This blog post is about How To Build A 3-Phase Forward and Reverse Motor Control System panel. The forward and reverse control system is a motor control system, It works both front and back. We use it to change the direction of rotation of motors, mostly industrial motors.

The panel includes a contactor for each direction as well as a selector switch, which is a two-way switch for each direction of the motor. When you turn the switch to the to the right hand side, the forward direction contactor will be energized, and the motor will rotate in the forward direction. When you turn the switch in the left hand direction, the forward-direction contact will de-energize and the reverse-direction contactor will energize, and the motor rotates in the reverse direction.

3-Phase Motor Control System: The Components Required

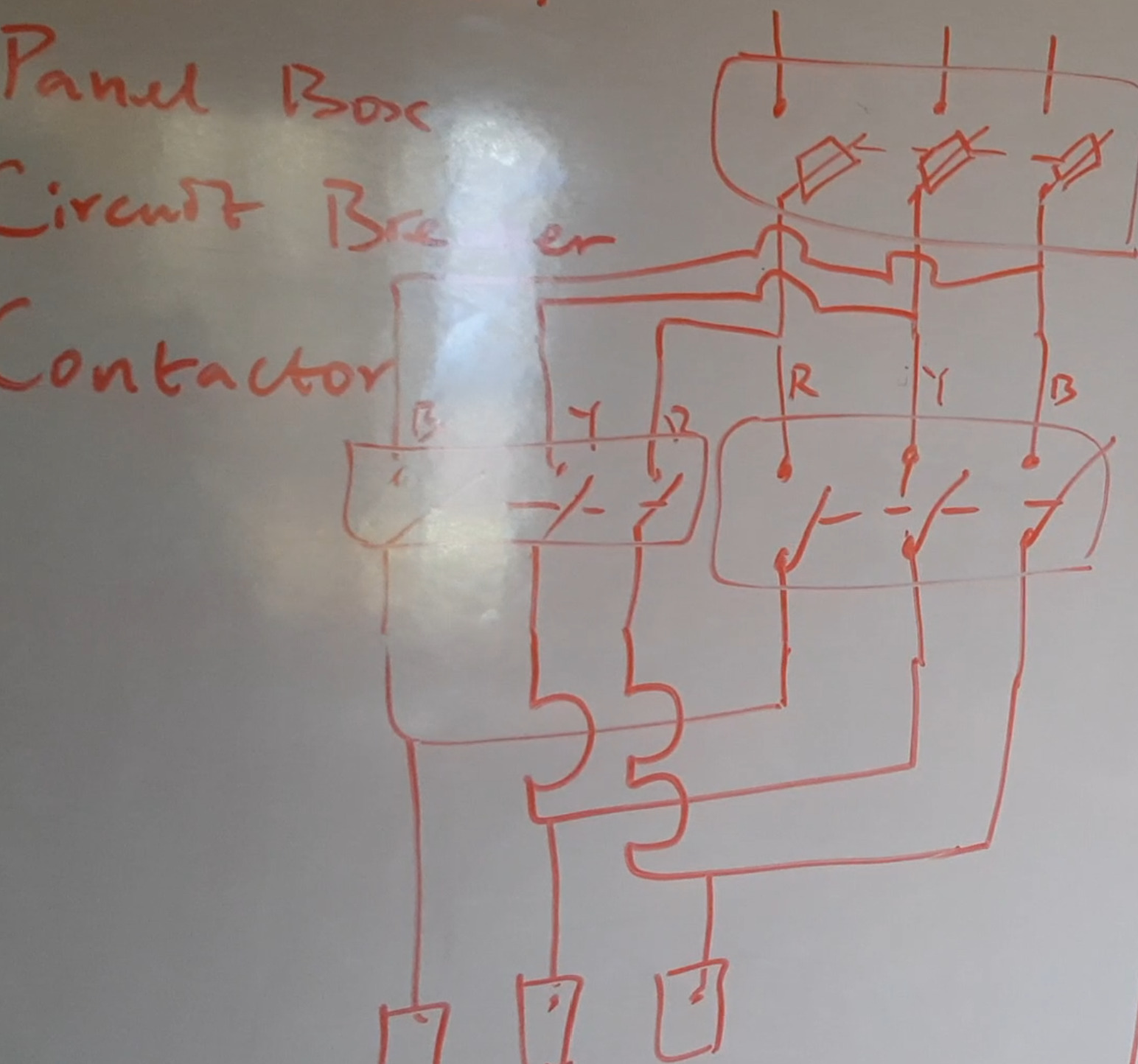

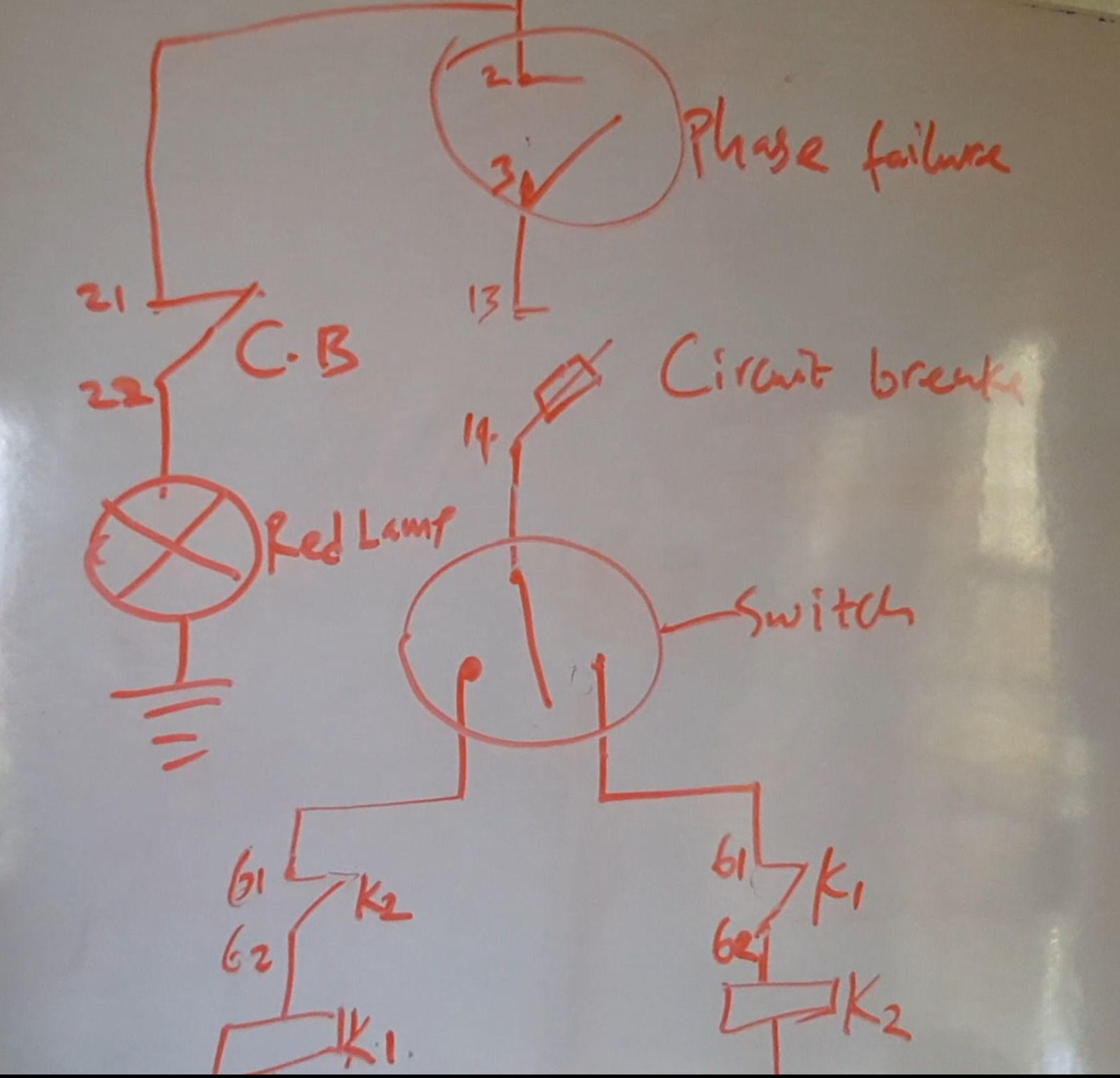

Schematic Diagram of 3-Phase Motor Control System

The schematic diagram above shows the basic components for the panel box design. The selector switch used, the circuit breaker and contactors.

It also shows that the 3-phase motor design also accounts for phase failure and placed a lamp indicator for such. The Switch function is also shown diagrammatically.

