. Creating an efficient control system involves strategic planning and the integration of advanced solutions. The following steps are key to developing an effective control setup

1. Understand System Requirements

Begin by analyzing the specific needs of the industrial machine. Consider factors such as speed, precision, load capacity, and environmental conditions. Define key performance indicators (KPIs) that will guide the design.

2. Select the Right Control Strategy

Select a control strategy that aligns well with the specific needs of the application. For instance, systems like IoT Based Automatic Changeover With Auto Gen Start/Stop demonstrate how modern solutions can enhance automation. Common control methods include:

- Open-loop control – Simple but lacks feedback for adjustments.

- Closed-loop control – Uses sensors to monitor performance and make real-time corrections.

- PID (Proportional-Integral-Derivative) control – A widely used closed-loop method for precise adjustments.

3. Choose Suitable Hardware and Software

Choosing the appropriate hardware is essential for a reliable and efficient system. Projects like How to Generate Electrical Energy with Footsteps Arduino highlight the importance of selecting suitable components. Key hardware elements typically include:

- Programmable Logic Controllers (PLCs) – Reliable and customizable for industrial automation.

- Sensors and actuators – Essential for feedback and machine responses.

- Human-Machine Interfaces (HMIs) – Enable operators to monitor and control processes easily.

Additionally, use industrial-grade software with user-friendly programming for efficient system configuration.

4. Implement Safety and Security Measures

Design the system with built-in safety features like emergency stops, fail-safes, and redundant controls. Cybersecurity is equally important—use firewalls, encryption, and restricted access to prevent unauthorized system manipulation.

5. Test and Optimize Performance

Before deployment, conduct thorough testing using simulations and real-world trials. Optimize control parameters to minimize energy consumption, reduce downtime, and enhance reliability.

6. Enable Remote Monitoring and Maintenance

Modern control systems integrate IoT technology, allowing for real-time monitoring and predictive maintenance. This reduces manual intervention and helps prevent unexpected failures.

Conclusion

Designing an efficient control system for industrial machines requires a blend of advanced technology and strategic planning. By incorporating automation, real-time monitoring, and robust safety measures, industries can achieve higher efficiency, lower costs, and improved reliability.