Introduction

In today’s rapidly evolving business landscape, supply chain management is no longer just about moving goods from point A to point B. It’s about real-time tracking, transparency, and agility. With the integration of Artificial Intelligence (AI) and the Internet of Things (IoT), companies can enhance supply chain visibility to unprecedented levels. This article will delve into how these technologies are revolutionizing supply chain management, the benefits they offer, and the challenges that come with their adoption.

The Role of Supply Chain Visibility in Modern Business

In a global market where disruptions can occur at any time whether due to natural disasters, geopolitical instability, or pandemics having a clear view of your supply chain is critical. Without visibility, companies are left in the dark about where their goods are, how they’re moving, and when they’ll arrive. This lack of information can lead to inefficiencies, missed deadlines, and increased costs. By integrating AI and IoT, businesses can monitor and manage their supply chains effectively, ensuring they’re responsive to changes and can quickly adapt.

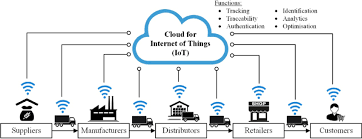

The Synergy Between AI and IoT in Supply Chain Management

AI and IoT are two powerful technologies that, when combined, can transform supply chain management. IoT involves connecting devices—sensors, devices, and software—across the supply chain, allowing for real-time data collection. These connected devices can provide insights into inventory levels, shipment status, and equipment health. AI, on the other hand, uses machine learning algorithms to analyze this data, making predictions, identifying patterns, and enabling smarter decision-making.

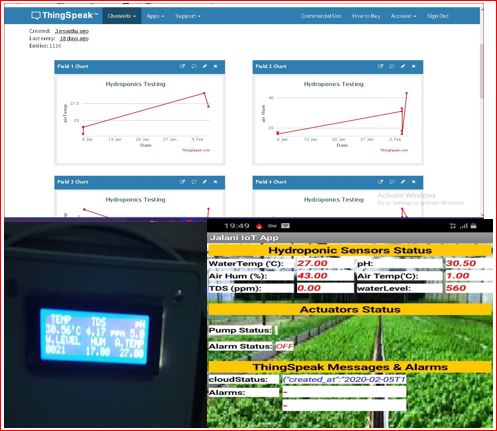

Real-Time Monitoring and Data Collection

One of the key benefits of integrating IoT in supply chains is real-time monitoring. Sensors can track the location, temperature, humidity, and condition of goods during transportation. For example, perishable goods like pharmaceuticals and fresh food can be monitored for temperature fluctuations that could spoil the product. Real-time data collection ensures that any anomalies can be detected early, minimizing risks to the supply chain.

Predictive Analytics for Proactive Management

AI’s ability to process vast amounts of data allows for predictive analytics, which can forecast demand, supply chain risks, and even supply chain disruptions. Machine learning algorithms can analyze historical data, seasonal trends, and market factors to predict stock levels and reorder times accurately. This proactive management helps businesses avoid stockouts and overstock situations, optimizing inventory levels and reducing carrying costs.

Benefits of AI and IoT Integration in Supply Chains

The integration of AI and IoT in supply chain management offers several key benefits:

- Improved Efficiency: By automating routine processes and using predictive analytics, companies can streamline operations. This reduces manual intervention, minimizes errors, and increases efficiency across the supply chain.

- Enhanced Visibility: Real-time data collected through IoT devices provides complete visibility into the supply chain. This allows managers to track goods from production to the end consumer, ensuring that everything is on schedule and nothing is lost or delayed.

- Cost Savings: The ability to predict demand and optimize inventory reduces excess stock and associated costs. Additionally, real-time monitoring can detect inefficiencies and prevent waste, leading to significant cost savings.

- Better Risk Management: With AI’s predictive capabilities, companies can identify potential disruptions before they happen. This allows for quicker decision-making and alternative planning, reducing downtime and financial losses.

- Customer Satisfaction: Increased visibility means customers are more informed about their orders’ status. Whether it’s an e-commerce customer tracking their package or a manufacturer knowing the precise location of a critical component, better communication enhances customer satisfaction.