Step-by-Step Project Implementation

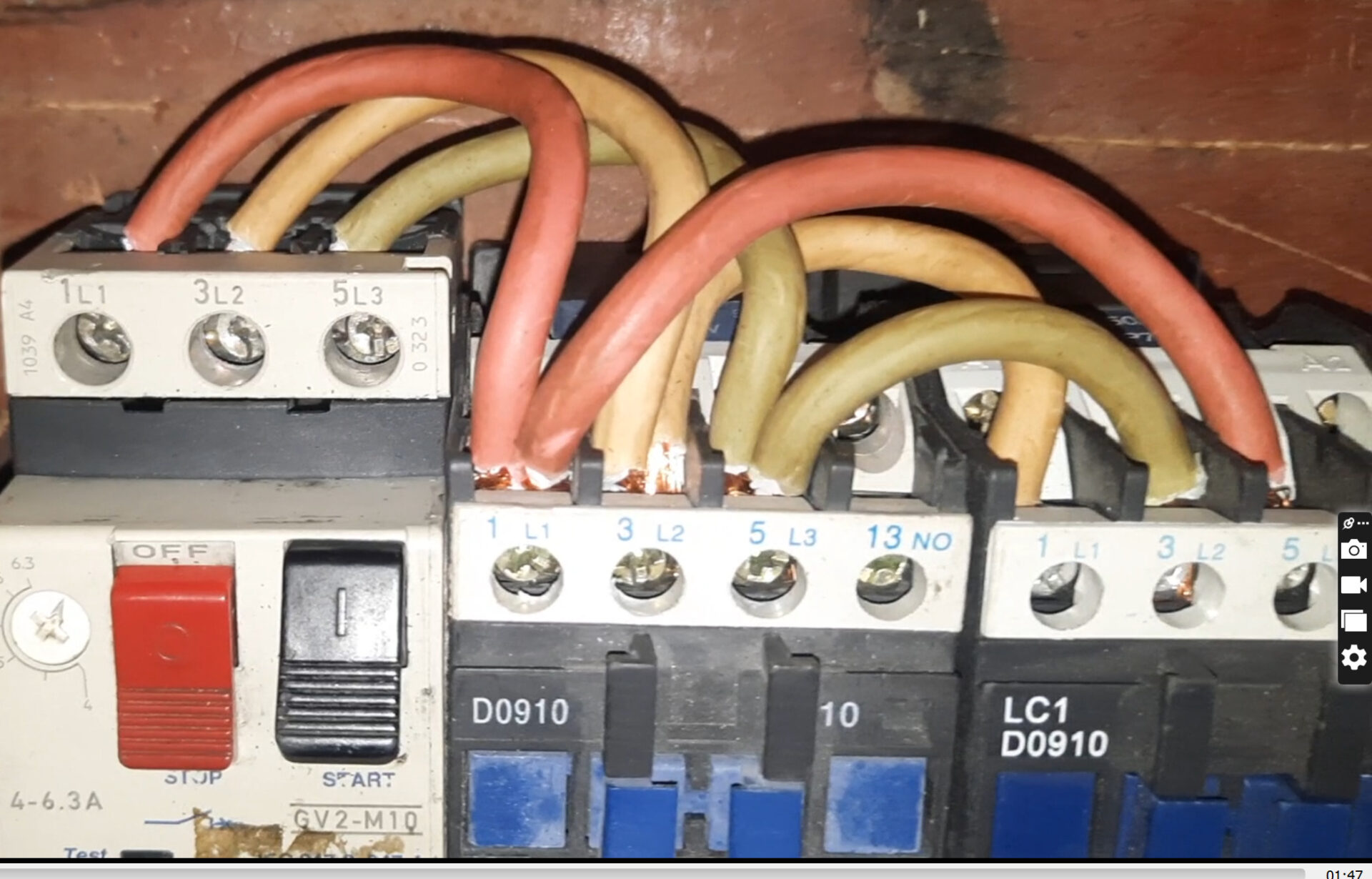

Hardware Connection

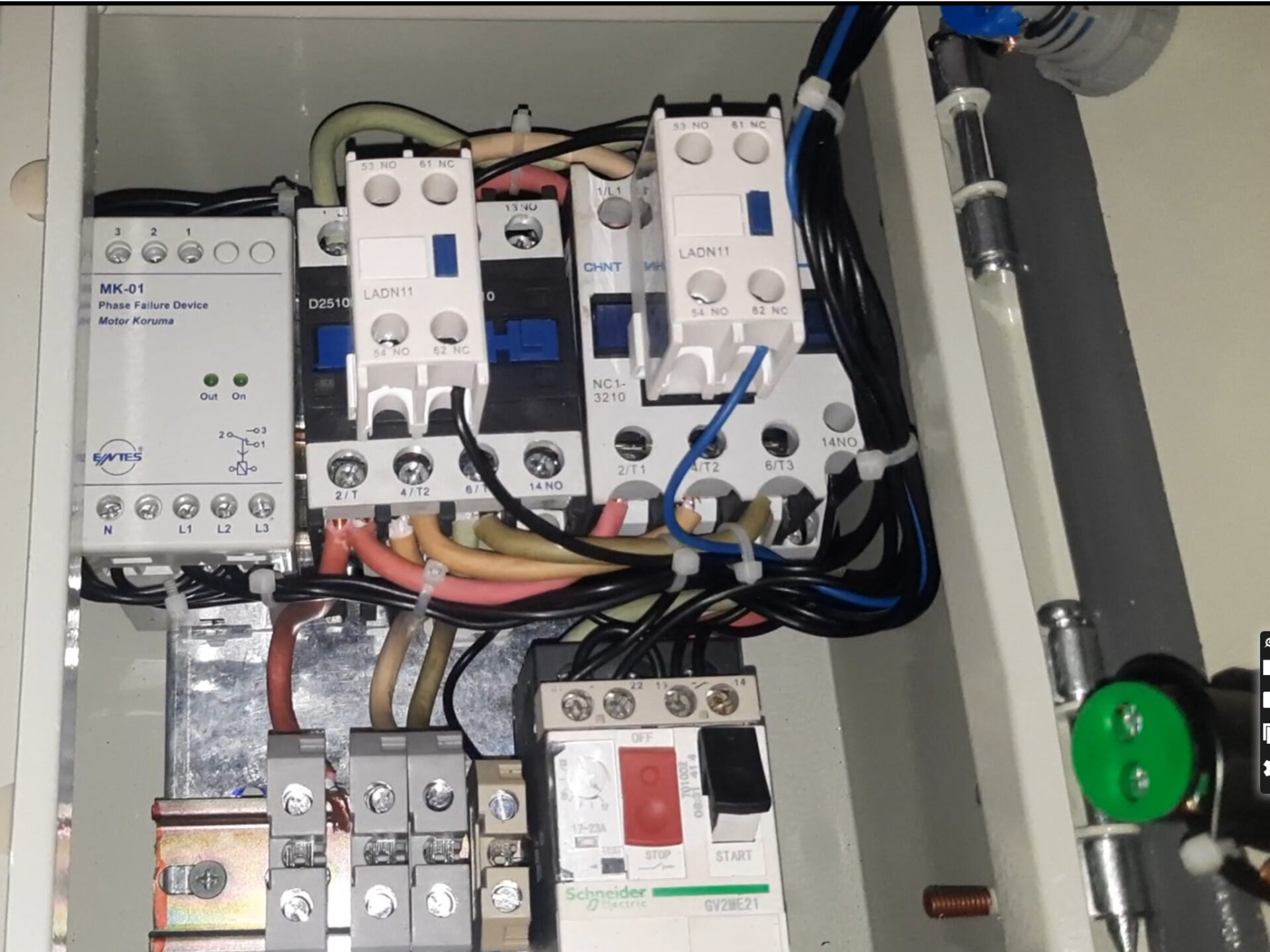

The connections are made as shown above. We loped each phase of the contactors accordingly then connected each phase of this to the 3 phase breaker. The L1, L2, L3 shown below represents the line 1, line 2 and line 3 which can mean the red phase, green phase, and the yellow phase of the industrial motor.

And the NO means “normally open” whereas the NC means noramlly closed. This is important to know because the contactor would need one of these for auxillary connections.

