Have you ever looked at a field of freshly tilled soil and wished you had a “crystal ball” that could tell you exactly how the next six months would play out? Every farmer knows the feeling. It’s that nagging question at the back of your mind: “If I plant this hybrid today, but we get a late frost and a dry July, will I still break even?” For generations, answering that question was a mix of gut instinct, historical records, and a fair amount of prayer.

But what if you didn’t have to guess? What if you could “grow” your entire season in a virtual world—testing different seeds, fertilizers, and irrigation schedules—all before a single tractor leaves the shed?

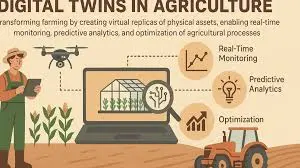

This isn’t science fiction. We are entering the era of the Digital Twin. My thesis is simple: The Digital Twin is not just a high-tech map; it is a virtual time machine that shifts the farmer’s role from a gambler against nature to a grand strategist of biological systems. By creating a digital replica of your land, you aren’t just looking at data; you are rehearsing the future.

The Flight Simulator for the Farm: What Exactly is a Digital Twin?

To understand a digital twin, we need to move past the idea of simple “precision agriculture.” You’re likely already using GPS and maybe some variable-rate tech. A Digital Twin is the next evolution.

Think of it like a flight simulator. A pilot doesn’t learn to handle a crosswind landing in a $100 million Boeing 737; they do it in a simulator where mistakes don’t cost lives or money. In the same way, a digital twin is a multi-layered, dynamic digital model of your specific field that behaves exactly like the real thing.

Moving Beyond Static Maps

Most digital tools we’ve used in the past were “static.” You looked at a soil map from three years ago or a satellite image from last week. A digital twin is “live.” It’s a bridge between the physical and virtual worlds, fueled by a constant stream of data from sensors, drones, and satellites. When it rains on your corn in the “real world,” the soil moisture levels in your digital twin update instantly.

The Mirror Effect: Physical vs. Virtual

The beauty of this technology lies in its reciprocity. We create the twin by feeding it every bit of “DNA” your field has—topography, soil chemistry, drainage patterns, and micro-climate history. Once that mirror image is established, we can use AI to run “stress tests” on it.

The Anatomy of a Digital Field: Building the Foundation

How do we actually build this thing? You can’t just point a camera at a field and call it a twin. It requires a “sandwich” of data layers, each one providing a different piece of the puzzle.

Layer 1: The Geological Skeleton

First, we need the “bones” of the field. This involves high-resolution 3D topographical mapping. We use LiDAR (Light Detection and Ranging) to understand exactly how water moves across your land. Why does that one corner always stay soggy? Your digital twin knows because it sees the two-inch dip in elevation that is invisible to the naked eye.

Layer 2: The Soil’s Bio-Chemical Profile

Next, we add the “blood” and “organs.” This is where IoT soil sensors come in. We aren’t just talking about a one-time soil test. We’re talking about probes that live in the ground, measuring nitrogen levels, pH, and moisture at different depths in real-time. This allows the digital twin to simulate how nutrients will leach or move based on different rainfall scenarios.

Layer 3: The Historical Climate Engine

Finally, we add the “memory.” We feed the model twenty to thirty years of hyper-local weather data. This allows the twin to understand the specific weather quirks of your valley or hilltop. It knows that your “average” year doesn’t exist, and instead helps you plan for the “likely” extremes.

The Power of “What-If”: Running the Time Machine

This is where the magic happens. Once the twin is built, we can start the simulations. This is the “Before You Plant” phase that changes everything.

Scenario A: The Variable Planting Date

Suppose you’re debating whether to plant early this year. You can tell your digital twin: “Simulate a planting date of April 15th with a 15% chance of a late May frost.” The twin runs the numbers, calculates the crop’s development stage at the time of the frost, and tells you your projected yield loss. Then, you run the simulation for April 25th. You might find that waiting ten days increases your profit margin by 8% by reducing risk.

Scenario B: The Fertilizer Optimization

We all know fertilizer is one of your biggest expenses. Using the twin, you can simulate different application rates. What happens if you cut nitrogen by 10% in the high-yield zones but increase it in the low-performing areas? The twin can simulate the nutrient uptake of the plants and tell you if the cost savings on the fertilizer are worth the potential dip in bushels per acre.

The Economic Logic: Why This Isn’t Just for “Big Ag”

I know what you’re thinking: “This sounds expensive. Is this only for the guys farming 10,000 acres?” In the past, maybe. But the cost of sensors and cloud computing is plummeting.

