Introduction

AI in real-time Supply Chains, in a world where businesses can track every single movement of goods across a vast, multi-layered supply chain in real time. Sounds like a dream? Well, thanks to artificial intelligence (AI), it’s already a reality. With increasing globalization and complex supply networks, traditional methods of monitoring supply chains are becoming obsolete. Enter AI: a game-changer that brings speed, accuracy, and efficiency to real-time supply chain monitoring.

Understanding Multi-Layer Supply Chains

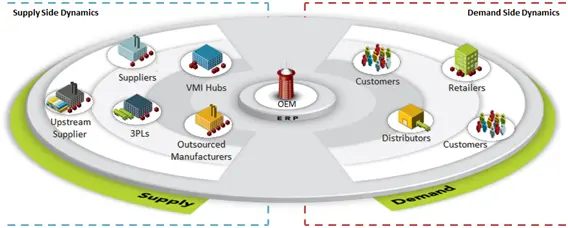

What is a Multi-Layer Supply Chain?

A multi-layer supply chain consists of multiple tiers of suppliers, manufacturers, distributors, and retailers working together to deliver a final product to consumers. Unlike linear supply chains, multi-layered systems involve intricate relationships and dependencies, making them harder to manage manually.

Challenges of Multi-Layer Supply Chains

Managing a multi-layer supply chain isn’t a walk in the park. Here are some common challenges:

- Lack of Visibility: It’s difficult to track products across different suppliers and locations.

- Delays and Disruptions: Natural disasters, geopolitical tensions, and supplier issues can cause delays.

- Data Overload: Massive amounts of data make it challenging to extract actionable insights.

- Inefficient Communication: Poor collaboration among stakeholders leads to inefficiencies.

How AI Transforms Real-Time Supply Chain Monitoring

1. AI-Powered Predictive Analytics

AI-driven predictive analytics helps companies foresee potential disruptions before they occur. By analyzing historical data and real-time inputs, AI can predict delays, demand fluctuations, and supply shortages.

2. IoT and AI for Live Tracking

The Internet of Things (IoT) integrates with AI to provide real-time tracking of shipments. Sensors on goods transmit data about location, temperature, humidity, and handling conditions, ensuring optimal quality control.

3. Machine Learning for Anomaly Detection

Machine learning (ML) algorithms analyze supply chain data to detect anomalies such as fraud, counterfeit products, or unexpected delays. This enhances security and reduces financial risks.

4. AI-Driven Demand Forecasting

The Impact of AI on Workforce Training in Smart Manufacturing

AI can analyze market trends, customer behavior, and external factors to predict demand accurately. This prevents overstocking or understocking, leading to cost savings and improved efficiency.

5. Autonomous Decision-Making

Using AI for Predicting Supply Chain Disruptions in Manufacturing

AI-enabled systems can make autonomous decisions, such as rerouting shipments in case of disruptions, optimizing inventory levels, and suggesting supplier alternatives.

6. Blockchain and AI for Transparency

By integrating blockchain with AI, supply chains gain enhanced transparency and security. Blockchain records transactions immutably, while AI verifies data integrity and identifies inconsistencies.

7. Chatbots and Virtual Assistants for Supplier Communication

AI-powered chatbots streamline supplier communication, providing instant updates, answering queries, and resolving issues without human intervention.

8. Digital Twins for Supply Chain Simulation

AI-Powered Smart Factory Automation: A Beginner’s Guide

A digital twin is a virtual replica of a physical supply chain. AI-driven simulations help businesses test different scenarios, optimize routes, and enhance logistics efficiency.

Benefits of AI in Real-Time Supply Chain Monitoring

Improved Visibility

AI provides end-to-end visibility into supply chain operations, helping companies track inventory, shipments, and supplier performance in real time.

Enhanced Efficiency

Automation powered by AI reduces manual errors, speeds up decision-making, and optimizes resource allocation.

Cost Reduction

By preventing stockouts, minimizing wastage, and improving forecasting accuracy, AI-driven supply chains significantly reduce operational costs.

Risk Mitigation

AI can identify potential risks such as supplier failures, geopolitical disruptions, and fraud, enabling proactive decision-making.

Sustainability and Compliance

AI ensures compliance with environmental regulations by monitoring emissions, waste management, and ethical sourcing practices.

Industries Benefiting from AI-Driven Supply Chains

1. Retail and E-Commerce

AI helps retailers track inventory levels, predict demand, and ensure timely deliveries, enhancing customer satisfaction.

2. Healthcare and Pharmaceuticals

In the pharmaceutical industry, AI ensures the safe and timely delivery of medicines by monitoring temperature-sensitive shipments.