Challenges in Adopting AI and IoT in Supply Chains

While the benefits are clear, there are challenges to consider when integrating AI and IoT into supply chains:

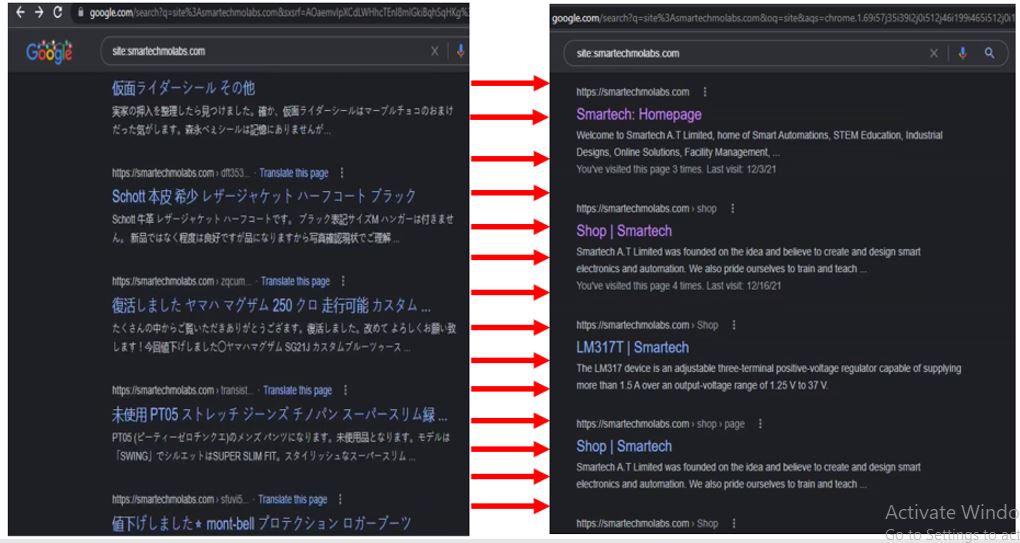

- Data Privacy and Security: With more connected devices, the risk of data breaches increases. Companies must implement robust cybersecurity measures to protect sensitive information.

- High Initial Investment: The deployment of IoT devices and AI systems can be costly. Companies must invest in infrastructure, hardware, and software, which can be a barrier for smaller businesses.

- Complexity of Integration: The integration of AI and IoT systems requires specialized knowledge and expertise. Many businesses struggle with the complexity of implementation, from hardware selection to software compatibility.

- Resistance to Change: Employees may be hesitant to adopt new technologies. Training and change management are critical to ensure a smooth transition and maximize the benefits of these technologies.

- Lack of Standardization: There is currently no universal standard for IoT devices and AI systems. This lack of interoperability can make integration difficult, leading to fragmented systems and reduced efficiency.

Check: Shocking Truth! Forget RAM – This Spec Matters MOST for Mobile Gaming

Strategies for Effective Integration

To successfully integrate AI and IoT into the supply chain, businesses should consider the following strategies:

- Invest in Training and Education: Ensure that employees at all levels understand how to use the new technologies. Training programs should focus on both the technical aspects and the operational benefits.

- Start Small: Begin with a pilot project to test the integration of AI and IoT. This approach allows businesses to learn from the process and make adjustments before scaling up.

- Collaborate with Technology Providers: Work closely with IoT and AI experts who can provide guidance and support throughout the integration process. Their experience can help avoid common pitfalls.

- Focus on Scalability: Design systems that can be easily scaled as the business grows. This approach prevents businesses from having to redo their infrastructure when they expand.

- Leverage Cloud Computing: Cloud-based platforms can provide the flexibility needed to manage the vast amounts of data generated by IoT devices. This ensures that businesses can access real-time information from anywhere, enhancing supply chain visibility.

Conclusion

The integration of AI and IoT into supply chains is not just a trend it’s a necessity for companies looking to stay competitive in today’s market. By providing real-time visibility and predictive insights, these technologies enable businesses to respond quickly to changes, optimize operations, and reduce costs. While there are challenges, the rewards far outweigh the hurdles. As technology continues to evolve, businesses that embrace these innovations will be better positioned to thrive in a fast-paced global economy.

FAQs

- What is the difference between AI and IoT in supply chain management?

- AI involves the use of machine learning and data analysis to make informed decisions, while IoT focuses on connecting devices to gather real-time data. Together, they provide a comprehensive view of the supply chain.

- How can businesses overcome the high initial investment required for AI and IoT integration?

- Businesses can start with pilot projects to test the waters without a large upfront investment. They can also look for funding opportunities and collaborate with technology providers to mitigate costs.

- What role does cybersecurity play in integrating AI and IoT in supply chains?

- Cybersecurity is crucial to protect sensitive data from breaches. Businesses must implement strong security measures to safeguard against hacking and unauthorized access.

- Can small businesses benefit from AI and IoT integration in supply chains?

- Yes, small businesses can benefit by starting with scalable solutions that fit their budget. Many technologies are now available at a lower cost, making them accessible to smaller enterprises.

- What future trends should businesses watch in AI and IoT for supply chain management?

- Future trends include the use of blockchain for enhanced transparency, the adoption of predictive maintenance for machinery, and the increased use of AI for real-time decision-making.