Introduction

Imagine walking into your favorite store, knowing that whatever you need will always be in stock. Sounds like magic, right? Well, it’s not magic it’s artificial intelligence (AI) at work! AI is revolutionizing supply chain management, making it smarter, faster, and more efficient. With AI-driven forecasting and inventory balancing, businesses can avoid stockouts, reduce excess inventory, and improve overall efficiency. Let’s dive into how AI is transforming supply chain inventories and why it’s a game-changer for businesses worldwide.

The Importance of Inventory Management

Inventory management is the backbone of any supply chain. Too much stock means wasted storage space and increased holding costs, while too little stock leads to lost sales and unhappy customers. Balancing inventory levels is crucial, and AI provides the tools to achieve that balance with precision.

How AI Enhances Supply Chain Forecasting

1. Leveraging Big Data for Better Predictions

Traditional inventory forecasting relied on historical sales data and gut instinct. AI, however, analyzes vast amounts of data, including market trends, weather conditions, economic indicators, and customer behavior, to make highly accurate predictions.

2. Machine Learning Algorithms for Demand Forecasting

Machine learning models continuously learn from new data, improving accuracy over time. These models identify seasonal trends, sudden demand spikes, and other patterns that humans might miss.

3. Predictive Analytics for Demand Planning

Predictive analytics enables companies to forecast demand at different levels from a single product to an entire supply chain network. AI-driven demand planning helps businesses optimize stock levels and minimize disruptions.

4. Real-Time Market Adaptation

AI continuously monitors market conditions and adjusts inventory forecasts accordingly. If an unexpected event disrupts the supply chain, AI-powered systems can quickly adapt, ensuring businesses remain agile and responsive.

AI-Driven Inventory Balancing

5. Automated Replenishment Systems

AI-powered inventory management systems automatically reorder stock when levels run low. This eliminates the guesswork and ensures optimal inventory levels at all times.

6. Reducing Overstock and Understock Issues

By accurately predicting demand, AI helps prevent overstocking (which ties up capital) and understocking (which leads to lost sales). This balance is crucial for maintaining profitability.

7. Optimizing Warehouse Operations

AI helps warehouses manage stock placement efficiently, reducing retrieval times and improving order fulfillment. This optimization leads to cost savings and increased efficiency.

8. Enhancing Supplier Collaboration

AI-driven inventory management fosters better communication between suppliers and retailers. Real-time data sharing enables suppliers to anticipate demand and adjust production schedules accordingly.

Key AI Technologies Used in Supply Chain Management

9. Natural Language Processing (NLP) for Data Analysis

NLP allows AI to interpret and analyze unstructured data, such as customer reviews and social media trends, helping businesses make informed inventory decisions.

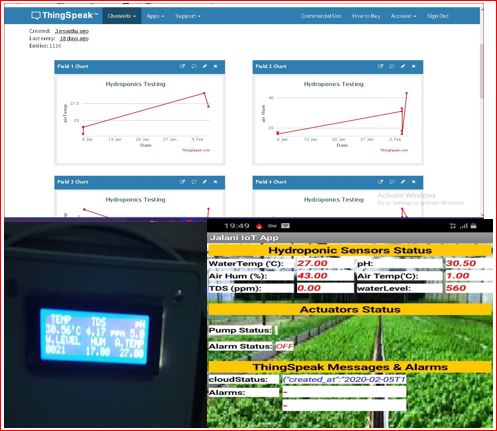

10. Internet of Things (IoT) Integration

IoT-enabled sensors track real-time inventory levels, providing accurate data for AI-driven forecasting. These sensors also monitor storage conditions, ensuring perishable goods remain fresh.

11. Computer Vision for Inventory Tracking

AI-powered computer vision systems use cameras to monitor inventory levels in warehouses and retail stores, automating stock audits and reducing human error.

12. Robotic Process Automation (RPA)

RPA automates repetitive supply chain tasks, such as order processing and invoice matching, reducing manual workload and improving efficiency.

The Benefits of AI in Supply Chain Inventories

13. Cost Reduction and Profit Maximization

AI-driven inventory management reduces excess stock, minimizes waste, and optimizes procurement, leading to significant cost savings and higher profits.

14. Improved Customer Satisfaction

With AI ensuring optimal inventory levels, customers experience fewer stockouts and faster order fulfillment, leading to higher satisfaction and brand loyalty.

15. Sustainability and Waste Reduction

AI helps businesses minimize overproduction and reduce waste, contributing to more sustainable supply chain practices.

Challenges of Implementing AI in Supply Chain Management

While AI offers numerous benefits, implementing it in supply chain management comes with challenges:

- High Initial Investment: AI technology requires significant investment in infrastructure, software, and employee training.

- Data Quality Issues: AI’s effectiveness depends on accurate and high-quality data.

- Integration with Existing Systems: Many businesses struggle to integrate AI with their legacy supply chain systems.

- Workforce Adaptation: Employees need to upskill to work alongside AI-powered systems.

The Future of AI in Supply Chain Inventory Management

AI is continuously evolving, and its impact on supply chain management will only grow. Future advancements may include:

- Advanced AI-driven autonomous warehouses that use robots and drones for faster order fulfillment.

- More sophisticated AI algorithms that predict supply chain disruptions before they occur.

- Hyper-personalized inventory recommendations based on individual customer preferences.

Conclusion

AI is not just a futuristic concept it is already transforming supply chain inventory management today. From predictive analytics to real-time tracking and automated replenishment, AI enables businesses to maintain the perfect inventory balance. While challenges exist, the benefits far outweigh the hurdles. As AI technology continues to advance, companies that embrace it will stay ahead of the competition, delivering better service, reducing costs, and maximizing efficiency. The future of supply chain management is intelligent, and AI is leading the way.

FAQs

1. How does AI improve demand forecasting in supply chains?

AI improves demand forecasting by analyzing large datasets, identifying patterns, and making accurate predictions based on real-time market conditions, customer behavior, and external factors.

2. Can small businesses benefit from AI-driven inventory management?

Yes! AI-powered inventory management solutions are becoming more affordable and accessible, allowing small businesses to optimize stock levels, reduce waste, and improve efficiency.

3. What are the biggest challenges of AI in supply chain management?

The biggest challenges include high implementation costs, data quality issues, integration with existing systems, and the need for employee training and adaptation.

4. How does AI help reduce supply chain waste?

AI minimizes overproduction, prevents spoilage, and optimizes resource allocation, contributing to more sustainable and environmentally friendly supply chain practices.

5. Is AI in supply chain management replacing human jobs?

AI is not replacing human jobs but rather enhancing efficiency by automating repetitive tasks. Employees can focus on more strategic roles that require human judgment and creativity.

Meta Description: Discover how AI is revolutionizing supply chain inventory management with smart forecasting, real-time tracking, and automated replenishment. Stay ahead with AI-driven solutions!