3. Automotive

Automakers use AI to track component availability, optimize manufacturing schedules, and reduce production delays.

4. Food and Beverage

AI-powered tracking ensures food safety by monitoring storage conditions, expiration dates, and supply chain compliance.

5. Manufacturing

AI optimizes raw material procurement, reduces waste, and enhances production efficiency in manufacturing.

Future Trends in AI-Enabled Supply Chain Monitoring

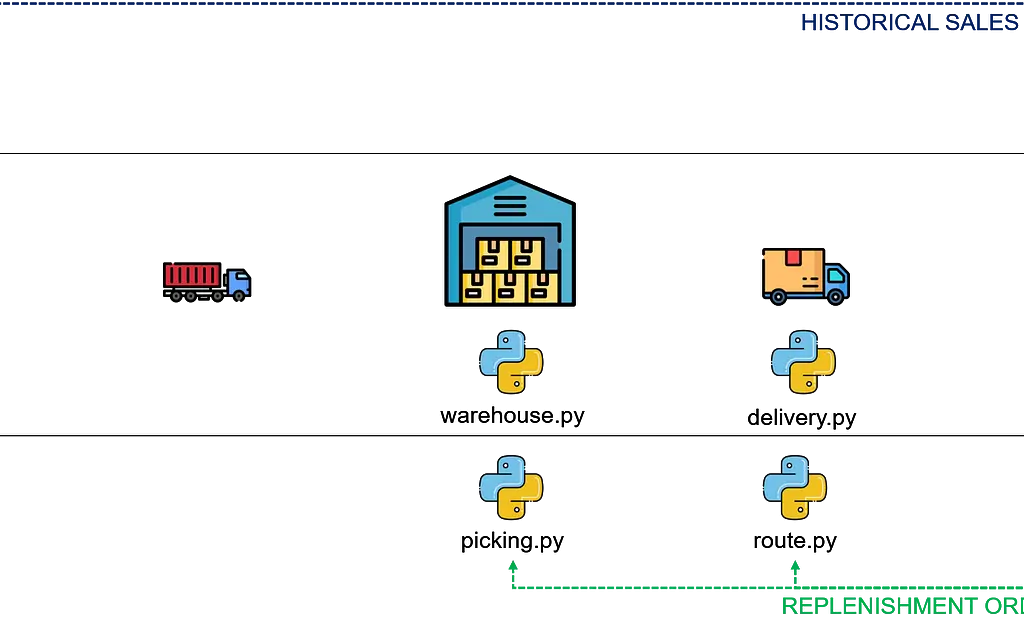

1. AI-Powered Robotics in Warehousing

Autonomous robots powered by AI will manage inventory, pick and pack goods, and enhance warehouse efficiency.

2. Hyperautomation in Supply Chain Operations

Combining AI with robotic process automation (RPA) will lead to hyperautomation, reducing manual intervention in logistics.

3. AI-Driven Sustainability Initiatives

AI will help companies achieve sustainability goals by optimizing energy consumption, reducing carbon footprints, and minimizing waste.

4. Advanced AI-Generated Insights

Future AI models will provide even more granular insights into supply chain performance, improving decision-making capabilities.

5. AI-Augmented Human Decision Making

AI will not replace human decision-makers but will augment their abilities, providing data-driven insights for strategic planning.

Conclusion

The integration of AI in real-time monitoring of multi-layer supply chains is not just an innovation it’s a necessity in today’s fast-paced global economy. From predictive analytics to blockchain integration, AI-driven supply chains offer enhanced visibility, efficiency, and risk management. As technology continues to evolve, businesses that embrace AI will gain a competitive edge, ensuring seamless operations and improved customer satisfaction. The future of supply chain management is smart, automated, and AI-powered. Are you ready to embrace it?

FAQs

1. How does AI improve supply chain visibility?

AI provides real-time tracking, predictive analytics, and anomaly detection, ensuring complete transparency across supply chain layers.

2. Can AI prevent supply chain disruptions?

Yes, AI predicts potential disruptions by analyzing historical and real-time data, allowing businesses to take proactive measures.

3. How does AI-powered demand forecasting work?

AI analyzes market trends, customer behavior, and external factors to predict demand accurately, reducing stock imbalances.

4. What role does blockchain play in AI-driven supply chains?

Blockchain ensures data integrity and transparency, while AI analyzes transactions to detect anomalies and optimize processes.

5. What industries benefit the most from AI in supply chain management?

Retail, healthcare, automotive, food and beverage, and manufacturing industries leverage AI for enhanced efficiency, cost savings, and risk mitigation.