Introduction

Ever felt like your production line is moving at a snail’s pace? No matter how much effort you put in, bottlenecks seem to pop up like unwelcome guests at a party. That’s where AI swoops in like a superhero. Artificial intelligence (AI) algorithms are changing the game, offering precise insights into production inefficiencies and optimizing operations. In this article, we’ll explore how AI algorithms analyze and mitigate production bottlenecks, making manufacturing smoother, faster, and more efficient.

Understanding Production Bottlenecks

What Are Production Bottlenecks?

A production bottleneck occurs when a specific process in a manufacturing system slows down the entire workflow. Think of it as a single-lane road in an otherwise smooth highway everything behind it piles up, causing delays.

Common Causes of Bottlenecks

- Machine Downtime – Equipment failure or maintenance issues.

- Labor Shortages – Insufficient staff to keep up with demand.

- Supply Chain Delays – Late material deliveries slow production.

- Inefficient Processes – Poor workflow designs or outdated methods.

- Quality Control Issues – Defective products requiring rework.

How AI Identifies Production Bottlenecks

AI-Powered Data Collection

AI thrives on data. It continuously collects and processes information from sensors, IoT devices, and enterprise resource planning (ERP) systems. This data forms the foundation for identifying slow-moving processes.

Machine Learning for Bottleneck Detection

Machine learning (ML) algorithms analyze historical production data to identify patterns and anomalies. If one machine consistently slows down production, AI detects this trend before it becomes a major issue.

Real-Time Monitoring with AI

AI-driven monitoring systems track production in real time. By analyzing live data, AI pinpoints slowdowns and triggers alerts, allowing managers to take immediate action.

Predictive Analytics for Proactive Solutions

Rather than waiting for a bottleneck to cripple operations, predictive AI forecasts potential slowdowns. By analyzing past performance and external factors, AI predicts and prevents disruptions before they happen.

Types of AI Algorithms Used in Bottleneck Analysis

Neural Networks for Pattern Recognition

Neural networks mimic the human brain, learning from past production data to recognize inefficiencies. They adapt over time, improving their accuracy in spotting bottlenecks.

Decision Trees for Root Cause Analysis

Decision tree algorithms break down complex processes into a series of if-then scenarios. This helps in diagnosing the exact cause of a bottleneck.

Reinforcement Learning for Optimization

AI uses reinforcement learning to continuously adjust production strategies. By learning from trial and error, AI optimizes workflow efficiency and reduces bottlenecks.

Genetic Algorithms for Workflow Enhancement

Genetic algorithms simulate natural selection, testing different workflow configurations to find the most efficient one.

How AI Enhances Production Efficiency

Automated Scheduling and Resource Allocation

AI dynamically adjusts schedules and assigns resources to minimize bottlenecks. This ensures optimal machine utilization and labor efficiency.

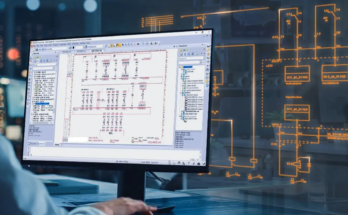

Digital Twins for Simulation Testing

A digital twin is a virtual replica of a production system. AI runs simulations on these models, testing various scenarios to identify potential bottlenecks before they occur in real life.

AI-Driven Quality Control

AI-powered quality control detects defects early, reducing rework and production delays. Computer vision systems inspect products in real time, ensuring consistency and efficiency.

Adaptive Manufacturing Systems

AI helps create adaptive manufacturing environments that respond to real-time data. Machines self-adjust their settings to maintain optimal production flow.

Overcoming Challenges in AI-Driven Bottleneck Analysis

Data Accuracy and Integration Issues

For AI to be effective, it needs high-quality, well-integrated data. Ensuring seamless communication between AI systems and existing infrastructure is crucial.

Resistance to AI Adoption

Employees may fear AI replacing jobs. Educating staff on AI’s role in enhancing efficiency rather than replacing workers can ease concerns.

Initial Implementation Costs

Setting up AI systems requires investment in technology and training. However, the long-term gains in efficiency and cost savings outweigh initial expenses.

Case Studies: AI in Action

Automotive Industry

A leading car manufacturer implemented AI-driven predictive maintenance, reducing machine downtime by 30% and eliminating production bottlenecks.

Food Processing

An AI-powered scheduling system optimized production lines, reducing waste and increasing output by 20%.

Electronics Manufacturing

AI-driven quality control reduced defect rates by 40%, preventing production slowdowns due to rework and recalls.

The Future of AI in Bottleneck Analysis

AI-Powered Autonomous Factories

Factories of the future will operate with minimal human intervention, relying on AI for real-time decision-making.

Advanced AI Collaboration with IoT

The integration of AI with IoT will enhance predictive analytics, providing even more precise bottleneck detection.

Self-Healing Manufacturing Systems

AI will enable self-healing production systems that automatically adjust workflows to prevent inefficiencies before they arise.

Conclusion

AI is revolutionizing the way manufacturers tackle production bottlenecks. From real-time monitoring to predictive analytics, AI-driven solutions are enhancing efficiency, reducing downtime, and optimizing workflows. While challenges exist, the benefits far outweigh the drawbacks. As AI continues to evolve, manufacturing will become smarter, faster, and more resilient.

FAQs

1. How does AI detect production bottlenecks?

AI analyzes real-time and historical data to identify slowdowns, patterns, and inefficiencies, helping manufacturers take proactive measures.

2. What industries benefit the most from AI-driven bottleneck analysis?

Industries like automotive, electronics, food processing, pharmaceuticals, and logistics benefit greatly from AI-driven efficiency improvements.

3. Can AI completely eliminate production bottlenecks?

While AI significantly reduces bottlenecks, some challenges, such as unexpected supply chain disruptions, may still occur.

4. What is the biggest challenge in implementing AI for bottleneck analysis?

Ensuring accurate data integration and overcoming resistance to AI adoption are major challenges in successful implementation.

5. How much does AI implementation cost for bottleneck analysis?

Costs vary depending on the complexity of the AI system, data infrastructure, and company size, but long-term savings often justify the investment.