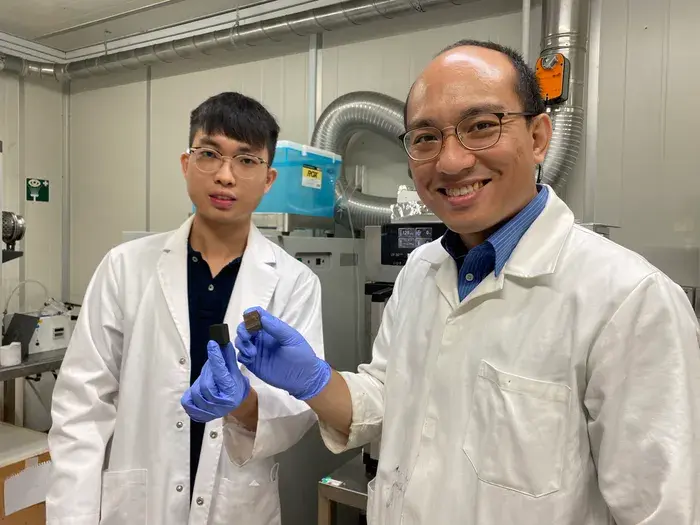

Through a process called carbonization, which converts paper into pure carbon, the Nanyang Technological University (NTU) researchers turned the paper’s fibers into electrodes, which amazingly can be made into rechargeable batteries that power mobile phones, medical equipment, and electric vehicles. In other words, converting waste papers into battery parts used in smartphones and electric vehicles

To carbonize the paper, the team began by exposing it to high temperatures, which in turn reduced it to pure carbon, water vapour and oils that can be used for biofuel. They discovered that as carbonisation takes place in the absence of oxygen, this emits negligible amounts of carbon dioxide, and this process is a greener choice to disposing of Kraft paper through incineration, which produces large amounts of greenhouse gasses.

When comparatively tested, this battery’s carbon anodes produced by the research team exhibited superior durability, flexibility, and electrochemical properties. The Laboratory tests ran on the battery showed that the anodes could be charged and discharged up to 1,200 times, when compared to other batteries is twice as durable as anodes in current phone batteries. Another interesting feature is that the batteries that use the NTU-made anodes could also withstand more physical stress than their rivals in the energy market, because it can absorb crushing energy up to five times better.

The team’s method of converting waste papers into battery parts used in smartphones and electric vehicles also adopted the use of less energy-intensive processes and heavy metals compared to current industrial methods of manufacturing battery anodes. Since the anode is worth (10–15)% of the total cost of a lithium-ion battery used in development, It is said that this latest method, which uses low-cost waste material, is expected to also bring down the cost of manufacturing energy sources.

When asked about this latest discovery by them, the team head replied; “Using waste paper as the raw material to produce battery anodes would also ease our reliance on conventional sources for carbon, such as carbonaceous fillers and carbon-yielding binders, which are mined and later processed with harsh chemicals and machinery.”

Conclusion

These team of scientists who are converting waste papers into battery parts used in smartphones and electric vehicles are very brilliant. They have identified a problem; Paper waste, which comprises disposed paper bags cardboard, newspaper, and other paper packaging, accounted for nearly a fifth of the waste generated in Singapore in 2020. Kraft paper bags alone accounts for the majority of Singapore’s paper wastes, These were found to have large environmental footprints when compared to wastes generated by cotton and plastics. Also, due to their greater contribution to global warming when incinerated and the eco-toxicity potential in their production. What a way to save the world!

So you tell us what you think? Do you think this is an amazing discovery? Can it make the global warming effect reduce in regions like Asia and Singapore to be specific? Leave us a comment in the comment section below.

You May Also Like

- RFID Bus Ticketing System Project

- Smart Irrigation Project with SMS

- How Self-Prescription Can Kill you