Introduction

Imagine a factory where machines and humans work together seamlessly, exchanging information in real time to optimize production. Sounds futuristic, right? Well, thanks to artificial intelligence (AI), this future is already here. AI is revolutionizing smart manufacturing by enhancing worker collaboration, making processes more efficient, reducing errors, and fostering a more connected workforce. But how exactly does AI achieve this? Let’s dive in.

The Evolution of Smart Manufacturing

From Traditional to Smart Factories

Manufacturing has come a long way from the days of manual labor and assembly lines. The advent of automation, robotics, and now AI has transformed factories into high-tech environments where data-driven decisions rule.

The Role of Industry 4.0

Industry 4.0 has been a game-changer, integrating the Internet of Things (IoT), big data, and AI into manufacturing processes. This digital transformation enables real-time monitoring, predictive maintenance, and enhanced human-machine collaboration.

How AI Enhances Worker Collaboration

Real-Time Communication and Coordination

AI-powered systems facilitate real-time communication between workers and machines. Smart assistants, chatbots, and AI-driven dashboards help employees stay informed about production statuses, maintenance schedules, and safety alerts.

Intelligent Task Allocation

AI algorithms analyze workloads and skill sets to assign tasks efficiently. By understanding worker strengths, AI ensures that tasks are distributed optimally, boosting productivity and job satisfaction.

Predictive Maintenance for Minimal Downtime

Imagine a scenario where a machine breaks down unexpectedly, halting production. AI prevents this by predicting equipment failures before they happen, allowing workers to address issues proactively and minimize disruptions.

Digital Twins for Better Decision-Making

Digital twins virtual replicas of physical systems—help workers visualize production processes in real time. AI analyzes these models, offering actionable insights to improve efficiency and reduce waste.

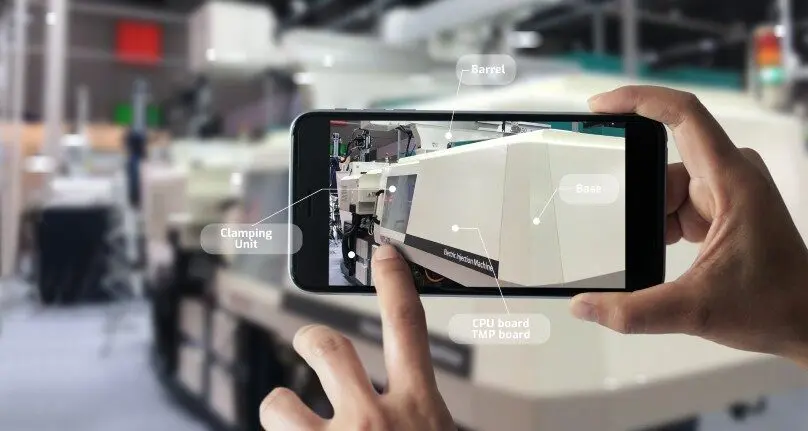

Augmented Reality (AR) for Hands-On Assistance

AI-driven AR tools provide real-time guidance to workers, overlaying digital instructions onto physical equipment. This reduces errors, speeds up training, and enhances overall efficiency.

AI-Powered Robotics in Collaborative Workspaces

Cobots (collaborative robots) work alongside human employees, handling repetitive tasks while workers focus on more strategic roles. AI ensures these cobots adapt to human movements, ensuring safety and efficiency.

How to Design A Direct Online Starter for Five 3-Phase Motors

AI-Enhanced Training Programs

AI-driven training platforms personalize learning experiences, offering interactive modules and virtual simulations. This enables workers to acquire new skills quickly and stay up to date with industry advancements.

AI for Safety and Risk Management

Workplace safety is a top priority, and AI helps by monitoring environments for hazards. AI-powered sensors detect unsafe conditions, alerting workers and supervisors before accidents occur.

The Benefits of AI-Driven Worker Collaboration

Increased Efficiency and Productivity

By automating routine tasks and optimizing workflows, AI enhances overall productivity, allowing workers to focus on high-value tasks.

Improved Decision-Making

AI provides data-driven insights that help workers make informed decisions quickly, reducing errors and improving quality.

Enhanced Employee Satisfaction

With AI handling mundane tasks, employees can engage in more meaningful work, leading to higher job satisfaction and reduced burnout.

Reduced Operational Costs

Optimized processes and predictive maintenance reduce downtime and waste, ultimately lowering manufacturing costs.

Strengthened Supply Chain Management

AI helps manage inventory, forecast demand, and streamline logistics, ensuring a smooth supply chain and reducing delays.

Challenges of Implementing AI in Smart Manufacturing

Workforce Resistance to Change

Employees may fear AI replacing jobs. Proper training and communication are essential to show AI as a tool for enhancement rather than replacement.

High Initial Investment

AI implementation requires significant investment in technology, infrastructure, and training. However, long-term benefits often outweigh initial costs.

Data Privacy and Security Concerns

With AI handling vast amounts of data, ensuring cybersecurity is critical to protect sensitive information from breaches.

Need for Skilled Workforce

AI requires skilled personnel for maintenance and operation. Upskilling workers through AI-driven training programs is essential for a smooth transition.

