Introduction

Imagine you’re running a manufacturing business, and suddenly, your key supplier delays a shipment due to unforeseen circumstances. Chaos ensues production stalls, costs rise, and customers grow impatient. Wouldn’t it be great if you could see these disruptions coming and act before they hit? That’s exactly what AI is bringing to the table in modern supply chain management.

By leveraging artificial intelligence, manufacturers can predict and mitigate supply chain disruptions, ensuring smoother operations and better decision-making. In this article, we’ll explore how AI is revolutionizing supply chain management and why it’s a game-changer for manufacturers worldwide.

The Growing Importance of AI in Supply Chain Management

Supply chains are more complex than ever, involving multiple stakeholders, fluctuating demand, and unpredictable risks. AI, powered by machine learning and big data analytics, is transforming how businesses anticipate and handle disruptions.

What Are Supply Chain Disruptions?

Supply chain disruptions refer to unexpected events that interfere with the normal flow of goods and materials. These can be caused by:

- Natural disasters

- Political instability

- Supplier failures

- Cyberattacks

- Transportation issues

AI helps manufacturers foresee these disruptions, making proactive decision-making possible.

How AI Predicts Supply Chain Disruptions

AI works by analyzing vast amounts of data, detecting patterns, and forecasting potential risks. Here’s how it does the magic:

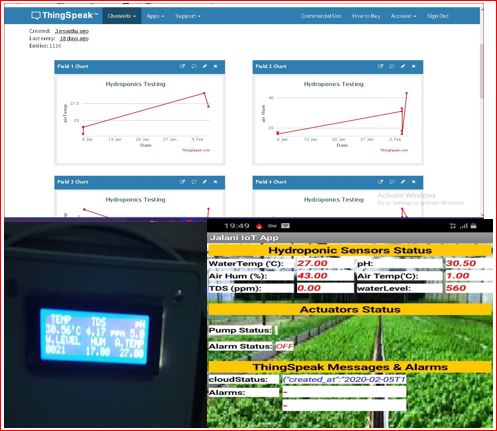

1. Real-Time Data Collection and Analysis

AI collects and processes data from multiple sources, including supplier databases, weather forecasts, geopolitical updates, and IoT sensors. This real-time data helps manufacturers stay ahead of possible disruptions.

2. Machine Learning Models for Risk Assessment

Machine learning algorithms analyze historical data to identify trends and patterns. By continuously learning from past disruptions, AI can predict future risks with remarkable accuracy.

3. Predictive Analytics for Demand and Supply

By examining historical demand patterns, AI forecasts inventory needs, preventing shortages or overstocking. It helps businesses balance supply with demand efficiently.

4. Natural Language Processing (NLP) for Market Analysis

AI-powered NLP tools scan news, social media, and industry reports to detect potential risks. If there’s political unrest in a key supplier’s country, AI flags it as a potential disruption.

5. IoT and AI Integration for Real-Time Monitoring

Smart IoT devices track shipments, warehouse conditions, and manufacturing processes. AI interprets this data to predict failures before they happen, ensuring timely action.

The History of Free Love: How the Sexual Revolution Shaped Modern Relationships

The Benefits of AI in Supply Chain Management

1. Improved Supply Chain Resilience

With predictive insights, businesses can build contingency plans, reducing the impact of disruptions and improving overall resilience.

2. Cost Reduction and Efficiency

AI optimizes logistics, reduces waste, and minimizes downtime, leading to significant cost savings.

3. Enhanced Supplier and Vendor Management

AI evaluates supplier performance based on reliability, past delays, and risk factors, helping businesses choose the best partners.

4. Faster Decision-Making

AI-driven insights enable supply chain managers to make faster, data-driven decisions, reducing reaction times to disruptions.

5. Increased Customer Satisfaction

Predicting and preventing delays ensures timely deliveries, leading to happier customers and stronger brand loyalty.

Real-World Applications of AI in Supply Chain Disruption Prediction

1. Automotive Industry

Car manufacturers use AI to predict disruptions in semiconductor supply, ensuring production doesn’t come to a halt.

2. Retail and E-commerce

Retailers leverage AI to anticipate inventory shortages, adjusting orders proactively.

3. Pharmaceutical Industry

AI helps pharma companies predict raw material shortages, ensuring timely drug production.

4. Food and Beverage Industry

AI forecasts disruptions in agricultural supply chains, allowing businesses to adjust procurement strategies.

Challenges in Implementing AI for Supply Chain Predictions

While AI offers immense potential, implementing it in supply chain management comes with challenges:

1. Data Quality and Availability

AI relies on accurate data. Poor data quality or lack of sufficient historical records can hinder its effectiveness.

2. High Initial Investment

AI implementation requires significant investment in technology, infrastructure, and skilled personnel.

3. Integration with Legacy Systems

Many manufacturers still rely on outdated supply chain management systems that may not easily integrate with AI technologies.

4. Cybersecurity Concerns

With increased digitalization, AI systems become potential targets for cyberattacks. Ensuring robust cybersecurity measures is crucial.

Future of AI in Supply Chain Disruption Prediction

AI in supply chain management is constantly evolving. Here are some future trends to watch:

1. Blockchain and AI Integration

Blockchain ensures data transparency, while AI uses this data to enhance predictive accuracy.

2. Autonomous Supply Chain Networks

Self-learning AI systems will automate decision-making, reducing the need for human intervention.

3. Advanced Robotics and AI

AI-driven robots will streamline warehouse operations, improving efficiency and reducing reliance on manual labor.

4. AI-Powered Digital Twins

Digital twins virtual replicas of supply chains will allow businesses to simulate and predict disruptions before they occur.

Conclusion

AI is no longer a futuristic concept it’s a present-day necessity for manufacturers aiming to stay competitive in an unpredictable world. By predicting supply chain disruptions, AI empowers businesses to mitigate risks, optimize operations, and maintain customer trust. While challenges exist, the benefits far outweigh them, making AI an indispensable tool for modern supply chain management.

FAQs

1. How does AI help in predicting supply chain disruptions?

AI analyzes historical data, real-time inputs, and external factors to detect patterns and predict potential disruptions before they happen.

2. What industries benefit the most from AI in supply chain management?

Industries like automotive, retail, pharmaceuticals, and food production benefit greatly from AI-driven supply chain predictions.

3. What are the biggest challenges in using AI for supply chain disruption prediction?

Challenges include data quality issues, high implementation costs, integration difficulties, and cybersecurity risks.

4. Can AI completely prevent supply chain disruptions?

While AI significantly reduces the impact of disruptions, it cannot eliminate them entirely. It provides businesses with the insights needed to react quickly and effectively.

5. Is AI in supply chain management expensive to implement?

Initial investment can be high, but over time, AI reduces costs through improved efficiency, better forecasting, and risk mitigation, making it a worthwhile investment.

Meta Description: Discover how AI is revolutionizing manufacturing by predicting supply chain disruptions. Learn how machine learning, IoT, and predictive analytics enhance efficiency and resilience.