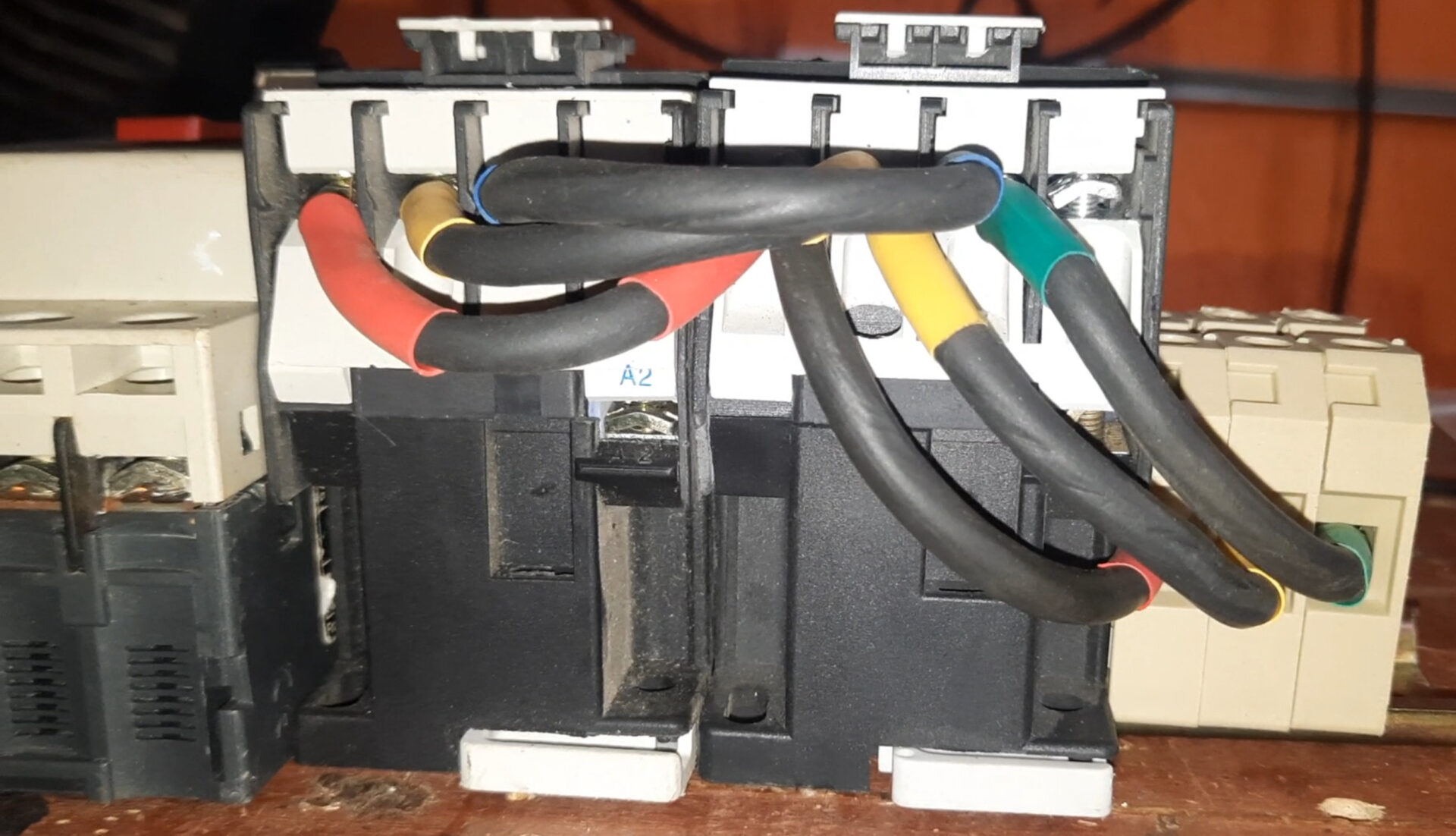

We used a connector to make the outputs of these phases or terminals terminate. This is important because we want to connect the phase input wires of the industrial motor to this connectors.

Encasing and Tidying Up

To know when those contactors are on, the panel has indicator light for each direction contactor. The panel also has volt-monitor for each phases. The volt-monitor display the reading of the voltage in each phases. As well it has a circuit breaker, known as MOTOR PROTECTION CIRCUIT BREAKER (MPCB), the breaker protect the panel and the motor from overloading, short circuit, loss of imbalance, by tripping. A red indicator light is also added to know when the know when the breaker as trip.

And it also has a three-phase failure relay. A phase failure relay is a protective device that monitors the voltage and phase sequence of the three-phase power supply. If any of the phases are lost or if the phase sequence is incorrect, the relay will de-energize it’s output contact and disconnect the load from the power supply.

Testing and Deployment

To test the design, we used a single phase power and looped the remaining phases with the same phase line. As shown above, we connected the input lines of the circuit breaker and the wire is plugged into an AC voltage of 220V.

The breaker is turned on afterwards and the phase failure’s indicator LED glows up, after a while it is seen to change the LED color to green. We can see the rating of each voltage supplied on each phase on the voltmeter indicator on the panel.

When we turn the selector switch toward the right hand side prompting forward direction of the 3-phase motor, the pilot lamp on the right to the selector switch would turn on as shown above.