The Future of AI in Worker Collaboration

AI-Powered Hyperautomation

The next phase of AI in manufacturing involves hyperautomation, where AI autonomously manages entire workflows, further enhancing efficiency.

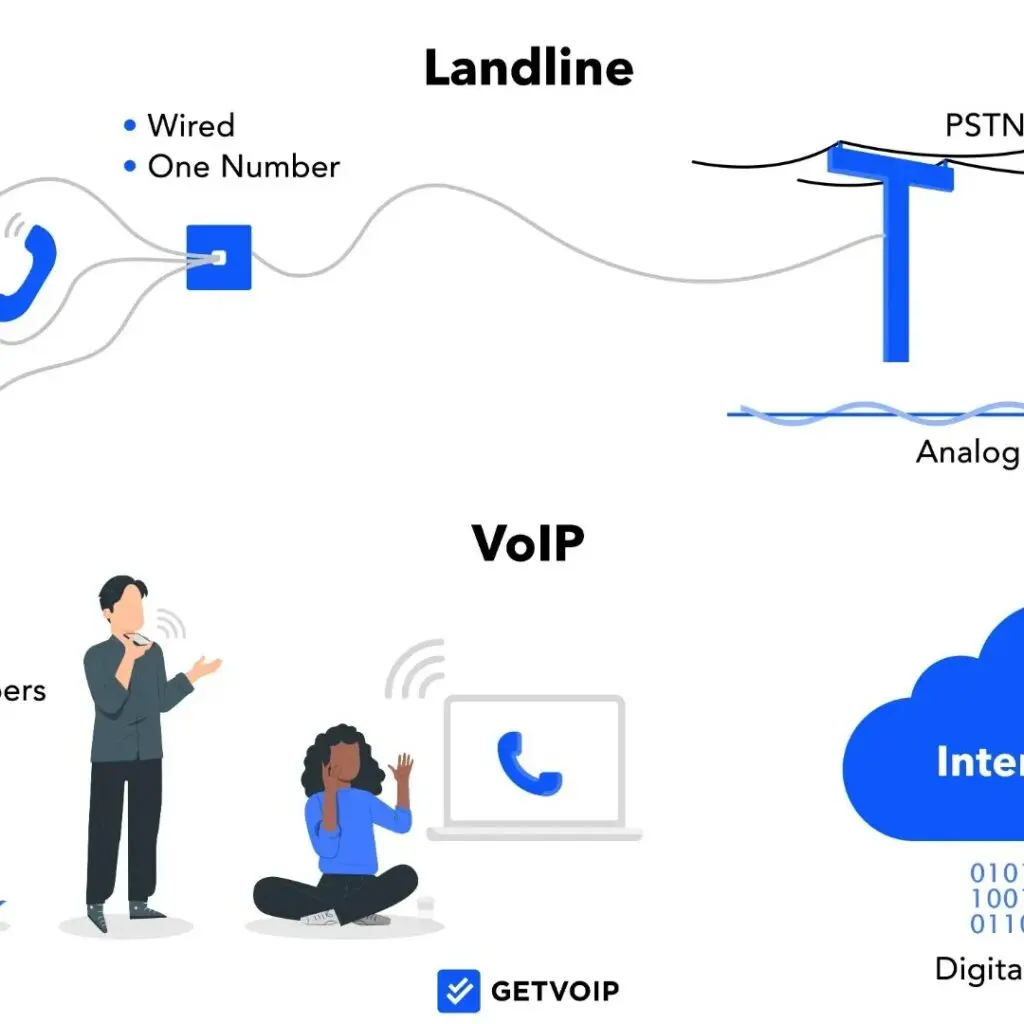

The Role of 5G in AI-Driven Collaboration

5G connectivity will improve data transmission speeds, enabling real-time AI applications for even more seamless worker collaboration.

AI and Blockchain Integration

Combining AI with blockchain technology will enhance data security, ensuring transparent and tamper-proof record-keeping in manufacturing processes.

Human-Centric AI Design

Future AI systems will focus on enhancing human potential, ensuring technology complements rather than replaces workers.

Conclusion

AI is redefining the way workers collaborate in smart manufacturing environments. From real-time communication and predictive maintenance to AI-powered training and safety monitoring, AI is a game-changer. While challenges exist, the benefits far outweigh them, paving the way for a more efficient, safe, and productive manufacturing sector. As AI continues to evolve, its role in enhancing worker collaboration will only grow, making factories smarter and workplaces more engaging.

FAQs

1. How does AI improve communication in manufacturing?

AI enhances communication through smart assistants, real-time dashboards, and chatbots that provide instant updates on production statuses, maintenance needs, and safety alerts.

2. Can AI replace human workers in manufacturing?

No, AI is designed to complement human workers by automating repetitive tasks, enhancing decision-making, and improving safety rather than replacing jobs entirely.

3. What are cobots, and how do they enhance worker collaboration?

Cobots are collaborative robots that work alongside human employees, assisting with repetitive tasks while ensuring safety and efficiency through AI-driven adaptability.

4. How does AI contribute to workplace safety?

AI monitors factory environments using sensors to detect potential hazards, sending alerts to workers and supervisors to prevent accidents.

5. What are the biggest challenges in implementing AI in smart manufacturing?

The main challenges include workforce resistance, high initial investment, data security concerns, and the need for skilled personnel to manage AI systems.