3D printing filament recycling is no longer a fringe idea discussed only in eco-forums or maker basements. It has quietly become one of the most practical answers to a growing problem in additive manufacturing: waste. If you’ve ever watched a printer chew through meters of filament only to produce a warped part, a spaghetti mess, or a failed support structure, you already understand the frustration. The question many people now ask is simple—what happens to all that plastic?

This article argues that recycling 3D printing waste is not just an environmental obligation, but an economic and technological opportunity. When we look closely at how waste is generated, reused, and redesigned, a bigger pattern emerges. Failed prints are not the end of the manufacturing cycle. In many cases, they are the beginning of a smarter one.

The Hidden Waste Problem in 3D Printing

Why 3D printing creates more waste than people expect

At first glance, 3D printing seems efficient. You only print what you need, right? In reality, additive manufacturing produces waste in subtler ways.

- Failed prints due to calibration errors

- Support structures removed after printing

- Rafts, brims, and skirts

- Test prints and prototypes

- End-of-spool leftovers

Over time, these scraps accumulate. For hobbyists, it might be a box under the desk. For print farms or universities, it can be kilograms per week.

Is 3D printing environmentally friendly?

This is one of the most searched questions—and the honest answer is: it depends. 3D printing reduces waste compared to subtractive manufacturing, but only if material reuse is considered. Without recycling, the environmental benefit is incomplete.

Understanding 3D Printing Filament Materials

Which filaments can actually be recycled?

Not all filaments behave the same way when recycled. Understanding material science matters here.

- PLA (Polylactic Acid): Technically biodegradable, but only in industrial conditions

- ABS: Fully recyclable, but releases fumes when reheated

- PETG: Recyclable and relatively stable

- HDPE and PP blends: Less common but highly reusable

PLA recycling myths and realities

PLA is often marketed as eco-friendly, which leads many users to assume it naturally decomposes. In reality, PLA behaves like traditional plastic unless processed in controlled composting facilities.

