Introduction

Have you ever wondered how some manufacturing industries consistently deliver high-quality products while minimizing waste and reducing costs? The secret often lies in leveraging cutting-edge technologies, particularly Artificial Intelligence (AI). AI-driven process optimization in continuous manufacturing is transforming the way industries operate, bringing efficiency, precision, and sustainability to new heights. In this article, we’ll dive deep into how AI is revolutionizing continuous manufacturing, its benefits, and what the future holds for this dynamic field.

What Is Continuous Manufacturing?

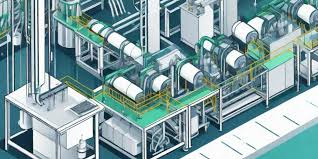

Continuous manufacturing refers to a production process where materials are continuously moved through various stages of production without interruption. Unlike batch manufacturing, where production occurs in discrete steps, continuous manufacturing is seamless, leading to greater efficiency and consistency.

The Role of AI in Manufacturing

AI is a game-changer in many industries, but its impact on manufacturing is particularly profound. By analyzing vast amounts of data, predicting outcomes, and automating processes, AI helps manufacturers make smarter decisions faster. From predictive maintenance to quality control, AI is reshaping the landscape of production.

How AI Drives Process Optimization

AI in continuous manufacturing works by integrating advanced algorithms and machine learning models into the production line. Here’s how:

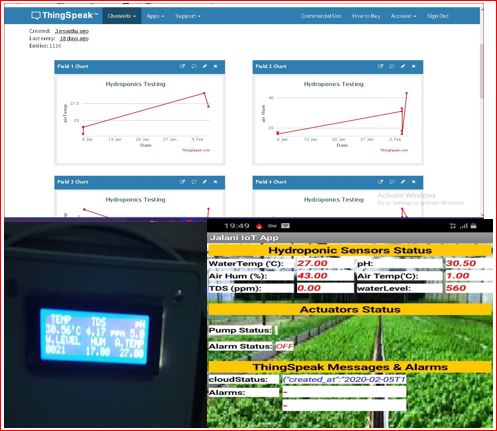

Data Analysis and Insights

Manufacturing processes generate enormous amounts of data from sensors, machines, and systems. AI analyzes this data in real-time to identify patterns, inefficiencies, and areas for improvement.

Predictive Maintenance

Imagine if a machine could tell you it’s about to break down before it actually does. AI enables predictive maintenance by analyzing machine performance data, reducing downtime, and preventing costly repairs.

Quality Control

AI-powered systems can identify defects in products faster and more accurately than human inspectors. Using technologies like computer vision, AI ensures that only top-quality products reach customers.

Process Automation

Automation isn’t just about robots on assembly lines. AI-driven automation optimizes workflows, reduces manual intervention, and ensures consistent production speeds.

Benefits of AI in Continuous Manufacturing

The adoption of AI in continuous manufacturing offers numerous advantages, including:

Enhanced Efficiency

AI helps streamline processes, eliminate bottlenecks, and maximize resource utilization, resulting in faster production times.

Cost Reduction

By minimizing waste, reducing energy consumption, and predicting maintenance needs, AI significantly cuts operational costs.

Improved Product Quality

With AI-driven quality control, manufacturers can maintain consistent standards, ensuring customer satisfaction and reducing returns or recalls.

Sustainability

AI’s ability to optimize resource usage and reduce waste contributes to more sustainable manufacturing practices.

Real-World Applications

Let’s look at some industries where AI-driven process optimization is making waves:

Pharmaceuticals

In pharmaceutical manufacturing, AI ensures consistent drug quality and speeds up production timelines. Continuous manufacturing supported by AI has been pivotal in vaccine production.

Food and Beverage

AI optimizes production lines, ensuring food safety and reducing spoilage in the food and beverage sector.

Electronics

Precision is key in electronics manufacturing. AI enhances accuracy in component placement, reducing defects and improving overall device performance.

Automotive

AI optimizes assembly lines, enhances quality control, and streamlines supply chain management in the automotive industry.

Human Evolution: Stone Tools Used by Early Humans and Monkeys

Challenges in Implementing AI in Manufacturing

Despite its benefits, implementing AI in continuous manufacturing isn’t without challenges. These include:

High Initial Costs

The cost of integrating AI systems and upgrading existing infrastructure can be steep.

Skill Gap

Employees need training to work with AI-driven tools and systems, which can be time-consuming and costly.

Data Security

With AI heavily reliant on data, protecting sensitive information from breaches is critical.

Resistance to Change

Adopting new technologies often meets resistance from employees accustomed to traditional methods.

Overcoming Challenges

Manufacturers can overcome these hurdles by:

- Investing in training programs to upskill employees.

- Partnering with AI experts to ensure smooth implementation.

- Adopting robust cybersecurity measures.

- Gradually integrating AI solutions to ease the transition.

Future Trends in AI and Continuous Manufacturing

The future of AI-driven process optimization in manufacturing is bright. Emerging trends include:

Edge Computing

Processing data closer to the production site will reduce latency and enhance real-time decision-making.

Digital Twins

Digital twins virtual replicas of physical systems allow manufacturers to simulate and optimize processes before implementation.

Collaborative Robots (Cobots)

Cobots, powered by AI, will work alongside humans, enhancing productivity and safety.

AI-Powered Supply Chains

From demand forecasting to inventory management, AI will revolutionize supply chain operations.

Steps to Get Started with AI in Manufacturing

If you’re considering adopting AI in your manufacturing processes, here’s how to get started:

- Identify Pain Points: Determine areas in your production process that need improvement.

- Collect Data: Ensure you have access to high-quality data from your systems.

- Choose the Right Tools: Select AI solutions tailored to your specific needs.

- Start Small: Begin with pilot projects before scaling up.

- Evaluate and Adapt: Continuously monitor the impact of AI and refine your strategies.

Conclusion

AI-driven process optimization is more than a trend it’s the future of continuous manufacturing. By embracing AI, manufacturers can achieve unparalleled efficiency, quality, and sustainability, ensuring they stay competitive in an ever-evolving market. So, whether you’re in pharmaceuticals, automotive, or any other manufacturing sector, now is the time to harness the power of AI and transform your production processes.

FAQs

1. What is the main advantage of AI in continuous manufacturing?

AI improves efficiency and quality while reducing costs and waste, making manufacturing processes more sustainable and competitive.

2. How does AI ensure product quality in manufacturing?

AI uses technologies like machine learning and computer vision to detect defects and maintain consistent quality standards.

3. Is AI implementation expensive for manufacturers?

While initial costs can be high, the long-term savings from increased efficiency, reduced waste, and lower downtime often outweigh the investment.

4. What industries benefit most from AI-driven manufacturing?

Industries like pharmaceuticals, food and beverage, electronics, and automotive are seeing significant benefits from AI in continuous manufacturing.

5. How can small manufacturers adopt AI?

Small manufacturers can start with affordable AI solutions, such as predictive maintenance tools, and gradually expand their capabilities as they see returns on investment.