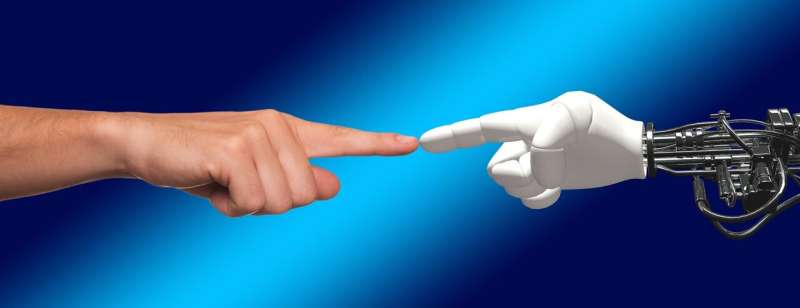

We frequently move objects around when picking them up in an effort to achieve the best grip. A robotic hand that performs a similar function has now been created by a research team, a development that could improve the development of assistive robots.

The group developed a robotic hand that can fully rotate a variety of objects in the lab of Aaron Dollar, professor of mechanical engineering, materials science, and computer science. This is true even when the grippers of the robotic hand occasionally lose touch with the object. In the most current issue of IEEE Robotics and Automation Letters, the findings were published.

Lead author of the study and Ph.D. student in Dollar’s lab Andrew Morgan explained that the goal of the project was to develop a tool “where the fingers are always expanding and shutting, altering their placement on the actual object.”

A previous Ph.D. student, Raymond Ma, developed the original concept for the hand. For the newer version, Morgan modified the design to enable more advanced in-hand capabilities. These includes new fingertip designs and an adaptation of the internal wrist rotation.

One potential application, he said, is for assembly purposes. For instance, the device could pick up an object and reorient it so that it can insert it into a slot or place it down in a certain way.

The researchers set out to make the hand relatively simple, with as little sensor technology as possible. The point is to make a practical device that’s not too expensive or requires too much maintenance. “It required us to make a more robust system than what has traditionally been required,” Morgan said.

o make the gripper move, the team uses a tendon-driven, underactuated transmission, which Morgan said is “more forgiving” due to its inherent passive adaptive nature. That is, there are fewer motors than there are joints in the hand, which makes the hand move in such a way that it better “wraps” to its environment.”We don’t need to know as much about the environment as you normally would,” he said.

One notable advance in the design is that the device also has a camera that tracks in real time the position of the object that it’s manipulating.

“By coupling the adaptive nature of the hand and this external feedback, we were able to control the hand purely from vision, and without touch sensors,” Morgan said. “We use the feedback from this camera, so that it’s always saying ‘Hey you just took an action—how good was that action, and how can we make sure that the next action will be better?'”

The tool was effective at manipulating variously shaped items, such as a sphere, a toy automobile, a plastic rabbit, and a plastic duck.

In-hand manipulation tasks that have historically been very challenging for a robot to realize were “completed” by the team, according to Morgan.

Expanding on the experiment, Morgan stated that they would like to use a wider range of things to test the device’s capabilities.

Testing in-home chores would be interesting and important since, in the end, we’re attempting to produce more capable service robots, he said. He said that this might entail picking up plates or handling and putting a brush in a holder.