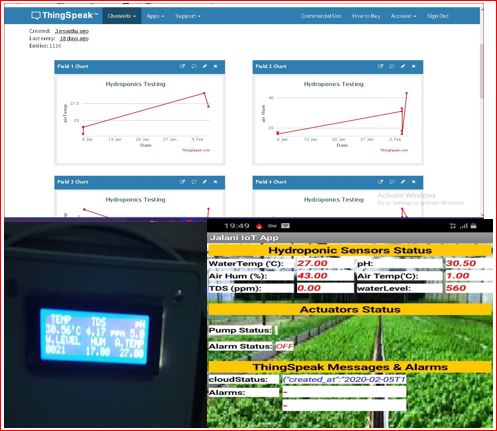

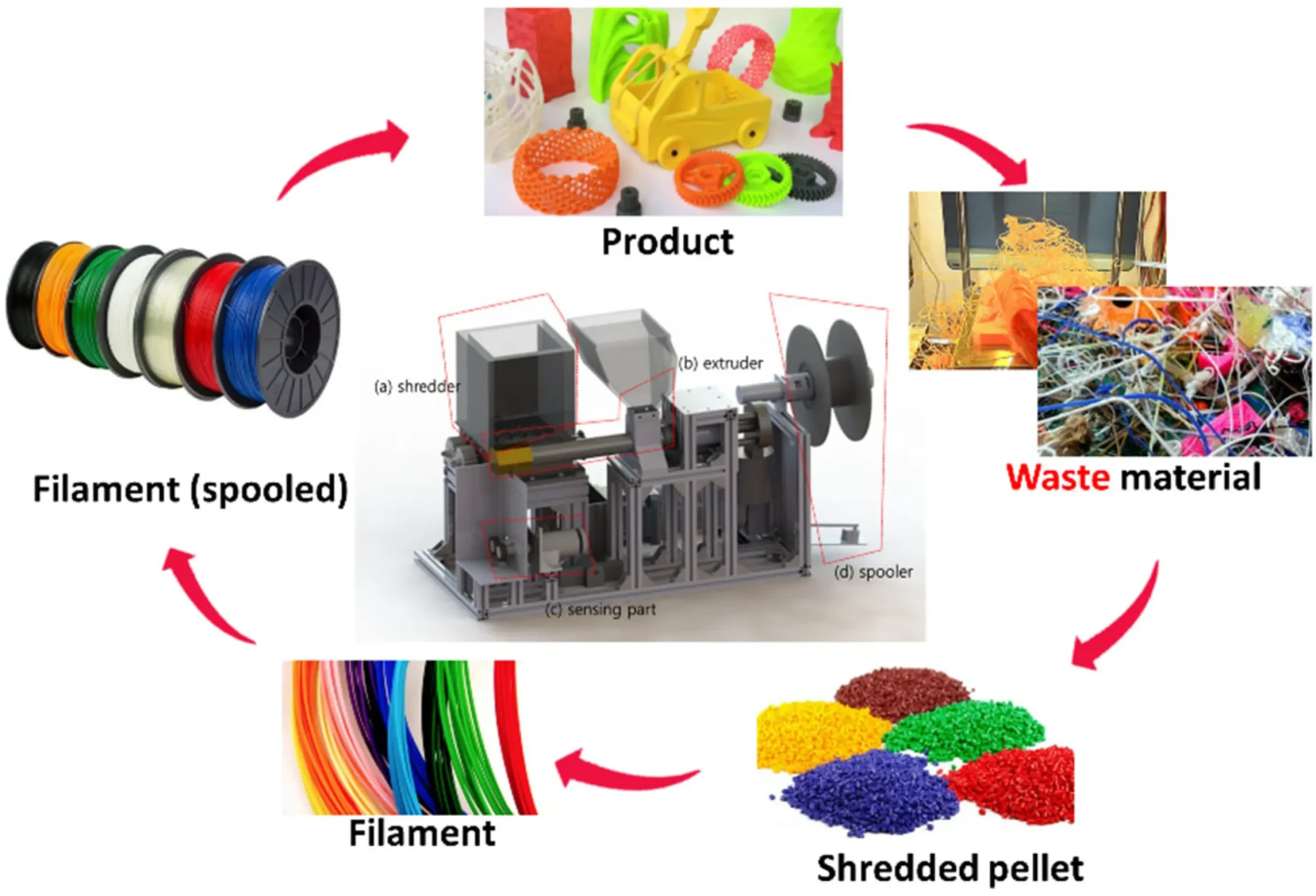

How 3D Printing Filament Recycling Actually Works

The basic recycling loop

- Collection of waste prints

- Sorting by material and color

- Shredding into plastic flakes

- Drying to remove moisture

- Extrusion into new filament

Each step affects final filament quality. Skipping steps often leads to brittle or inconsistent filament.

Home recycling vs industrial recycling

Home recycling systems appeal to makers who want independence, while industrial recycling benefits from precise temperature control and consistent filament diameter.

The Economics of Recycling 3D Print Waste

Is recycling filament actually cheaper?

For individuals, savings grow with print volume. For businesses, waste reduction lowers operating costs and improves sustainability positioning.

Why print farms are adopting recycling first

When margins are tight, throwing away material feels irresponsible. Recycling turns waste into inventory.

Recycling 3D Print Waste and Quality Concerns

Does recycled filament print worse?

If process control is poor, yes. If managed properly, recycled filament performs reliably, especially when blended with virgin material.

How many times can filament be recycled?

- PLA: 3–5 cycles

- ABS: 5–7 cycles

- PETG: 4–6 cycles

The Bigger Sustainability Picture

3D printing waste disposal vs circular design

Recycling changes how designers think. Those who plan for reuse minimize supports and optimize geometry.

Why recycling alone is not enough

Recycling is reactive. Circular manufacturing is proactive.

A Contrarian Insight: Recycling Is a Design Problem, Not a Plastic Problem

The real issue is design behavior. Failed prints often stem from poor tolerances and over-complex geometry, not bad material.

Practical Ways You Can Start Recycling Today

For hobbyists and students

Separate materials, keep scraps clean, and partner with local maker spaces.

For labs and small businesses

Label waste bins, track volumes, and test recycled filament on non-critical parts.

The Future of 3D Printing Filament Recycling

Smart recycling systems

AI-assisted extrusion and real-time monitoring are reducing skill barriers.

Policy and education

Universities and innovation hubs are likely to lead adoption.

Conclusion: Why Recycling Failed Prints Changes Everything

Recycling turns failure into feedback. It reduces cost, improves sustainability, and encourages better engineering habits.

Frequently Asked Questions

Can all 3D printing waste be recycled?

No. Materials must be sorted, and composites are often unsuitable.

Is PLA better than ABS for recycling?

PLA is easier to process; ABS lasts longer across cycles.

What happens if you mix different filaments?

Mixed plastics usually produce weak filament.

Are there services that recycle 3D print waste?

Yes, some regional and commercial programs exist.

Does recycled filament damage printers?

No, if properly filtered and dried.