AI in manufacturing cost optimization, in the world of manufacturing, efficiency and cost-effectiveness are paramount. With the rise of artificial intelligence (AI), businesses are experiencing a paradigm shift in how they optimize costs and streamline operations. But how exactly is AI changing the game in manufacturing? Let’s dive in and explore how this powerful technology is reshaping the industry and helping companies cut costs while improving quality and productivity.

The Role of AI in Manufacturing Cost Optimization

AI is no longer a futuristic concept; it’s here and actively transforming industries, with manufacturing at the forefront. At its core, AI brings advanced data analytics, automation, and predictive modeling to the table, which are invaluable tools for cost optimization. By leveraging AI, manufacturers can achieve more with less, all while reducing waste and increasing profits.

Predictive Maintenance: Preventing Costly Downtime

One of the most significant ways AI is helping manufacturers save money is through predictive maintenance. Imagine the scenario: your factory is humming along, machines working at full capacity, but then boom! One machine breaks down, halting production and racking up repair costs. This is where AI steps in. By analyzing real-time data from sensors and other sources, AI can predict when a machine is likely to fail, allowing maintenance teams to fix it before it becomes a costly issue.

Think of it like your car’s engine light it warns you that something’s wrong before it breaks down completely. This approach not only reduces downtime but also extends the lifespan of expensive equipment, saving manufacturers a significant amount of money in repairs and replacements.

Optimizing Supply Chains with AI

In any manufacturing process, the supply chain plays a crucial role in determining costs. From raw materials to finished products, inefficiencies can quickly add up. AI helps optimize supply chains by predicting demand, managing inventory levels, and identifying cost-saving opportunities.

Through AI-driven algorithms, manufacturers can get insights into the best suppliers, negotiate better prices, and avoid overstocking or understocking. This means less waste, fewer storage costs, and a more efficient flow of materials. It’s like having a crystal ball that tells you exactly when to reorder, so you never have too much or too little.

Enhancing Energy Efficiency in Manufacturing

Energy consumption is one of the largest operational expenses in manufacturing. But AI can help reduce these costs significantly. By using AI to monitor and analyze energy usage across machines and processes, manufacturers can identify patterns and inefficiencies that humans might miss.

AI-powered systems can adjust settings in real time to optimize energy consumption, ensuring that machines only use as much power as needed. Think of it like a smart thermostat for your factory it keeps things running efficiently while keeping energy costs in check.

Automation: Streamlining Production Processes

Automation is one of the most obvious applications of AI in manufacturing. Automated systems, powered by AI, can perform repetitive tasks with precision, speed, and consistency. This not only boosts productivity but also minimizes human error, which can lead to costly mistakes.

Take the assembly line, for example. With AI-driven robots and machines, manufacturers can speed up production, reduce labor costs, and improve the consistency of the finished product. These automated systems can also adjust on the fly to accommodate changes in demand or production specifications, ensuring that everything runs smoothly without costly delays.

AI in Quality Control: Reducing Defects and Waste

Quality control is another area where AI is making a huge impact. In traditional manufacturing processes, quality control is often a manual task that relies on human inspectors to catch defects. However, this method can be error-prone, and defects can slip through the cracks, leading to wasted materials and costly rework.

AI, on the other hand, can quickly analyze large amounts of data and identify defects in real time. Using machine vision, AI can detect tiny flaws in products that the human eye might miss. By catching these defects early in the production process, manufacturers can reduce waste and improve product quality, which ultimately leads to cost savings.

AI-Driven Product Design for Cost Efficiency

AI isn’t just about optimizing existing processes; it’s also revolutionizing product design. Engineers and designers can use AI-powered tools to simulate and optimize product designs, making them more cost-effective from the start. AI can suggest materials, designs, and production methods that reduce costs without compromising quality.

This means that companies can create products that are easier and cheaper to manufacture, leading to lower production costs and higher profit margins. In the competitive world of manufacturing, this kind of cost efficiency is a game-changer.

Labor Cost Reduction through AI and Automation

Labor is one of the most significant costs in any manufacturing operation. While automation and AI do require an initial investment, they can ultimately reduce labor costs by taking over repetitive or dangerous tasks. This allows human workers to focus on more skilled, high-value tasks, improving overall productivity.

Moreover, AI can also help optimize workforce management. By analyzing employee performance data and predicting labor needs, AI can help companies schedule shifts more efficiently and ensure they have the right number of workers on the floor at any given time. This leads to better labor allocation and lower labor costs.

