Introduction: Can Fungi Really Feed the Future?

When people first hear about protein made from fungi, the reaction is usually the same: Is that just mushrooms?

Not quite. Mycoprotein is a high-protein food ingredient derived from filamentous fungi, grown through fermentation rather than traditional farming. It’s already in supermarkets. But here’s the deeper question researchers and food innovators are now asking: How do we grow it smarter, faster, and more sustainably?

This is where AI-powered mycoprotein production becomes transformative. The real innovation isn’t just growing fungi—it’s using artificial intelligence to optimize every environmental variable so we can produce sustainable protein at scale without straining the planet.

What Makes Mycoprotein Sustainable in the First Place?

Fungi as Efficient Protein Factories

Unlike livestock, fungi don’t require pastureland or feed crops. They grow in controlled fermentation tanks, converting sugars into protein-rich biomass.

The benefits are striking:

- Low land use

- Reduced greenhouse gas emissions

- High feed conversion efficiency

Compared to beef or even poultry, mycoprotein production requires a fraction of the resources.

Why Scaling Is the Real Challenge

Growing fungi isn’t new. Optimizing conditions consistently across industrial fermentation systems is the hard part.

Tiny changes in temperature, oxygen levels, or nutrient balance can alter:

- Growth rate

- Texture

- Protein content

- Flavor profile

That’s where AI becomes essential.

Understanding the Biology Behind Fungal Growth

Fungi Are Sensitive to Their Environment

Fungal cells respond dynamically to:

- pH levels

- Dissolved oxygen

- Sugar concentration

- Temperature

Unlike crops in open fields, fermentation environments can be tightly controlled—but control doesn’t guarantee optimization.

Growth Is a Balancing Act

Push growth too fast, and structure weakens. Slow it down too much, and production becomes inefficient.

AI helps find the sweet spot between speed and quality.

How AI Optimizes Fermentation Conditions

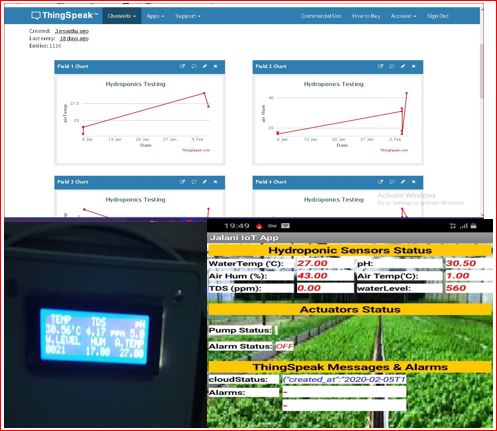

Real-Time Data Monitoring

Modern fermentation tanks generate massive streams of data. Sensors track temperature, oxygen saturation, nutrient flow, and biomass density.

AI systems analyze this data in real time to detect patterns invisible to human operators.

Predictive Adjustments Instead of Reactive Fixes

Instead of waiting for growth rates to decline, AI models predict when stress is likely to occur.

They can recommend adjustments like:

- Increasing aeration

- Modifying nutrient feed rates

- Stabilizing temperature fluctuations

This predictive control improves consistency and reduces waste.

Why Traditional Optimization Falls Short

Trial-and-Error Is Slow

Historically, optimizing fermentation meant adjusting one variable at a time and observing results.

That method is time-consuming and expensive.

Complexity Is Multi-Dimensional

Fungal growth doesn’t depend on one factor—it’s the interaction of many.

AI excels at analyzing multi-variable systems simultaneously, something humans struggle to do accurately at scale.

Improving Yield Without Compromising Texture

Texture Is Critical for Consumer Acceptance

Mycoprotein products often aim to replicate meat-like textures.

The filamentous structure of fungi creates fibrous strands that resemble muscle tissue—but only under precise growth conditions.

AI Tunes Structural Development

By analyzing microscopic growth patterns, AI models help adjust fermentation conditions to optimize fiber formation.

The result is improved mouthfeel without additives.

Reducing Environmental Impact Further

Energy Optimization

Fermentation requires energy for aeration and temperature control.

AI can reduce energy consumption by fine-tuning conditions rather than overcompensating with blanket adjustments.

Waste Minimization

Precise control reduces batch failures and overuse of nutrients.

That efficiency compounds across large production facilities.

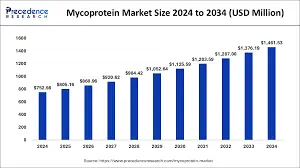

Scaling Production for Global Demand

The Protein Gap

As the global population grows, demand for protein rises. Traditional livestock systems strain land and water resources.

AI-powered mycoprotein production offers a scalable alternative that fits into urban or industrial spaces.

Consistency at Industrial Scale

Maintaining uniform quality across multiple production sites is challenging.

AI systems trained on centralized data can replicate optimal conditions across facilities worldwide.

Economic Viability and Market Competitiveness

Lowering Production Costs

Efficiency gains from AI reduce:

- Energy expenses

- Nutrient waste

- Downtime from batch failures

These savings make mycoprotein more competitive with plant and animal proteins.

Encouraging Investment

Predictable yields and reduced variability attract investors and food manufacturers.

Stability drives growth.

Safety and Quality Assurance

Monitoring for Contamination

Fermentation systems are vulnerable to microbial contamination.

AI models detect subtle anomalies in growth patterns that signal contamination early.

Standardizing Nutritional Profiles

Consumers expect consistent protein content and nutritional value.

AI ensures batches meet strict quality benchmarks.

Ethical and Environmental Implications

Reducing Livestock Dependency

Replacing even a fraction of animal protein with fungal alternatives lowers methane emissions and land conversion pressures.

Supporting Food Security

Mycoprotein production can occur close to urban centers, reducing supply chain vulnerabilities.

AI enhances reliability in this decentralized model.

Challenges Still Ahead

Data Infrastructure Requirements

AI systems depend on robust sensor networks and reliable data streams.

Smaller facilities may face upfront investment barriers.

Public Perception

Despite sustainability benefits, some consumers hesitate at the idea of fungi-based protein.

Education remains essential.

Why AI Is the Missing Link

Biology Meets Machine Intelligence

Fungi evolved to adapt to environments. AI evolved to interpret complex patterns.

Together, they form a system capable of unprecedented efficiency.

Beyond Automation

This isn’t just automated fermentation. It’s adaptive production—learning and improving with each cycle.

Conclusion: Feeding the Future Requires Smarter Systems

Mycoprotein already offers a sustainable alternative to traditional protein sources. But scaling it effectively requires more than tanks and nutrients.

AI-powered mycoprotein production transforms fermentation from a static process into a dynamic, self-improving system.

The powerful takeaway is this: when artificial intelligence meets biological intelligence, sustainable protein stops being an idea—and becomes an optimized reality.

FAQs

Is mycoprotein the same as mushrooms?

No. It comes from filamentous fungi grown through fermentation, not whole mushrooms.

Does AI control the entire fermentation process?

AI assists by analyzing data and recommending adjustments, but human oversight remains critical.

Is mycoprotein nutritionally complete?

It’s high in protein and fiber, often containing essential amino acids, though formulations vary.

Can small producers use AI optimization?

Yes, though initial sensor infrastructure may require investment.