The backward direction of the 3-phase motor is made possible when the selector switch is flipped towards the left hand side. The indicator light turn on showing the motor has reversed its direction.

Read More Posts Like This

- Arduino Smart Light Control Benefits

- Arduino Smart Light Control Project Ideas

- Design An RFID-Based Access Control with Disinfectant Booth

- 3d Atom Model Project Ideas

Conclusion

The post has explained step-by-step How To Build a 3-Phase Motor Control System using all the components outlined in the this post. We would like to know if this blog post was helpful to you. Leave us a comment in the comment section. Thank you.

FAQs

What is a 3-phase motor control system?

A 3-phase motor control system is an electronic device that controls the speed and torque of a 3-phase motor. It is used in a wide variety of applications, including industrial machinery, robotics, and home appliances.

What are the components of a 3-phase motor control system?

The basic components of a 3-phase motor control system include:

- A microcontroller: This is the brain of the system and is responsible for controlling the speed and torque of the motor.

- Power transistors: These are used to switch the current to the motor windings.

- Driver circuitry: This is used to protect the power transistors and motor from damage.

- Sensors: These are used to provide feedback to the microcontroller about the motor’s speed, torque, and position.

How does a 3-phase motor control system work?

The microcontroller sends a signal to the driver circuitry, which then switches the current to the motor windings. The current flowing through the windings creates a rotating magnetic field, which causes the motor to rotate. The microcontroller also monitors the feedback from the sensors and adjusts the signal to the driver circuitry accordingly.

