Introduction

The Role of AI in JIT Manufacturing, in today’s fast-paced industrial landscape, manufacturers strive to eliminate waste, reduce costs, and improve efficiency. Just-in-Time (JIT) manufacturing, a strategy developed by Toyota, aims to achieve these goals by minimizing inventory and producing goods only when needed. However, JIT systems are highly sensitive to disruptions, making optimization crucial. Enter artificial intelligence (AI), which is revolutionizing JIT manufacturing by predicting demand, enhancing supply chain efficiency, and minimizing production risks. But how exactly do AI models optimize JIT manufacturing? Let’s explore!

Understanding Just-in-Time (JIT) Manufacturing

JIT manufacturing is all about efficiency. Instead of stockpiling materials, companies order and produce exactly what’s needed, when it’s needed. This approach reduces inventory costs, prevents overproduction, and enhances overall workflow. However, it also comes with risks any supply chain delay can halt production entirely.

The Role of AI in JIT Manufacturing

AI brings intelligence to JIT by analyzing vast amounts of data, identifying patterns, and making real-time decisions. Here’s how AI-powered solutions optimize JIT systems:

1. Predictive Analytics for Demand Forecasting

One of JIT’s biggest challenges is accurately predicting demand. AI-driven predictive analytics use historical data, market trends, and real-time inputs to forecast demand more precisely. This prevents stock shortages or excess inventory.

2. Supply Chain Optimization

AI models enhance supply chain management by identifying the most efficient routes, predicting supplier reliability, and adjusting procurement strategies dynamically. Machine learning algorithms can pinpoint bottlenecks and recommend solutions before they cause disruptions.

3. Automated Production Scheduling

Traditional production scheduling relies on rigid rules, but AI adapts in real time. AI-driven scheduling tools optimize manufacturing timelines, ensuring raw materials arrive just in time for production, reducing idle time and improving efficiency.

4. AI-Powered Quality Control

JIT systems rely on flawless execution, and AI-driven quality control ensures that defective products don’t disrupt the production line. Computer vision and deep learning analyze products at every stage, identifying defects early to prevent delays.

5. Smart Inventory Management

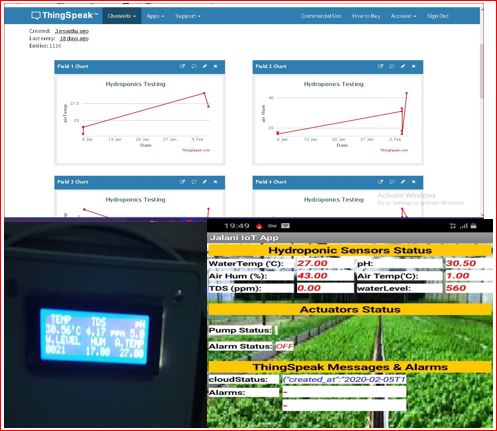

AI-based inventory systems track stock levels in real-time, automatically reordering materials when necessary. These systems integrate IoT sensors and machine learning to predict when supplies will run low, eliminating manual tracking errors.

6. Intelligent Robotics in Manufacturing

AI-powered robots streamline JIT production by handling repetitive tasks with precision. Unlike traditional automation, AI-enabled robots learn from data and adapt to changes, ensuring seamless production even when conditions fluctuate.

7. AI-Driven Supplier Risk Management

A JIT system is only as strong as its suppliers. AI models analyze supplier reliability based on past performance, geopolitical risks, and economic conditions, helping manufacturers select the most reliable partners.

8. Real-Time Data Analytics for Decision-Making

AI-powered dashboards provide real-time insights into production, supply chains, and logistics. Manufacturers can make data-driven decisions instantly, adjusting production schedules or rerouting shipments to prevent delays.

9. Natural Language Processing (NLP) for Communication

AI-powered NLP tools streamline supplier and logistics communications. These systems process emails, invoices, and supply chain messages, ensuring seamless coordination and minimizing miscommunications.

10. AI-Powered Maintenance Predictions

Unexpected machine failures can disrupt JIT systems. AI models predict equipment failures before they occur, scheduling preventive maintenance and avoiding costly downtime.

11. Reducing Waste with AI-Optimized Processes

AI identifies areas where materials, energy, or labor are wasted, recommending optimizations to make production leaner and more sustainable.

12. AI and Blockchain for Secure Supply Chains

AI combined with blockchain enhances supply chain transparency. Manufacturers can track raw materials in real time, verifying authenticity and reducing risks of fraud or supply chain manipulation.

13. Enhanced Human-AI Collaboration

AI isn’t replacing humans it’s augmenting their capabilities. AI-powered assistants help production managers analyze complex data, make informed decisions, and optimize workflows.

14. Cloud-Based AI for Scalable JIT Systems

Cloud-based AI solutions allow manufacturers to scale their JIT operations globally, integrating real-time data from multiple facilities to ensure smooth operations across different regions.

15. The Future of AI in JIT Manufacturing

As AI technology evolves, JIT manufacturing will become even smarter. Future advancements may include AI-driven market simulations, self-learning production systems, and fully automated JIT factories.

Conclusion

AI is transforming Just-in-Time manufacturing, making it more resilient, efficient, and adaptive. By leveraging predictive analytics, intelligent automation, and real-time decision-making, AI minimizes risks and enhances productivity. As AI technology advances, JIT systems will continue evolving, ensuring manufacturers stay ahead in an increasingly competitive world. Are you ready to embrace AI-powered JIT manufacturing?

Recognizing Emotional Unavailability: How to Connect with Your Partner

FAQs

1. How does AI improve demand forecasting in JIT manufacturing?

AI analyzes historical data, market trends, and real-time inputs to predict demand accurately, preventing shortages or overproduction.

2. Can AI prevent supply chain disruptions in JIT systems?

Yes, AI identifies supply chain risks, suggests alternative suppliers, and optimizes logistics to minimize disruptions.

3. What AI technologies are used in JIT manufacturing?

AI-driven predictive analytics, machine learning, NLP, computer vision, and IoT sensors enhance JIT efficiency.

4. How does AI-powered predictive maintenance help JIT systems?

AI predicts equipment failures before they happen, enabling preventive maintenance and reducing unexpected downtime.

5. Is AI in JIT manufacturing expensive to implement?

While AI adoption requires an initial investment, it ultimately reduces costs through efficiency improvements, waste reduction, and predictive insights.