AI in Demand Forecasting: Aligning Production with Market Needs

Accurate demand forecasting is crucial for manufacturing cost optimization. If a company overproduces, it risks holding excess inventory, leading to higher storage costs and potential waste. On the other hand, underproducing can lead to missed sales opportunities and increased rush-order costs.

AI excels at analyzing vast amounts of historical data and identifying patterns that help predict future demand. By accurately forecasting demand, manufacturers can adjust production schedules, reduce overproduction, and ensure they’re meeting market needs without incurring unnecessary costs.

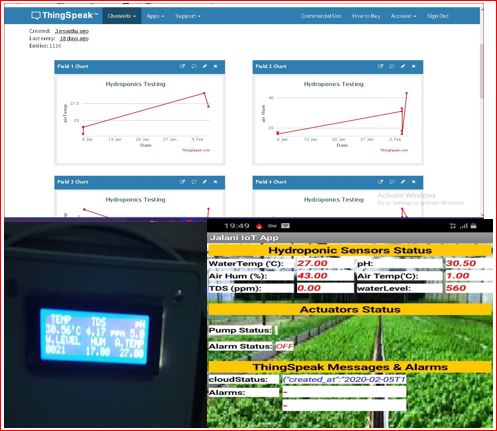

Real-Time Data Analytics: Making Smarter Decisions

AI-powered real-time data analytics is another way manufacturers are cutting costs. In the past, managers had to rely on slow-moving reports and guesswork to make decisions about operations, supply chains, and production. Today, AI offers real-time insights into every aspect of manufacturing.

For example, AI systems can track machine performance, production rates, and inventory levels in real time, allowing managers to make informed decisions quickly. With AI’s help, businesses can respond to issues as they arise, adjust operations, and avoid costly delays.

AI in Sustainability: Cutting Costs and Promoting Green Practices

Sustainability is more important than ever, and manufacturers are increasingly looking for ways to reduce their environmental impact. AI can play a big role in this by helping companies reduce waste, conserve energy, and streamline their processes to be more eco-friendly.

AI can also assist in optimizing logistics and transportation, minimizing fuel consumption, and reducing carbon emissions. By promoting green practices and cutting waste, AI helps manufacturers save money while contributing to a more sustainable future.

Challenges and Considerations in AI Implementation

While the benefits of AI in manufacturing are clear, implementing AI technologies comes with its challenges. The initial investment can be high, and companies may need to invest in new infrastructure, retrain employees, or integrate AI with existing systems. Furthermore, data privacy and cybersecurity concerns must be addressed to ensure that sensitive information remains secure.

Despite these challenges, the long-term benefits of AI far outweigh the costs, especially when it comes to manufacturing cost optimization. Companies that embrace AI are positioning themselves for success in a rapidly changing market.

AI-Powered Cost Optimization: The Future of Manufacturing

Looking ahead, AI’s role in manufacturing will only continue to grow. As AI technology advances, we can expect even more sophisticated tools for cost optimization, from advanced machine learning algorithms to cutting-edge automation systems.

The future of manufacturing lies in smart factories, where AI, automation, and data analytics work seamlessly together to optimize every aspect of production. These factories will be more efficient, more sustainable, and more cost-effective than ever before.

Conclusion: Embracing AI for a Competitive Edge

AI is transforming the manufacturing landscape, offering businesses the tools they need to optimize costs, boost efficiency, and improve product quality. From predictive maintenance to AI-driven automation and energy efficiency, the possibilities are endless. As manufacturers continue to embrace AI, they will unlock new levels of cost savings and productivity, ensuring their competitive edge in an increasingly dynamic market.

The Benefits of Forest Bathing: How Nature Therapy Can Improve Your Well-being

FAQs

1. How does AI help with predictive maintenance in manufacturing?

AI helps by analyzing real-time data from sensors and other sources to predict when equipment will fail, allowing for preemptive repairs before costly breakdowns occur.

2. What role does AI play in optimizing supply chains?

AI analyzes data to predict demand, manage inventory levels, and identify cost-saving opportunities, leading to more efficient and cost-effective supply chain management.

3. Can AI improve energy efficiency in manufacturing?

Yes, AI can monitor and adjust energy usage in real-time, ensuring machines consume only as much energy as necessary, thus reducing energy costs.

4. How does AI impact labor costs in manufacturing?

AI reduces labor costs by automating repetitive tasks, allowing human workers to focus on higher-value activities, ultimately improving productivity.

5. Is AI the future of manufacturing cost optimization?

Absolutely! As AI technology advances, its ability to optimize manufacturing processes and reduce costs will only increase, making it an essential tool for future competitiveness.