Calculating the ROI of a Mistake

The best way to look at the cost of a digital twin is to look at the cost of a mistake. If a digital twin prevents you from over-applying $5,000 worth of chemicals that would have just washed away in a predicted rainstorm, the system has paid for itself.

Reducing the “Risk Premium”

Banks and insurance companies are starting to take notice of this too. If you can show a lender a digital simulation that proves your management plan is robust against drought, you are a much lower risk. We are moving toward a future where “data-backed farming” gets you better interest rates and lower insurance premiums.

Sustainability and the “Precision” Promise

We talk a lot about “sustainability,” but it’s a hard goal to hit when you’re flying blind. Digital twins make sustainability a byproduct of efficiency.

Water Stewardship in the Virtual World

If you’re in a region where irrigation is king, a digital twin is your best friend. It can simulate evapotranspiration rates—how much water your plants are actually breathing out—based on the wind speed and humidity predicted for next week. You can “practice” your irrigation schedule in the twin to see exactly how much water reaches the root zone and how much is wasted.

Carbon Sequestration and Soil Health

Are you looking into carbon credits? A digital twin can simulate how different cover crops or no-till practices will affect your soil’s carbon content over the next five years. It gives you a roadmap to soil health that you can verify with data, making your land more valuable in the long run.

Overcoming the “Data Silo” Hurdle

If there is a “villain” in the story of digital twins, it’s fragmented data. For a twin to work, your tractor needs to talk to your soil probes, and your soil probes need to talk to your weather station.

The Importance of Interoperability

We’ve all dealt with software that doesn’t play nice with others. To build a successful digital twin, you have to prioritize open-source platforms or systems with strong APIs (Application Programming Interfaces). You don’t want your data trapped in a proprietary “walled garden” where you can’t move it between your simulation engine and your planting monitor.

The Role of the Human in the Loop

I want to be very clear: the digital twin does not replace the farmer. It is a tool, not a pilot. You still need your “boots on the ground” to verify what the sensors are saying. If the twin says the soil is dry, but you’re standing in a puddle, you know there’s a sensor malfunction. The twin provides the foresight, but you provide the judgment.

The Technological Frontier: Where are We Heading?

We are just scratching the surface of what’s possible. As we look five to ten years down the road, the digital twin will become even more autonomous.

Edge Computing and Real-Time Adjustments

Imagine your sprayer moving through the field. Its “digital twin” is running in its onboard computer, processing data from cameras that see every individual weed. The twin simulates the best chemical mix for that specific square foot and adjusts the nozzles in milliseconds. We aren’t just simulating the season; we are simulating every second of the operation.

Synthetic Data and “Blind” Simulations

In the future, we will use synthetic data to fill in the gaps where we don’t have sensors. AI will look at ten million acres of similar soil types across the globe to predict how your specific field will behave, even if you’ve only just started collecting data. This will lower the “barrier to entry” for new farmers or those moving to new crops.

The Synthesis: Transforming Fear into Strategy

Farming has always been a high-stakes game played against an opponent (Nature) that doesn’t play fair. The anxiety of the “unknown” is a heavy burden to carry.

The Digital Twin changes the fundamental psychology of the profession. When you can run a thousand simulations of your growing season on a cold night in January, you aren’t just “hoping” for the best. You are choosing the path with the highest probability of success. You are moving from a reactive state—constantly putting out fires—to a proactive state where you’ve already “beaten” the drought in a simulation five months ago.

The unique angle here is that the Digital Twin isn’t about the technology; it’s about certainty. It’s about giving you the confidence to innovate, to try new crops, and to push the limits of your land without betting the entire farm on an unproven idea.

FAQs

1. How much data do I need before my Digital Twin becomes accurate?

You can start with basic topography and historical weather data immediately, but the “sweet spot” for accuracy usually comes after two to three years of consistent sensor data. This allows the AI to learn the specific “personality” of your soil and how it responds to your local micro-climate.

2. Do I need a high-speed internet connection in the field for this to work?

While a constant connection is ideal for “real-time” updates, it’s not a dealbreaker. Many systems use Edge Computing, where the data is processed locally on a device in the field or the tractor, and then synced to the main “twin” whenever you return to a Wi-Fi signal.

3. Can a Digital Twin help with pest and disease management?

Absolutely. By simulating humidity levels and leaf wetness duration, the twin can predict the outbreak window for specific fungi or pests. You can run a simulation to see if a preventative spray now is more cost-effective than a curative one later.

4. What is the “Digital Twin” of a seed?

In these simulations, we use “Digital Seed Profiles.” These are datasets provided by seed companies (or built from your own yield maps) that describe how a specific hybrid grows—how much water it needs, its heat units to maturity, and its resistance to specific stresses.