Introduction

Imagine a world where manufacturing processes adapt instantly to changes, minimizing waste, enhancing efficiency, and personalizing production at an unprecedented scale. Thanks to artificial intelligence (AI), this vision is becoming a reality. AI-powered real-time customization in manufacturing is revolutionizing industries by enabling smart, agile, and highly efficient production systems. But how exactly does AI achieve this, and what does it mean for the future of manufacturing? Let’s dive in.

The Evolution of AI in Manufacturing

AI has come a long way in manufacturing. From basic automation to predictive analytics and now real-time customization, AI-driven technologies are redefining production lines. Traditional manufacturing relied on rigid, pre-set processes, but AI introduces flexibility, allowing systems to respond dynamically to variations in demand, materials, and even environmental conditions.

How AI Enables Real-Time Customization

AI-powered real-time customization in manufacturing relies on several key technologies:

1. Machine Learning Algorithms

Machine learning (ML) enables manufacturing systems to analyze vast amounts of data, learn from patterns, and make decisions on the fly. These algorithms optimize processes by predicting equipment failures, adjusting workflows, and enhancing product quality.

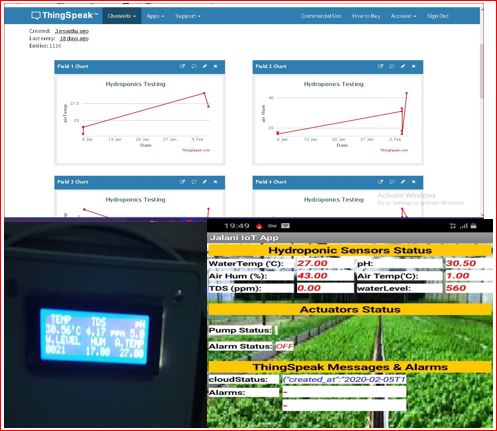

2. Internet of Things (IoT) Sensors

IoT sensors collect real-time data from machines, materials, and even the surrounding environment. This data feeds into AI models, allowing for instant adjustments to production parameters.

3. Computer Vision

AI-driven computer vision systems monitor quality control, detect defects, and even guide robotic arms in precise operations. These systems ensure that every product meets exact specifications.

4. Digital Twins

Digital twins are virtual replicas of physical manufacturing systems. AI continuously updates these digital models, simulating changes and optimizing production in real time.

5. Edge Computing

By processing data at the source (rather than relying on cloud computing), edge computing reduces latency and enhances the speed of real-time decision-making in AI-driven manufacturing.

Real-World Applications of AI in Customizing Manufacturing

Industries across the board are leveraging AI to transform their manufacturing processes. Here are a few examples:

Automotive Industry

AI-driven customization enables car manufacturers to produce personalized vehicles based on customer preferences. From adjusting seat materials to tweaking engine configurations, AI ensures efficiency without compromising quality.

Textile and Apparel Manufacturing

Fashion brands use AI to create on-demand clothing, reducing excess inventory and waste. AI can analyze trends, predict consumer preferences, and adapt production accordingly.

Electronics Manufacturing

AI optimizes circuit board assembly by adjusting machine settings in real time, ensuring high precision and minimizing defects.

Food and Beverage Industry

AI enables customization in food production, such as altering ingredients based on dietary preferences or optimizing packaging to reduce material waste.

Benefits of AI-Powered Real-Time Customization

1. Increased Efficiency

AI reduces downtime, optimizes workflows, and ensures maximum resource utilization, leading to higher efficiency and productivity.

2. Enhanced Quality Control

By continuously monitoring production, AI detects defects instantly, minimizing waste and ensuring only top-quality products reach consumers.

3. Cost Reduction

AI-driven customization reduces material waste, prevents machine failures, and minimizes human errors, cutting overall production costs.

4. Sustainability

Manufacturers can implement eco-friendly practices by optimizing energy usage and reducing waste through AI-powered decision-making.

5. Faster Time-to-Market

AI allows for rapid prototyping and flexible production, enabling manufacturers to bring new products to market faster.

Challenges and Limitations of AI in Manufacturing

Despite its advantages, AI in real-time customization presents some challenges:

High Initial Investment

Implementing AI-powered systems requires significant capital for software, hardware, and training.

Data Privacy and Security Concerns

Manufacturing systems handle sensitive data, making cybersecurity a critical concern.

Workforce Adaptation

AI adoption requires workforce upskilling, as traditional manufacturing jobs evolve into more tech-centric roles.

Integration with Legacy Systems

Many manufacturers operate with outdated systems that may not seamlessly integrate with AI technologies.

Future Trends in AI-Powered Manufacturing Customization

The future of AI in manufacturing looks promising, with several emerging trends set to redefine the industry:

Hyper-Personalization

AI will enable hyper-personalized production, catering to individual customer preferences on a massive scale.

Collaborative AI and Human Workforce

Rather than replacing humans, AI will work alongside them, enhancing decision-making and operational efficiency.

Autonomous Factories

Fully autonomous manufacturing facilities powered by AI-driven robots and predictive analytics are on the horizon.

Blockchain for Transparent Supply Chains

Combining AI with blockchain technology will improve traceability and accountability in manufacturing.

Conclusion

AI-driven real-time customization is revolutionizing manufacturing, bringing unprecedented efficiency, quality, and flexibility. As AI continues to evolve, industries must adapt to harness its full potential. The future of manufacturing is smarter, more sustainable, and incredibly dynamic all thanks to AI.

FAQs

1. How does AI improve real-time customization in manufacturing?

AI analyzes real-time data, predicts trends, and adjusts production processes instantly, ensuring efficiency and personalization.

2. What industries benefit the most from AI-powered customization?

Industries such as automotive, textiles, electronics, and food production benefit significantly from AI-driven real-time customization.

3. Is AI in manufacturing expensive to implement?

While initial investment costs can be high, AI eventually reduces operational expenses, leading to long-term cost savings.

4. How does AI impact workforce requirements in manufacturing?

AI shifts workforce needs from manual labor to tech-driven roles, requiring reskilling and upskilling of employees.

5. What are the biggest challenges of AI in real-time manufacturing customization?

Challenges include high implementation costs, cybersecurity risks, integration with legacy systems, and workforce adaptation.

Integrating IoT with Blockchain for Supply Chain Transparency