What are the different types of 3-phase motor control systems?

There are a number of different types of 3-phase motor control systems, but the most common are:

- Variable-frequency drive (VFD): This is the most common type of 3-phase motor control system. It controls the speed of the motor by varying the frequency of the AC voltage supplied to the motor.

- Pulse-width modulation (PWM): This is another common type of 3-phase motor control system. It controls the speed of the motor by varying the duty cycle of the PWM signal.

- Field-oriented control (FOC): This is a more advanced type of 3-phase motor control system that can provide more precise control of the motor’s speed and torque.

What are the applications of 3-phase motor control systems?

3-phase motor control systems are used in a wide variety of applications, including:

- Industrial machinery: 3-phase motors are used in a wide variety of industrial machinery, such as pumps, fans, and conveyors.

- Robotics: 3-phase motors are used in a wide variety of robots, including arms, manipulators, and drones.

- Home appliances: 3-phase motors are used in a wide variety of home appliances, such as washing machines, dryers, and refrigerators.

What are the essential components of a 3-phase motor control system?

A basic 3-phase motor control system typically consists of the following components:

- Microcontroller: The microcontroller serves as the system’s control center, responsible for managing the motor’s speed, torque, and other operational parameters.

- Power Transistors: These transistors act as switches, controlling the flow of current to the motor windings. They handle the high power requirements of the motor.

- Driver Circuitry: This circuitry protects the power transistors and motor from damage caused by voltage spikes, overcurrent conditions, and other electrical hazards.

- Sensors: Various sensors provide feedback to the microcontroller, monitoring the motor’s speed, torque, position, and other crucial parameters.

What types of 3-phase motor control systems are commonly used?

The three most prevalent types of 3-phase motor control systems are:

- Variable-Frequency Drive (VFD): This system regulates the motor’s speed by adjusting the frequency of the AC voltage supplied to the motor. It’s widely used in industrial applications.

- Pulse-Width Modulation (PWM): This system controls the motor’s speed by altering the duty cycle of a PWM signal sent to the motor windings. It’s a common choice for robotics and servo applications.

- Field-Oriented Control (FOC): This advanced system provides precise control of both the motor’s speed and torque by utilizing feedback from sensors to optimize motor performance. It’s often used in high-performance applications.

What are the primary applications of 3-phase motor control systems?

3-phase motor control systems are employed in a wide range of applications, including:

- Industrial Machinery: These systems power various industrial machines, such as pumps, fans, conveyors, and CNC machines, providing efficient and controlled operation.

- Robotics: 3-phase motors are essential components in robots, enabling precise control of movement and articulation in robotic arms, manipulators, and drones.

- Home Appliances: Household appliances like washing machines, dryers, and refrigerators often utilize 3-phase motors controlled by these systems to achieve desired performance levels.

- Electric Vehicles (EVs): 3-phase motors play a crucial role in electric vehicles, providing efficient and controlled propulsion for cars, motorcycles, and other EVs.

- Renewable Energy Systems: 3-phase motors are often used in wind turbines and solar power generation systems to convert natural energy into usable electricity.

How can I learn more about building 3-phase motor control systems?

Numerous resources are available to expand your knowledge of 3-phase motor control systems:

- Technical Books: Several books delve into the theoretical foundations and practical aspects of designing and implementing 3-phase motor control systems.

- Online Courses and Tutorials: You can contact us to train you for this. Also, numerous online platforms offer courses and tutorials that provide step-by-step guidance on building and programming 3-phase motor control systems.

- Manufacturer Documentation: Equipment manufacturers often provide detailed documentation and application notes for their 3-phase motor control products, offering valuable insights into their operation and configuration.

- Technical Papers and Journals: Research papers and articles published in technical journals offer in-depth discussions and advancements in 3-phase motor control techniques.

- Online Forums and Communities: Online forums and communities dedicated to electronics and motor control provide a platform for asking questions, sharing experiences, and collaborating with fellow enthusiasts.